Guide

The DJI Ban Explained: What You Need to Know [New for 2026]

Is there a DJI ban in the U.S.? No, there is not a blanket ban on DJI drones.

→ Jump to all the DJI drones currently available from MFE.

Already-launched DJI drones can still be imported and sold. However, in the future when DJI launches new drones, they will currently not be allowed to import or sell them in the U.S.

Right now, professional drone pilots can still get DJI drones, including:

Key facts for enterprise and inspection operators:

- Existing DJI drones are not grounded. DJI platforms that already received FCC approval remain legal to import, sell, and operate in the U.S. This includes all the models listed above, as well as any other DJI drones that have already been sold in the U.S.—if it was sold before, it can still be sold.

- New DJI drones are blocked. Any future DJI drone that does not already have FCC authorization cannot be approved, imported, or sold under current rules.

- This is a supply-chain restriction—not an FAA flight ban. There has been no grounding order, remote disablement, or change to Part 107 operations for existing DJI aircraft.

- Availability is real, but finite. Inventory of approved DJI platforms will depend on remaining stock and enforcement conditions, with no path for new product refreshes.

- Inspection programs face continuity risk. The core challenge for asset owners and service providers will not be today’s flights. It’s maintaining long-term fleet consistency, training, and data workflows.

For industrial operators, this situation creates a planning challenge—not a moment of panic.

Many organizations are continuing to use DJI platforms to support active inspection programs, replace damaged aircraft, or maintain consistency across fleets. At the same time, most recognize that DJI can no longer serve as a future-proof foundation for long-term fleet growth.

This guide explains what the “DJI ban” actually does changes, which DJI platforms remain available through MFE today, and how inspection teams can reduce operational risk by planning for a mixed-fleet or post-DJI future—without disrupting ongoing work.

Keep reading for the full guide, or use the menu to the right to jump around.

DJI Drones Available from MFE

MFE Inspection Solutions continues to supply high-end DJI platforms for industrial operators.

Keep reading to see what we currently have in stock.

DJI Matrice 4

The DJI Matrice 4 is DJI’s next-generation flagship platform for complex industrial inspections.

It supports advanced payloads, long flight times, and robust redundancy, making it a strong choice for refineries, terminals, ports, and power plants that need reliable, repeatable inspection workflows.

- High-end flight performance and long endurance for extended missions.

- Support for multi-sensor payloads to capture visual, thermal, and other data in a single flight.

- Ruggedized design for harsh industrial environments.

- Tightly integrated with DJI’s enterprise software ecosystem for planning and data management.

DJI Matrice 30

The DJI Matrice 30 Series provides a compact, weather-resistant platform that still carries a powerful integrated camera payload.

It’s well-suited for teams that need a workhorse inspection drone that can deploy quickly from a vehicle or vessel and handle changing weather.

- Integrated zoom, wide, and (on some models) thermal sensors in a single payload.

- IP-rated airframe for operation in rain and challenging conditions.

- Designed for rapid deployment and efficient field operations.

- Common choice for inspections on stacks, flare tips, tank farms, and transmission corridors.

Buy or rent the DJI Matrice 30 Series.

DJI Matrice 300 RTK

The DJI Matrice 300 RTK is a proven workhorse for industrial and utility inspections.

With RTK positioning, long flight times, and support for multiple gimbals, it remains a staple platform for teams that need stable, survey-grade data collection.

- RTK-enabled positioning for precise flight paths and repeatable data capture.

- Support for multiple payloads, including zoom and thermal cameras.

- Long endurance for large-area or high-altitude inspections.

- Widely used for power lines, pipelines, and critical-infrastructure surveys.

DJI Matrice 350 RTK

The DJI Matrice 350 RTK builds on the M300 platform with upgraded avionics, improved flight performance, and enhanced safety features.

It’s a strong option for operators standardizing on DJI’s current-generation industrial platform.

- Improved flight performance and battery system over the M300 RTK.

- RTK support for precise path-following and repeat surveys.

- Compatible with a wide range of DJI enterprise payloads.

- Suitable for long-range, high-altitude, and BVLOS-style inspection profiles (where regulations allow).

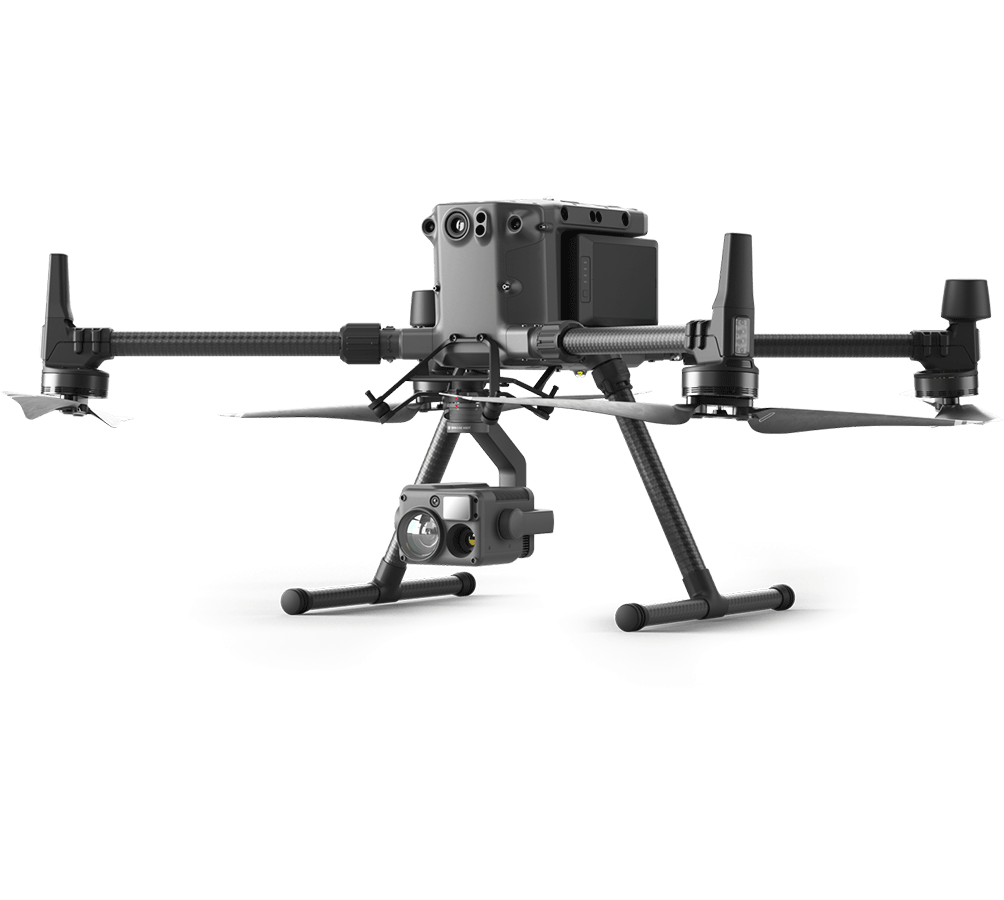

DJI Matrice 400

The DJI Matrice 400 is designed as a robust, future-facing inspection platform with support for heavier payloads and advanced workflows.

It gives asset owners and service providers an upgrade path beyond older Matrice models while maintaining compatibility with existing DJI tooling.

- Enhanced payload capacity and endurance for demanding inspection missions.

- Supports advanced sensing packages and future payload upgrades.

- Built for 24/7 industrial operations in demanding environments.

- Ideal for organizations standardizing fleets around DJI’s latest inspection platform.

Buy or rent the DJI Matrice 400.

DJI Mavic 2 Enterprise Advanced

The DJI Mavic 2 Enterprise Advanced is a compact, foldable enterprise drone that combines a visual camera with a high-resolution thermal sensor.

It remains a practical option for close-range industrial inspections, localized surveys, and rapid-response work.

- Portable, easy-to-deploy platform for field teams.

- Integrated thermal and visual cameras for dual-mode inspections.

- Good fit for facility-level checks, leak-detection support, and emergency response.

- Useful as a secondary or backup inspection platform alongside larger Matrice systems.

Rent the DJI Mavic 2 Enterprise Advanced.

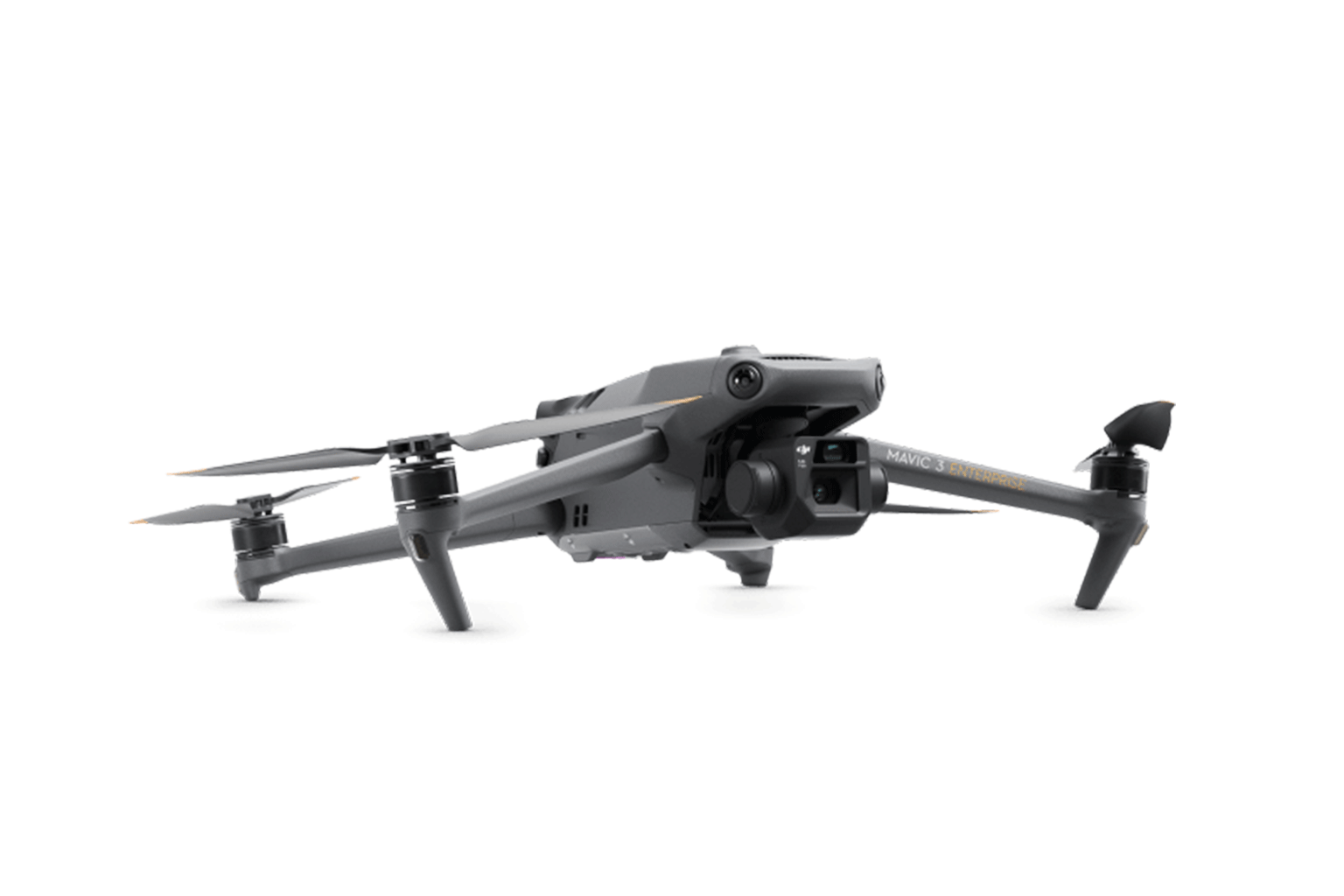

DJI Mavic 3 Enterprise

The DJI Mavic 3 Enterprise Series offers a modern, compact inspection platform with improved imaging, flight time, and safety features over older Mavic models.

It’s a strong fit for operators who need professional-grade data without a full-size Matrice system.

- High-resolution camera with powerful zoom capabilities.

- Longer flight times in a compact, foldable airframe.

- Built-in enterprise features like advanced obstacle sensing and RTK options (on some models).

- Suitable for rooftop surveys, structural inspections, and general industrial monitoring.

Buy the DJI Mavic 3 Enterprise.

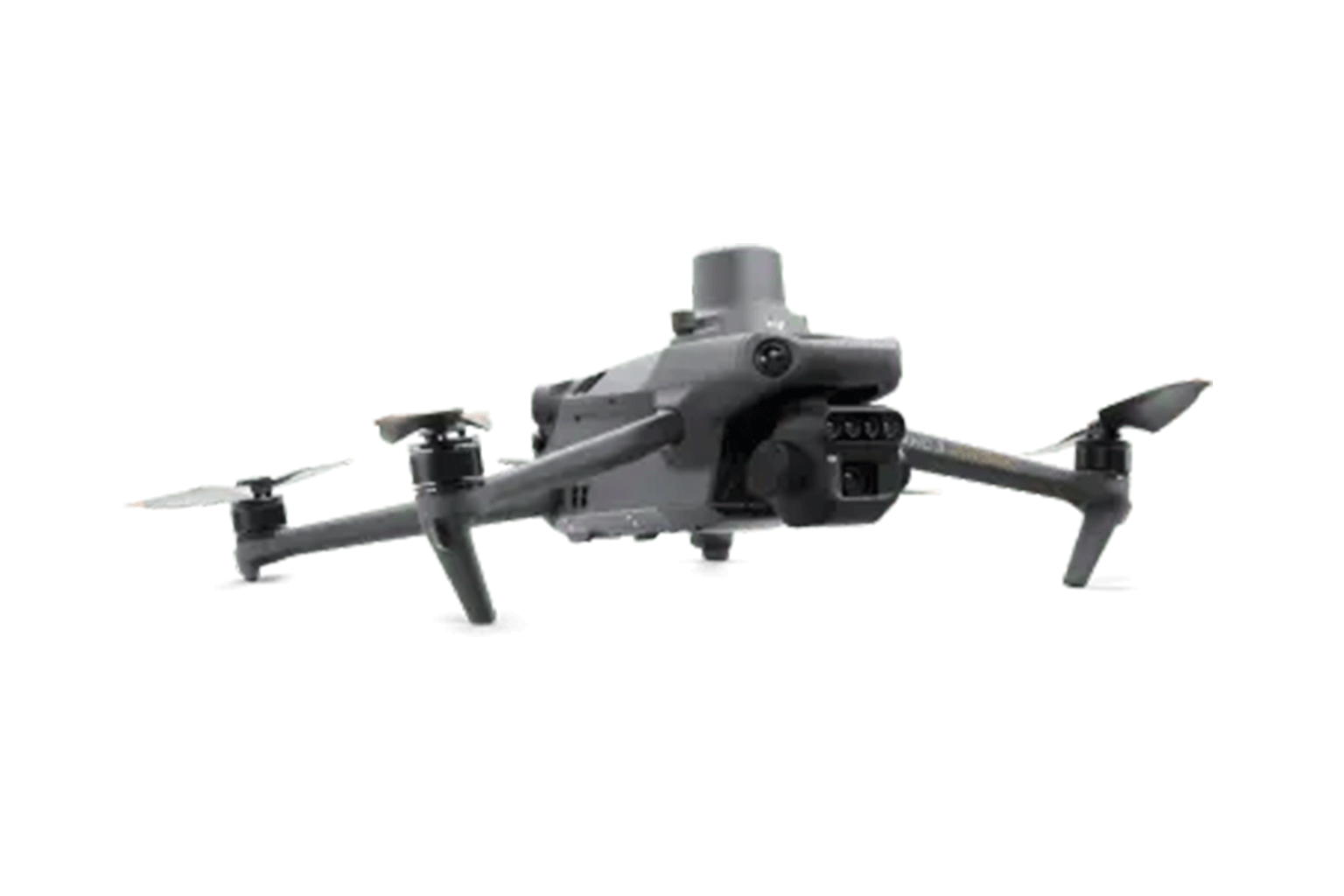

DJI Mavic 3 Multispectral

The DJI Mavic 3 Multispectral pairs a high-quality RGB camera with multispectral sensors, allowing operators to see beyond the visible spectrum.

While common in agriculture, it also has niche industrial applications where material changes or surface conditions can be tracked spectrally.

- Multispectral and RGB imaging in a single compact platform.

- Useful for right-of-way monitoring, vegetation management, and environmental surveys around industrial assets.

- Integrates with mapping workflows for orthomosaics and NDVI-style analyses.

- Foldable and easily transported between sites.

Buy the DJI Mavic 3 Multispectral.

DJI Mavic 3 Thermal

The DJI Mavic 3 Thermal is a compact thermal-imaging platform built around the Mavic 3 airframe.

It’s an efficient choice for teams that need to detect hot spots, insulation failures, or other temperature-driven anomalies around industrial facilities.

- Integrated thermal and visual cameras for detailed inspection data.

- Excellent for electrical inspections, flare and stack checks, and leak-detection support.

- Large flight-time improvements over older Mavic thermal platforms.

- Portable enough for rapid deployment from trucks, vessels, or small sites.

DJI FlyCart 30

The DJI FlyCart 30 is a heavy-lift delivery drone built for industrial logistics.

With a high payload capacity, dual-battery redundancy, and flexible cargo options (cargo box or winch), it helps teams move tools, spares, and small equipment across challenging terrain or over obstacles where ground transport is slow or unsafe.

- High payload capacity for industrial parts, tools, and consumables.

- All-weather design with robust propulsion and redundant systems.

- Configurable cargo options for point-to-point delivery in complex environments.

- Ideal for remote sites, plants with limited road access, and offshore logistics.

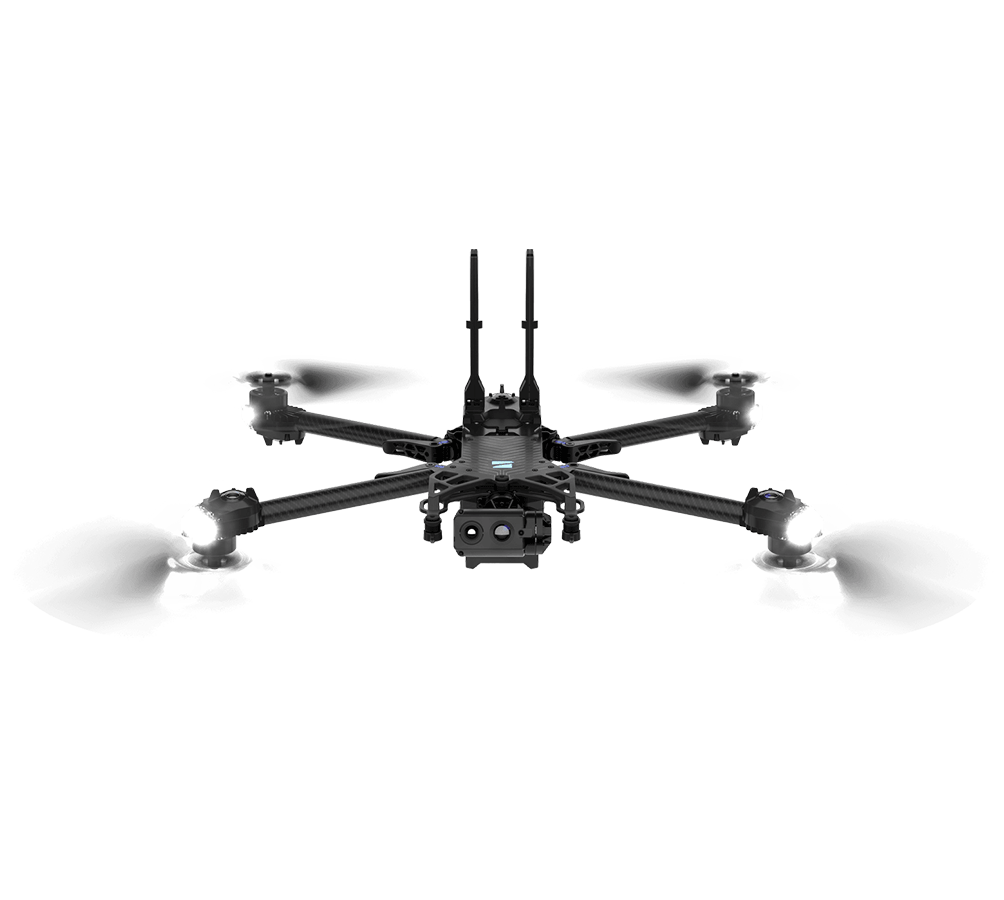

DJI Alternatives for Industrial Inspections

Even as DJI remains widely used across heavy industries, many organizations are diversifying their fleets and looking for DJI-alternatives.

Buying non-DJI drones can help professional drone programs reduce risk, meet procurement requirements, and expand capabilities, especially now that future DJI products won’t be available.

The platforms below are proven in heavy industries like oil & gas, power generation, maritime, mining, and manufacturing environments, and every model listed here is available through MFE.

Important note: These DJI alternatives are strictly professional drones. That is, they’re not consumer drones. These are purpose-built industrial systems designed for industrial inspections, confined-space entry, autonomous mapping, NDT workflows, tactical operations, and high-precision outdoor inspections.

Autonomous Outdoor Drones

Skydio X2

Skydio X2 is designed for enterprise operations requiring secure data handling, long flight times, and reliable autonomy in complex outdoor structures. It is frequently used for utility, infrastructure, and emergency-response applications.

Skydio X10

The Skydio X10 is Skydio’s newest and most capable autonomous drone, built for high-end industrial inspections. It supports swappable sensors, advanced AI navigation, and resilient flight in cluttered, wind-affected outdoor environments.

Indoor / Confined-Space Inspection Drones

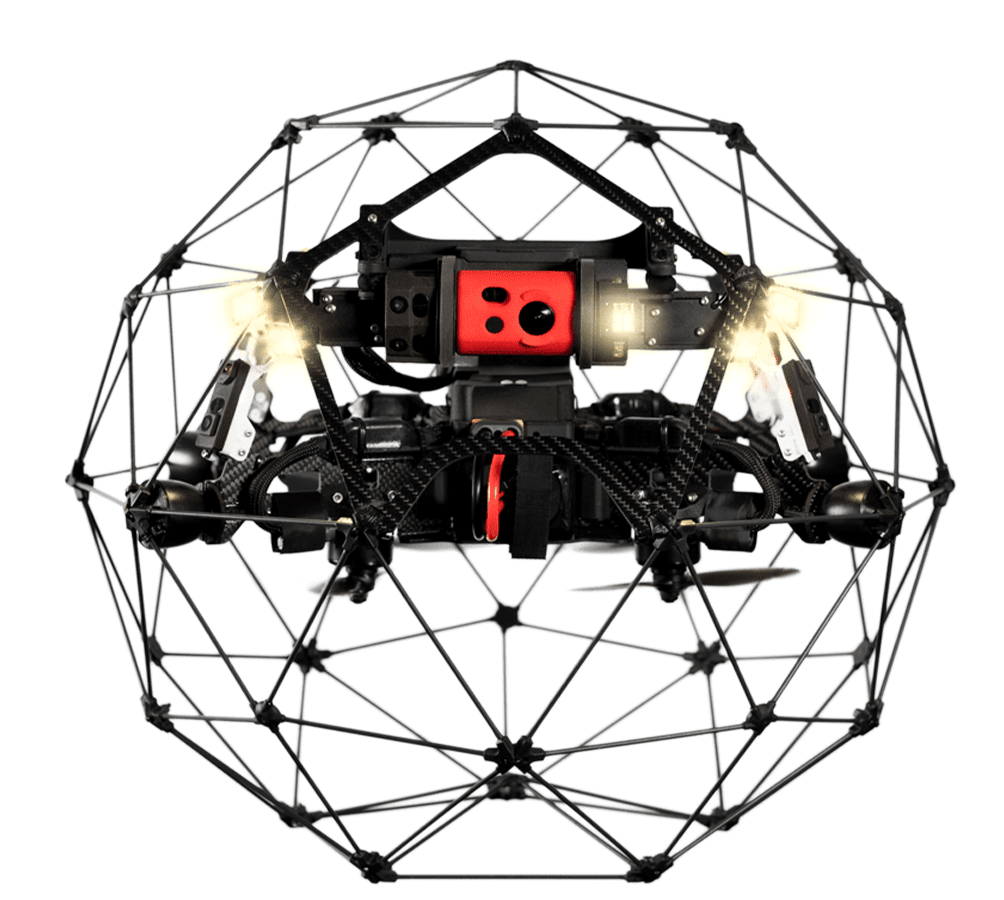

Flyability Elios 2

The Flyability Elios 2 is a collision-tolerant indoor drone engineered for tanks, boilers, pressure vessels, kilns, and other confined spaces. It allows inspectors to collect high-quality visual data without entering hazardous environments.

Buy or rent the Flyability Elios 2.

Flyability Elios 3

The Elios 3 introduces LiDAR-based 3D mapping, SLAM navigation, and payload modularity. It is widely used for digital twins, complex internal geometries, and environments where GPS is unavailable and human access is unsafe.

Buy or rent the Flyability Elios 3.

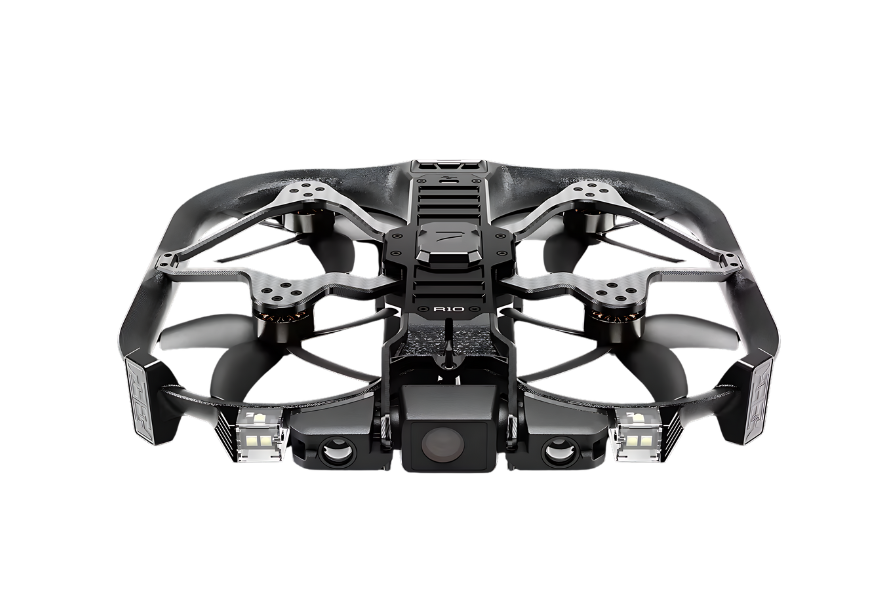

Skydio R10

Skydio R10 is a next-generation indoor inspection platform that uses advanced autonomy to navigate confined and obstacle-dense spaces. It is well suited for power plants, manufacturing facilities, and industrial interiors requiring consistent data collection.

How the DJI Ban Works (and What Actually Changed)

The DJI ban did not arrive as a single, explicit prohibition on DJI drones. Instead, it took effect through a regulatory trigger created by the 2025 National Defense Authorization Act (NDAA) and subsequent action by the FCC.

Under the NDAA, Congress required a U.S. national-security agency to complete a formal security review of DJI by December 23, 2025. The law was structured with an automatic consequence: if no agency completed the review by that date, DJI would be added to the FCC’s Covered List.

That review was not completed before the deadline.

However, instead of specifically adding DJI to the Covered List, which would have only banned DJI, the FCC moved to add all new drones made by foreign companies to the list. This action effectively blocks all new foreign-made drones from the U.S.—though it’s likely that some non-Chinese companies will be able to get exemptions and continue to sell future models of their drones in the U.S.

So What Does It Mean Right Now?

The practical outcome is not a grounding of existing drones, but a cutoff for future market entry.

DJI platforms that already received FCC authorization remain legal to import, sell, and operate. For example, since the Matrice 400 already got FCC authorization, it can still be imported and sold in the U.S.

But new DJI drone models—for example, a future Matrice 450 or 500—can no longer receive the FCC approval required to enter the U.S. market.

For industrial and inspection operators, this distinction is critical: operations continue today, but the path for future DJI hardware has closed.

The DJI Matrice 400

What Is the FCC Covered List?

The FCC Covered List identifies companies and equipment categories that U.S. regulators consider to pose potential national-security risk under telecommunications law.

Being placed on the Covered List primarily affects future market access—not equipment already in use.

Being on the Covered List list restricts:

- New equipment authorizations. DJI can no longer receive FCC approval for new drone models, radios, or covered wireless components.

- Imports of newly approved products. Without authorization, new DJI hardware cannot be legally imported for sale in the U.S.

- Long-term restocking. Once existing, previously authorized inventory is depleted, there is no pathway for replacement with newer models.

Importantly, the Covered List does not grant the FCC authority to disable, ground, or otherwise interfere with DJI drones already in service. Operators remain free to fly aircraft they legally own under existing FAA rules.

The focus is on controlling future availability—not disrupting active fleets.

Why the NDAA Trigger Matters

The NDAA’s “review-or-trigger” structure is what created the current environment.

Rather than banning DJI outright, Congress established a deadline-based mechanism that shifted the decision to the executive branch. When no agency completed the required review, the automatic consequence took effect, leading to FCC action under its Covered List authority.

This matters for operators because the restriction is lasting. Reversing it would require new federal action, such as legislation, regulatory changes, or a completed security review paired with policy relief.

Until then, the market for DJI hardware in the U.S. is effectively frozen in place.

What Changed—and What Didn’t

For inspection teams and asset owners, the immediate effects are subtle but strategically important.

- Existing DJI drones remain flyable. There has been no FAA grounding, remote disablement, or operational restriction on DJI aircraft already in use.

- Existing inventory can still be sold. DJI platforms that already received FCC authorization may continue to move through U.S. channels while stock remains.

- No new DJI models can enter the market. Future product launches and refreshes are blocked under current rules.

- Long-term support is uncertain. Over time, access to spare parts, repairs, and firmware updates may become more constrained as supply chains adjust.

Put simply, the NDAA mechanism affects the supply of future DJI equipment far more than the operation of drones already in the field.

For inspection programs planning beyond the short term, this reality makes lifecycle management, spare-parts planning, and fleet diversification strategic—not optional.

How the DJI Ban Affects Industrial Inspections

For most industrial operators, the primary concern is not whether DJI drones will suddenly become unusable—they won’t.

The bigger issue is how a restricted supply of new DJI hardware is influencing inspection planning, fleet management, and long-term risk mitigation.

Heavy industries rely on predictable workflows, standardized equipment, and stable maintenance cycles. And any disruption to procurement or support can ripple through an organization’s inspection capabilities.

Most Inspection Programs Are Built Around DJI Technology

Over the last decade, DJI platforms have become deeply embedded in industrial inspection programs.

Many teams have standardized their programs on Matrice and Mavic Enterprise systems for:

- Tank, vessel, and flare inspections

- Transmission and distribution line surveys

- Pipeline corridor monitoring

- Rooftop, structural, and right-of-way assessments

- Environmental and thermal anomaly detection

These programs rely on consistent imaging quality, predictable flight performance, and interoperability with established data-management workflows.

As future DJI models are blocked from entering the U.S. market under current rules, teams may face challenges refreshing equipment or scaling up for larger inspection workloads.

Fleet Refresh Cycles May Become Less Predictable

Industrial drone fleets are typically managed like any other critical asset—with lifecycle plans, spare units, and annual refresh budgets.

The FCC listing does not disrupt current operations, but it can make:

- Replacing aging airframes more difficult

- Maintaining consistent sensor packages across sites harder

- Standardizing training on a common platform more challenging

Organizations that operate multiple sites, or rely heavily on consistent data from year to year, may find that continuity is harder to maintain when new units cannot be procured on demand.

Supply Chains for Parts and Repairs Could Tighten

Even if existing DJI drones remain fully functional, the industrial impact becomes more pronounced as spare parts, batteries, and repair pathways begin to constrict.

Over time, operators could encounter:

- Longer lead times for repairs

- Reduced availability of batteries and mission-critical components

- Third-party repair shops facing limited access to OEM parts

For inspection programs with tight schedules—such as turnaround windows or seasonal maintenance cycles—these delays can directly affect project timelines and operational reliability.

Standardized Data Workflows Could Be Disrupted

Many industrial teams have structured their data workflows around DJI’s ecosystem, including:

- Flight planning and mission automation tools

- Payload-specific data formats

- Integration with inspection management platforms

With the market for new DJI models effectively frozen, future firmware changes, shifting support priorities, or reduced access to repairs and parts could introduce complications for organizations with long-term data-archival requirements or strict traceability processes.

The Risk Profile Shifts From “Operational” to “Strategic”

Day-to-day flight operations largely continue unchanged even with DJI on the FCC Covered List.

The bigger shift is strategic: industrial operators now need to ensure their drone programs can withstand multi-year procurement restrictions without compromising inspection quality, safety, or regulatory obligations.

Doing this may include diversifying fleets, evaluating non-DJI platforms for specific use cases, and building a more flexible refresh strategy.

What Industrial Operators Should Do Now

Now that the DJI ban mechanism is in effect, the most important thing for industrial operators is to separate day-to-day flight reality from long-term program risk.

To be clear, this is not an operational shutdown.

Existing DJI drones remain usable, and most inspection teams can keep flying without interruption.

The real change is strategic: future DJI hardware availability in the U.S. is constrained, which can affect refresh cycles, standardization, parts pipelines, and long-term planning.

That’s why we recommend taking the steps below to protect inspection continuity—especially for programs that have standardized on DJI platforms.

1. Stabilize Your Existing DJI Fleet

If your inspection workflows rely on DJI platforms, now is the time to make sure your current fleet is in its best possible condition.

This includes:

- Updating all firmware while updates remain readily available.

- Documenting flight hours and maintenance history to support lifecycle planning.

- Checking compatibility across batteries, payloads, and controllers to reduce unexpected gaps.

- Standardizing configurations across sites to simplify training and data consistency.

These steps improve operational reliability today and help teams understand which aircraft may need to be replaced or supplemented in 2026 and beyond.

2. Secure Spare Parts, Batteries, and Critical Components

When new models can’t enter the market, consumables and wear-prone parts often become the pinch point before entire airframes disappear—especially batteries, props, gimbals, landing gear, and cables.

Industrial programs should consider:

- Buying spare batteries for aircraft expected to remain in service for several years.

- Stocking propellers, gimbals, landing gear, and cables in quantities appropriate to mission volume.

- Ensuring redundancy by carrying backup aircraft for critical inspections.

Many large industrial sites already maintain inventory buffers for other tools and sensors. Adopting the same mindset for drone equipment can prevent costly downtime.

3. Evaluate Fleet Vulnerabilities and Dependencies

Every inspection program has a different level of reliance on DJI technology.

Some rely on Matrice aircraft for almost every flight. Others use DJI for rapid response but rely on specialized systems for complex or specific types of NDT work, like Flyability’s Elios 3 or Voliro’s Voliro T.

A quick self-assessment can help your team understand where its risks are concentrated:

- Which missions depend exclusively on DJI hardware?

- Which workflows use DJI-specific formats or cloud tools?

- How long can each airframe remain in service with current parts availability?

This kind of analysis can guide procurement decisions and help prioritize which drones need contingency planning first.

4. Start Evaluating Complementary Non-DJI Platforms

You don’t need to replace your DJI drones. But you may benefit from adding a secondary ecosystem for critical missions, specialized workflows, or long-term planning.

For example:

- Skydio’s X10 for automated outdoor inspections and obstacle-rich environments

- Flyability’s Elios 3 for indoor, GPS-denied confined-space inspections

- Voliro T for advanced NDT work (UT, EMAT, PEC, DFT, LPS)

Diversification helps reduce dependence on a single platform family and gives inspection teams options if procurement, parts, or support timelines become less predictable.

5. Communicate Early With Procurement, Maintenance, and Stakeholders

Inspection teams should coordinate with purchasing departments, reliability engineers, and site leadership to ensure everyone understands what has changed—and what has not.

When future availability is constrained, it’s easier to align budget, sourcing timelines, and internal expectations early than to scramble later after a failure, loss, or end-of-life event forces a replacement decision.

6. Document a 12–24 Month Continuity Plan

The best time to plan a transition is before you are forced into one.

A good continuity plan includes:

- Expected retirement dates for current DJI airframes

- Spare-parts needs through the next two inspection cycles

- Contingency options for high-priority missions

- Training needs if alternative platforms are introduced

With this level of preparation, industrial programs can continue operating smoothly while managing a market where new DJI models cannot enter through normal channels and long-term platform certainty has shifted.

Should Industrial Operators Buy DJI Drones Right Now?

For many industrial teams, the most practical question is also the simplest: Is now a good time to buy DJI drones?

The short answer is yes.

If DJI platforms are essential to your inspection workflows and you need predictable capacity for the next 12–24 months, it’s a good time to buy DJI drones while inventory is still available through authorized channels.

Current Availability Is Variable, and Inventory Is Finite

DJI stock in the U.S. has been inconsistent, and availability can change quickly.

Some DJI platforms remain available through authorized enterprise distributors like MFE, while other platforms see extended delays or disappear from the market as stock turns over.

If your organization relies on Matrice- or Mavic-series drones for core inspection work, buying that drones you need sooner rather than later can help protect your upcoming plans.

If You Need a Fleet Refresh in 2026, Waiting Can Introduce Real Risk

The practical risk is no longer uncertainty about whether a restriction will happen. It is the reality of procurement constraints over time.

Existing DJI models that already have FCC authorization can still be imported and sold, and existing U.S. inventory can still move through the market. But future DJI models do not have a normal path to U.S. approval, and supply across popular SKUs can tighten as inventory depletes or as sellers pull back due to compliance risk.

For industrial operators with multi-site inspection programs, that can create several challenges:

- Maintaining consistency across teams that rely on the same model and payloads

- Scaling inspections if additional aircraft are needed for shutdowns or major projects

- Replacing airframes with rising hours or aging batteries

If your team is already planning capital purchases for the next fiscal year, bringing those forward can be a reasonable way to reduce future disruption—especially if you are standardizing around a specific airframe, controller, or payload ecosystem.

What About Buying Used DJI Drones?

The used market remains active, but industrial operators should be cautious.

DJI enforces an account-binding policy, meaning: You must be able to unbind and rebind the drone to your own DJI account.

If the seller cannot complete the unbinding process, the drone may not activate, update, or operate correctly under your own credentials.

For operators with reliability requirements, internal cybersecurity policies, or strict documentation standards, buying used can introduce uncertainties around:

- Maintenance history

- Configuration drift

- Data-handling practices

Bottom Line: Buy DJI When It Protects Inspection Continuity

If DJI drones play a central role in your organization’s inspection workflows, buying the drones you need now is a good idea.

At the same time, DJI should be treated as a constrained ecosystem in the U.S. market.

For many industrial teams, the strongest approach is to stabilize the DJI fleet you already depend on while also building contingency options for specialized missions and long-term planning.

State and Local Restrictions: What Heavy-Industry Teams Need to Know

While the federal DJI restrictions get most of the attention, many industrial operators also work in jurisdictions where state or local rules affect drone procurement—especially when public agencies are involved.

These policies are typically aimed at government purchasing and use, not private-sector industrial operations.

But they can still matter for heavy-industry teams that collaborate with public partners, work under government-funded programs, or deliver data to agencies with strict equipment requirements.

Most Rules Target Government Procurement—But They Can Still Affect Industrial Work

In many cases, state and local restrictions apply to law enforcement, fire, DOT units, emergency management, and other public agencies. They generally do not make it illegal for private companies to fly DJI drones for industrial inspections, surveying, or other commercial work.

That said, these rules can affect industrial teams when:

- Your client, site owner, or partner is a public entity (or uses public funding) and is required to use approved/secure platforms.

- Joint operations involve government teams that can only fly specific drones (often tied to Blue UAS / Green UAS / NDAA-aligned procurement).

- Contract terms or site policies require “approved vendor” lists, supply-chain controls, or data-handling restrictions—regardless of what is legally allowed for private flight operations.

How to Interpret State and Local Restrictions Safely

State and local policies change frequently, and they’re not always written as “DJI bans.”

In practice, they often show up as:

- Procurement rules (what an agency can buy going forward)

- Use restrictions (what an agency can fly, even if it already owns the equipment)

- Approved-vendor frameworks (lists of allowed manufacturers or “countries of concern” language)

- Funding/eligibility constraints (rules tied to grants, homeland security funding, or critical-infrastructure programs)

If you operate across multiple states—or support customers nationwide—the safest approach is to treat this as a contract and procurement issue, not just a flight-operations issue.

Examples of States with Procurement or Use Restrictions

Rather than trying to maintain a complete 50-state list in this guide, here are a few examples that illustrate how these policies tend to work in practice (and why it’s important to verify requirements for your specific project and jurisdiction):

- Florida. Florida has implemented restrictions that affected public-agency drone procurement and use, driving many agencies to transition away from DJI and other covered vendors.

- Arkansas. Arkansas has enacted restrictions for public entities tied to “covered foreign” manufacturers, which includes common Chinese drone suppliers.

- Mississippi. Mississippi has enacted rules requiring certain state-purchased drones to meet U.S.-manufacturing / American-owned criteria, which can effectively exclude common foreign-made platforms from agency procurement.

States and Cities Considering Additional Restrictions

In other jurisdictions, proposals and policy discussions may be underway without becoming law—or may apply only to specific agencies, departments, or funding sources.

If you work with public partners (or serve regulated industries near critical infrastructure), it’s worth watching for:

- New procurement bills targeting “countries of concern,” critical components, or data-security requirements.

- Agency-level policy changes that restrict vendors even without a new state law.

- Local (city/county) procurement standards that can be stricter than state requirements.

What Industrial Teams Should Do

If your work intersects with government customers or government-funded projects, don’t guess. Treat compliance as part of project planning:

- Ask early whether the customer, site, or funding source requires NDAA-aligned platforms (or a vetted list like Blue UAS / Green UAS).

- Confirm whether the rule is about procurement or operations (buying vs. flying vs. both).

- Document the requirement in your scope of work so deliverables aren’t delayed late in the project.

- Use mixed-fleet planning when needed—keeping DJI where it’s allowed and practical, while maintaining compliant alternatives for restricted jobs.

This is also where MFE can help: we regularly support teams navigating procurement constraints, mixed-fleet strategy, and inspection-workflow

History of the DJI Ban: How We Got Here

To understand today’s DJI restrictions in the U.S., it helps to look at the broader policy arc that led here.

Concerns about foreign-made drones—especially those manufactured in China—have been circulating among federal agencies for years. Over time, a patchwork of advisories, grounding orders, procurement rules, and legislation shaped the landscape.

The result is the current reality: existing DJI models that already have the required FCC equipment authorization can still be sold and used, but the pipeline for new foreign-made drone models entering the U.S. market is now heavily constrained unless exemptions are granted.

Here is a timeline of key developments that explain how we got here.

2017–2020: The First Wave of Federal Concerns

- 2017. Federal agencies and military stakeholders begin raising cybersecurity concerns about Chinese-made drones. The U.S. Army stops using DJI drones in certain contexts as scrutiny grows.

- 2018. A third-party security assessment by Kivu Consulting (commissioned by DJI) reports no evidence of malicious data exfiltration in the reviewed configurations, while still recommending standard hardening practices for sensitive operations.

- 2019. DJI expands enterprise and government-focused security features, including offline/local data options, in response to growing procurement pressure and data-handling concerns.

- 2020. The U.S. Department of the Interior grounds much of its drone fleet amid cybersecurity concerns, highlighting how procurement and risk posture—not FAA flight legality—can drive operational decisions.

2021–2023: State Restrictions Expand and Federal Procurement Tightens

- 2021–2023. Multiple states adopt procurement restrictions affecting government agencies (police, fire, DOT, and other public entities). These policies vary widely by state but accelerate the shift toward “approved vendor” and “cleared list” approaches.

- December 2023. The American Security Drone Act of 2023 is signed into law as part of the FY2024 NDAA, creating procurement prohibitions that restrict certain federal purchasing pathways for covered unmanned aircraft systems tied to covered foreign entities.

2024: Legislation and Security Messaging Accelerate

- June 2024. DJI ends automatic flight-log syncing for U.S. users, emphasizing local control and offline operation options as part of its security posture for both enterprise and consumer operators.

- 2024. Multiple bills and policy proposals aimed at limiting Chinese-made drones continue moving through Congress, while agencies and critical-infrastructure stakeholders increase focus on supply-chain and data-security risk management.

- Late 2024. The final FY2025 NDAA includes an audit/review trigger tied to DJI and national-security review processes—setting the stage for a major inflection point in late 2025.

2025: The Trigger Moment and the Shift to a Post-Restriction Reality

- Early–mid 2025. DJI availability in the U.S. becomes inconsistent, driven by a combination of heightened regulatory scrutiny and supply-chain friction. Many organizations experience longer lead times, especially for popular enterprise models and accessories.

- June 2025. DJI publishes an updated security white paper outlining encryption, privacy controls, Local Data Mode, and enterprise data options intended to address procurement and cybersecurity concerns.

- December 2025. The policy landscape changes from “possible ban” to “active restriction.” The FCC issues a national-security determination and updates its Covered List posture in a way that blocks FCC equipment authorization for covered classes of new foreign-made drone models and certain related components—effectively preventing those new products from being legally imported, marketed, or sold in the U.S.

DJI Ban FAQ for Industrial Operators

Below are the most common questions industrial teams are asking about the DJI “ban” and what it means for inspections, fleet management, and procurement planning going into 2026.Is DJI banned in the U.S. right now?

No—there is not a blanket ban that makes DJI drones illegal to own or fly in the U.S. But there is a major restriction in place: new foreign-made drone models (including new DJI models) can no longer move through the normal FCC equipment authorization pathway needed for legal import, marketing, and sale. In practical terms, that means the U.S. market is now operating in a “closed pipeline” environment. Existing, previously authorized DJI models may still be available, but future DJI launches face a much higher barrier to entry.What exactly changed?

The key change is how new drone models enter the U.S. market. The restriction is enforced through the FCC equipment authorization process tied to national-security “Covered List” rules.- What’s restricted: New foreign-made drone models and certain covered RF components that do not already have FCC authorization.

- What’s not automatically restricted: DJI drones that already have FCC equipment authorization and are already in circulation.

Can I still fly my current DJI drones?

Yes. Existing DJI drones were not remotely disabled, and there has been no FAA action that grounds DJI drones already in service. If your team is operating DJI under Part 107 or other standard FAA rules, day-to-day flight operations are generally unchanged. The bigger issue is whether you can maintain and expand your fleet over time.Can I still buy DJI drones right now?

In many cases, yes—depending on availability. DJI models that were previously authorized can still appear through lawful channels while inventory lasts and supply remains intact. → See all the DJI drones currently available from MFE. For enterprise programs, the key is planning around lead times and continuity. If you rely on a specific DJI platform for a standardized workflow, it’s worth treating procurement as a capacity-planning decision (not a convenience purchase).What happens to repairs, batteries, and spare parts?

This is one of the biggest operational risks in a post-restriction environment. Even if a drone remains legal to fly, industrial teams can still run into friction if parts availability tightens or repair pathways slow down. Over time, organizations may encounter:- Longer lead times for repairs and warranty service

- Reduced availability of batteries and other consumables

- Greater reliance on secondary-market sourcing for components

Are DJI batteries and accessories affected too?

They can be. In practice, supply constraints often show up in consumables (especially batteries) before entire airframes disappear from circulation. If your inspection program depends on predictable uptime, treat batteries, props, and mission-critical accessories as part of your lifecycle planning—not as last-minute replenishment items.Is it safe to buy used DJI drones for industrial work?

Sometimes—but industrial teams should be cautious. DJI enforces an account-binding policy for many enterprise models. If the seller cannot (or will not) properly unbind the aircraft from their account, you may end up with a drone that cannot be activated, updated, or managed under your organization’s credentials. For enterprise operators, used purchases also introduce uncertainty around maintenance history, battery health, and internal chain-of-custody requirements. If reliability and traceability matter, buying used should be the exception—not the default plan.Does this restriction apply to private industrial operators, or only the government?

Both private and public operators are affected—just in different ways.- Operational legality: Private industrial operators can generally continue flying DJI drones already in service under normal FAA rules.

- Procurement reality: The restriction impacts the broader market’s ability to bring in and standardize on new foreign-made models going forward, which affects private buyers too.

How do state and local restrictions factor in?

Most state and local restrictions primarily target government procurement and agency operations—not private-sector industrial use. That said, they can still matter for heavy-industry teams when you work alongside public agencies, operate within public-sector procurement ecosystems, or deliver work that requires NDAA-aligned equipment. In those cases, planning for mixed fleets (DJI + compliant platforms) can reduce friction and keep projects moving.What if my client requires NDAA-compliant or “cleared list” drones?

If your client requires NDAA-compliant equipment, DJI is typically not the right path for that specific job. In those cases, operators usually look to platforms aligned with programs like Blue UAS and Green UAS, or to specialized industrial systems built for inspection environments. Several proven industrial alternatives are available through MFE, including:- Skydio X10 for autonomous outdoor inspections and obstacle-rich environments

- Flyability Elios 3 for confined-space inspections and indoor 3D mapping

- Voliro T for advanced NDT workflows on vertical infrastructure

Could the DJI situation change again?

Yes. The regulatory environment around foreign-made drones is still evolving, and future policy changes could tighten restrictions, introduce exemptions, or shift enforcement priorities. For industrial operators, the safest approach is to plan for continuity under uncertainty: stabilize the fleet you rely on today, avoid single-platform dependency for mission-critical programs, and build a procurement strategy that still works if the market becomes more constrained.What’s the smartest path forward for an inspection team?

For most heavy-industry programs, the best approach is not “replace DJI immediately” or “ignore the changes.” It’s to make your program resilient.- If DJI is core to your workflow: stabilize your fleet and plan around lifecycle support.

- If you need long-term procurement certainty: add at least one non-DJI platform for critical missions and future capacity.

- If you’re navigating compliance requirements: align platform choice to contract language and stakeholder expectations.