Crysound 2623 – Acoustic Imager

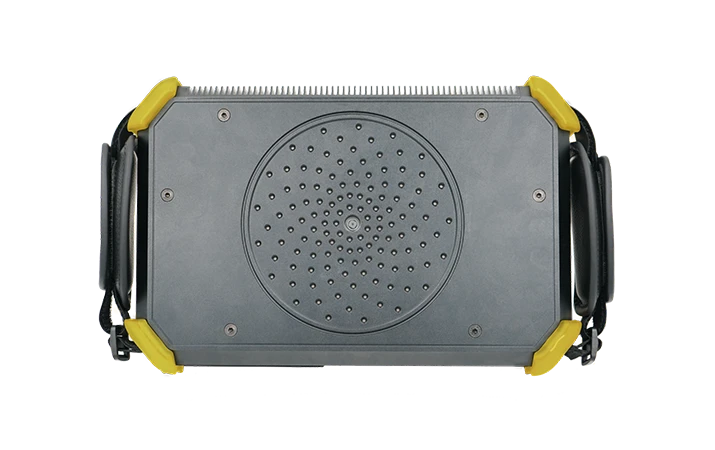

Unlock efficient fault detection with the Crysound 2623: a versatile acoustic imager that excels in identifying gas leaks and partial discharges. Tailored for industrial use, it merges high-definition imaging with intuitive controls to enhance maintenance workflows in challenging environments.

Crysound 2623: Handheld Acoustic Imaging Camera

Discover the Crysound 2623, the latest advancement in hand-held industrial acoustic imaging technology. Crafted to bridge the gap between complexity and user-friendliness, the Crysound 2623 offers a seamless integration of high-definition visual imaging with sophisticated acoustic data analysis.

This powerful tool is designed to detect and diagnose:

- Air leaks

- Gas leaks

- Vacuum leaks

- Electrical discharges

With its robust aluminum alloy construction, the Crysound 2623 stands ready to tackle the demands of any work site, providing clear, actionable insights through its dynamic display. Step into the future of maintenance and inspection with a device that’s as versatile as it is precise.

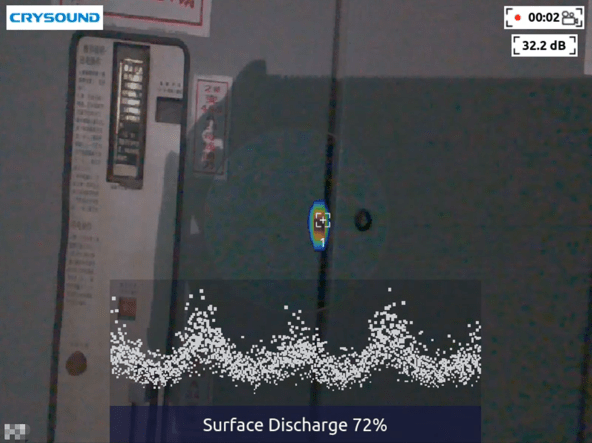

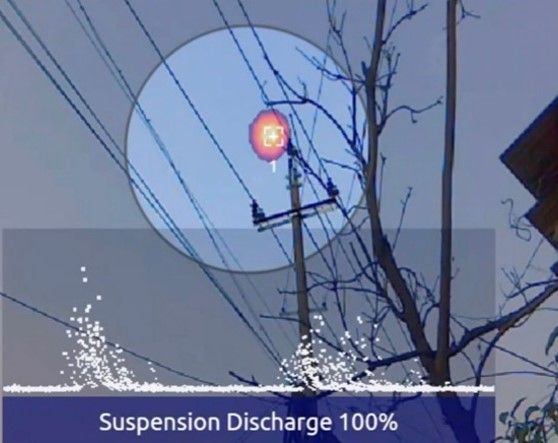

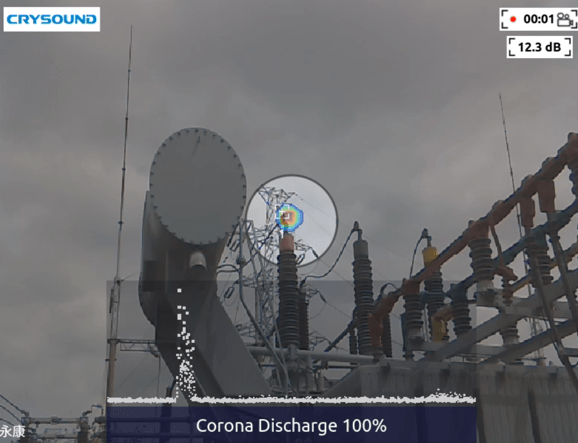

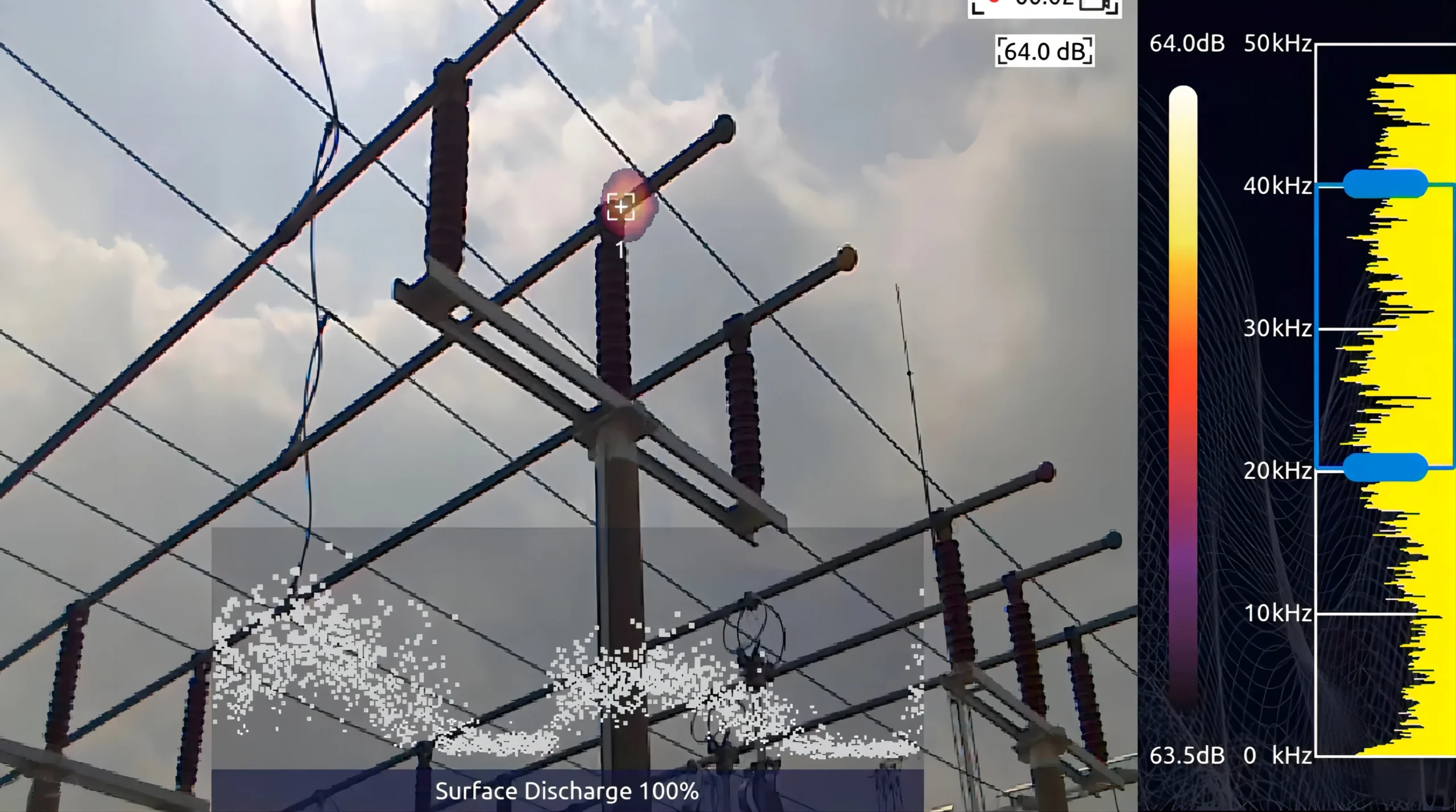

Partial Discharge Detection

When it comes to safeguarding electrical systems, early detection of partial discharges is crucial. The Crysound 2623 excels in this area, offering a specialized solution for identifying electrical partial discharge faults within power systems.

This industrial acoustic imager, with its dual-functionality for both gas leak and partial discharge detection, showcases an impressive ability to capture and visually represent changing sound sources associated with electrical faults.

Ideal for preventive maintenance, the Crysound 2623 aids in averting potential system failures, thus maintaining the integrity and reliability of power infrastructures. With the Crysound 2623, professionals can approach electrical maintenance with confidence.

Gas Leak Detection

The Crysound 2623, equipped with advanced ultrasonic frequency band capabilities, is a handheld imager tailor-made for pinpointing the most elusive gas leaks in industrial settings.

By harnessing microphone array beamforming technology, the Crysound 2623 captures sound source distribution data, overlaying this information on real-time video images.

This method proves especially effective in noisy environments where traditional detection methods fail. Whether it’s for routine inspections or emergency leak identification, the Crysound 2623 is an essential tool for ensuring workplace safety and operational continuity.

Crysound 2623 Key Features

- Beamforming Microphone Array: For precise sound localization and detection.

- Durable Aluminum Alloy Shell: Built to withstand industrial environments.

- Dual Detection Functionality: Capable of identifying both gas leaks and partial discharges.

- Large Capacity Storage: Facilitates extensive data recording and export.

- Leak Assessment Function: Offers on-device evaluation of leak severity and volume.

- One-Click Report Generation: Simplified reporting with PC-based software.

- Ultrasonic Monitoring: Enhances detection of ultrasonic frequency bands.

- Multilingual User Interface: Supports English, Korean, and French for broader accessibility.

- Flexible Recording Modes: Adapts to various operational needs with camera and video options.

Focus Function: Targeting Precision

The focus function on the Crysound 2623 is a critical feature for accurately identifying and isolating specific issues like partial discharges and leaks. By narrowing the detection field, this function allows for precise localization of indications.

Ideal for complex industrial settings, activating the focus function streamlines the diagnostic process, enabling a more efficient and targeted approach to maintenance.

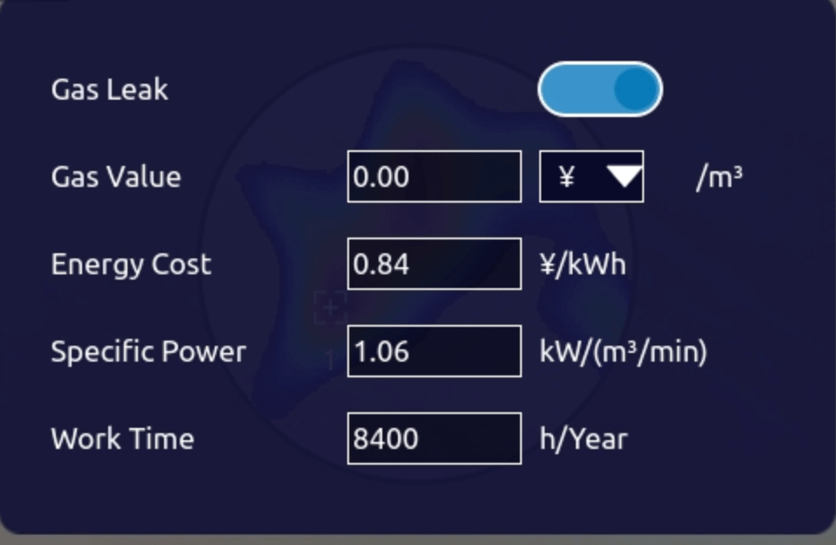

Leak Rate Qualification

The Crysound 2623 stands out with its capability to not only detect leaks but also to provide quantitative estimates of leak flow rates. This sophisticated acoustic imager presents the calculated leak levels directly on its display, offering users immediate insights into the severity of the leak.

Additionally, it calculates and shows the corresponding economic value of the losses incurred, enabling a more informed decision-making process.

This feature is invaluable for industries looking to minimize waste and reduce operational costs, making the Crysound 2623 an essential tool for efficient resource management and financial accountability.

Discharge Fault Diagnoses with PRPD Mapping

The Crysound 2623 features PRPD (phase-resolved partial discharge) mapping function, enabling precise fault diagnosis in electrical equipment. This analysis tool measures discharge pulses, using discharge count and phase difference as coordinates to identify and locate faults.

By interpreting the PRPD spectrum, users can quickly detect and address various fault types, ensuring effective maintenance and enhancing the reliability of power systems. This capability is crucial for minimizing downtime and maintaining operational safety.

Intrinsically Safe Alternative: Crysound 2624

The Crysound 2624 is an ATEX-certified acoustic imager crafted for environments requiring explosion-proof equipment. Ideal for the chemical and energy sectors, this robust device features an aluminum alloy shell designed to withstand complex and hazardous conditions. The Crysound 2624 provides a reliable and secure solution for operations where safety cannot be compromised.