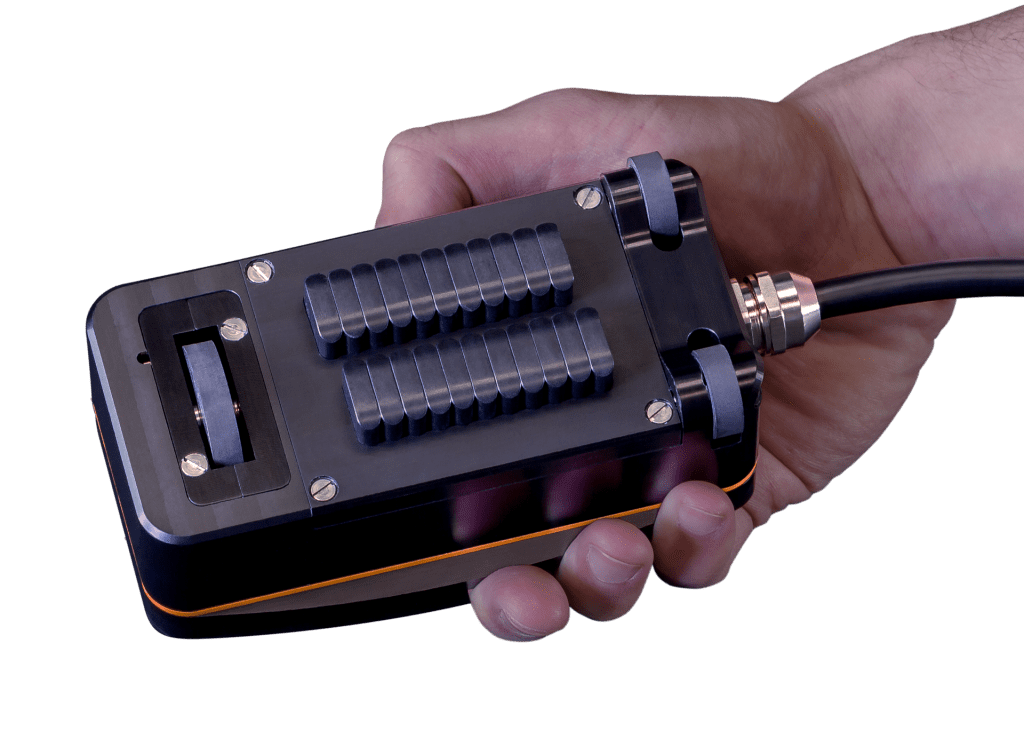

Description

The innovative design of the patented Sharck probes is capable of addressing the inspection needs of several industries relying heavily on carbon steel, such as the onshore and offshore oil and gas, wind power, and structural industries.

Sharck is specifically designed for cracking in carbon steel using tangential eddy current array (TECA™) technology. These probes are capable of positioning cracks, measuring their length, and sizing them as deep as 7 mm (0.28 in). This can be achieved without removing paint or protective coatings, unlike more conventional techniques.

Benefit 1 — Advanced Array Technology

- Incorporates tangential eddy current array (TECA)

- Fast — Up to 600 mm/s (2 ft/s) depending on the probe model

- Single-pass detection of longitudinal and transverse cracks

- Wide coverage

- High-performance multiplexing for optimal sensitivity

- Reliable, less operator dependent compared to alternatives

Benefit 2 — Advanced Software

- Easy interpretation with intuitive encoded 2D/3D C-scans

- Actual crack depth measurements — Not based on theoretical modelling

- Automatic readings — Crack length and depth, liftoff

- Auto-compensation — Live monitoring of liftoff and permeability variations

- Full data recording and archiving capabilities

Benefit 3 — In Line With Recognized Eddy Current Certifications and Standards

Sharck probes return signals similar to conventional eddy current testing signals, making the technology easy to learn. The probes also comply with ASTM E3052.

Reviews

There are no reviews yet.