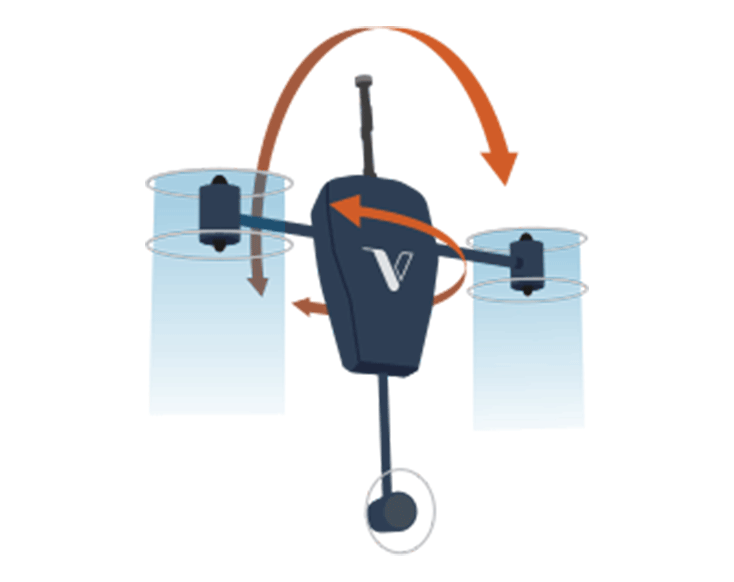

The Voliro T is a unique non-destructive testing (NDT) drone with omnidirectional flight capabilities and tiltable rotors, enabling precise and stable inspections in complex industrial environments.

Equipment Type: Drone

Request a Quote

The Voliro T drone’s unprecedented autonomy, omnidirectional functionality, and advanced physical interaction capabilities make it a revolutionary tool for performing ultrasonic testing (UT) in hard-to-reach environments.

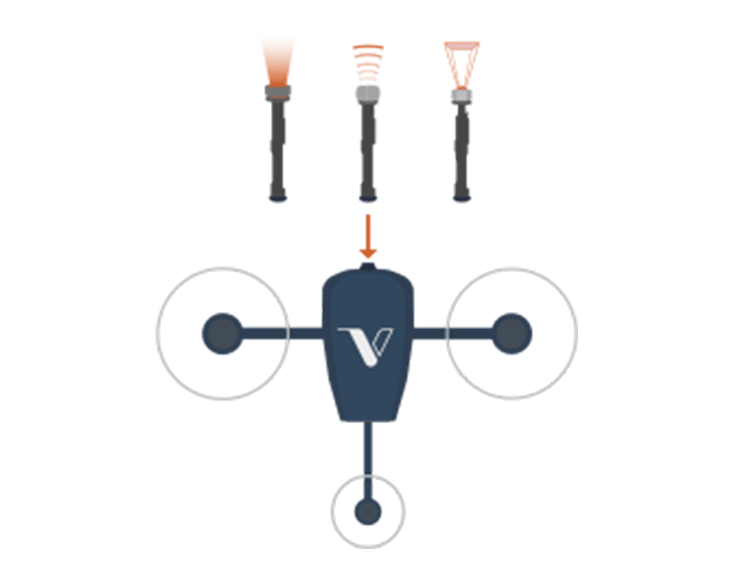

The Voliro T drone includes an NDT payload bundle featuring an electromagnetic acoustic transducer (EMAT), ultrasonic transducer, and a dry film thickness sensor for precise wall thickness measurements and surface corrosion detection.

Use a maximum force of 30N and apply various Nm of torque to structures. Engage in physical interaction with objects.

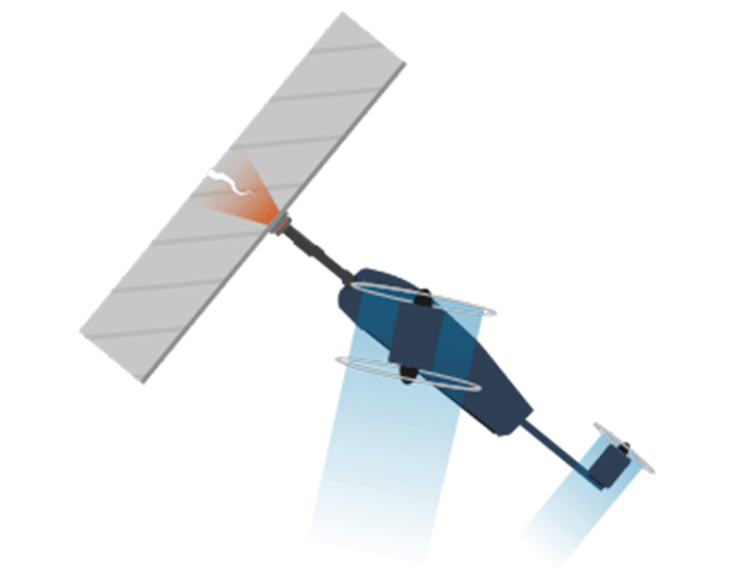

Experience unparalleled mobility with the Voliro T’s ability to tilt up to +-90°, enabling interaction in any orientation.

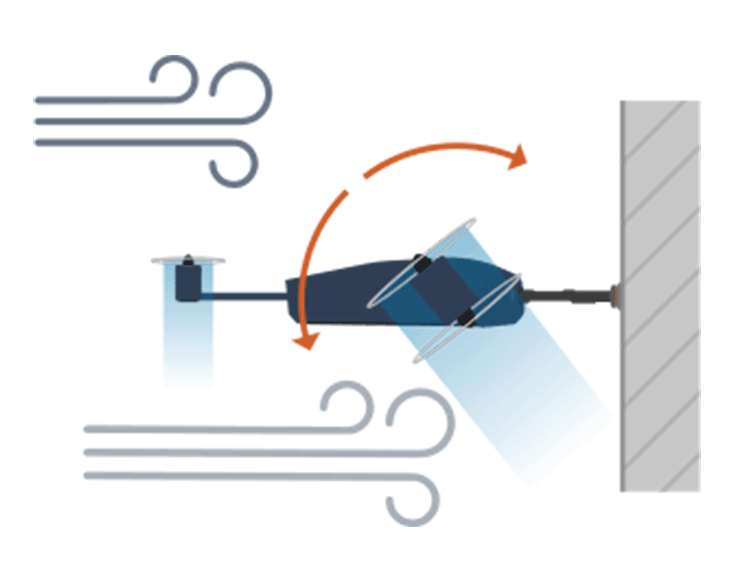

Implementing thrust-vectoring and 6DoF control ensures the necessary stability of teh Voliro T for dependable interaction even in challenging conditions.

With the its semi-autonomous flight modes and advanced pilot assistance, the Voliro T offers a safe and user-friendly flying experience, even in GPS-denied environments, allowing for close proximity flights near structures.

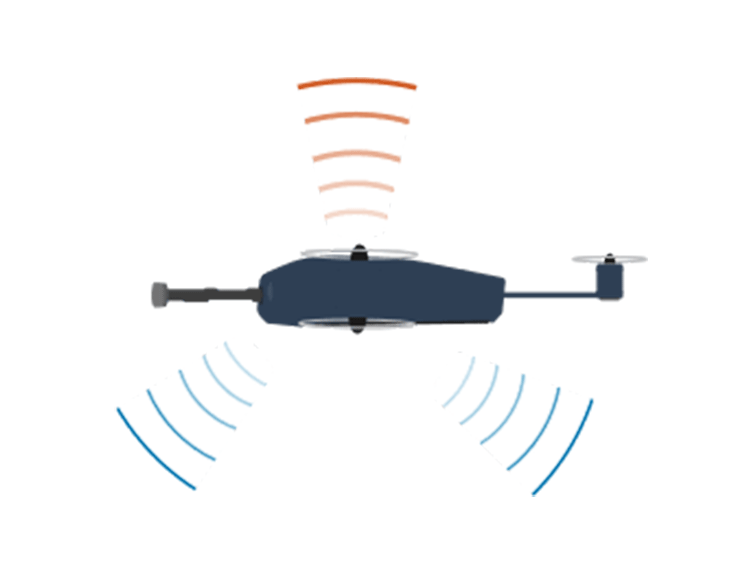

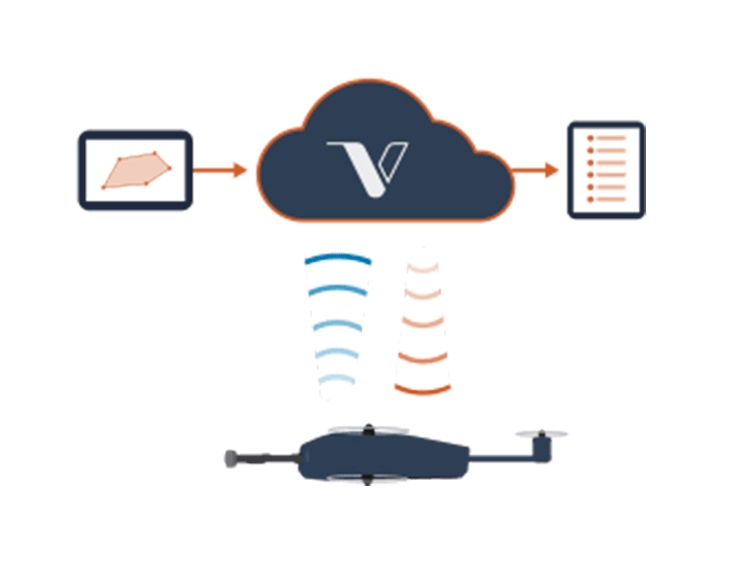

Designed to communicate with humans and machines, the Voliro T is equipped with open interfaces that enable seamless integration.

The Voliro T supports a range of custom payloads weighing up to 1kg and effective solutions for your challenges.

Additionally, the Voliro T is equipped with integrated sensors, including two 4k cameras and a depth camera.

Experience convenience and effortless portability with the Voliro T drone. Not only does the Voliro T come with a rugged, waterproof, crushproof transportation case, payload box, and accessories box, but the batteries are airline approved in accordance with the IATA TABLE 2.3.A, allowing you to pack them in your carry-on luggage conveniently for drone inspections.

Experience convenience and effortless portability with the Voliro T drone. Not only does the Voliro T come with a rugged, waterproof, crushproof transportation case, payload box, and accessories box, but the batteries are airline approved in accordance with the IATA TABLE 2.3.A, allowing you to pack them in your carry-on luggage conveniently for drone inspections.

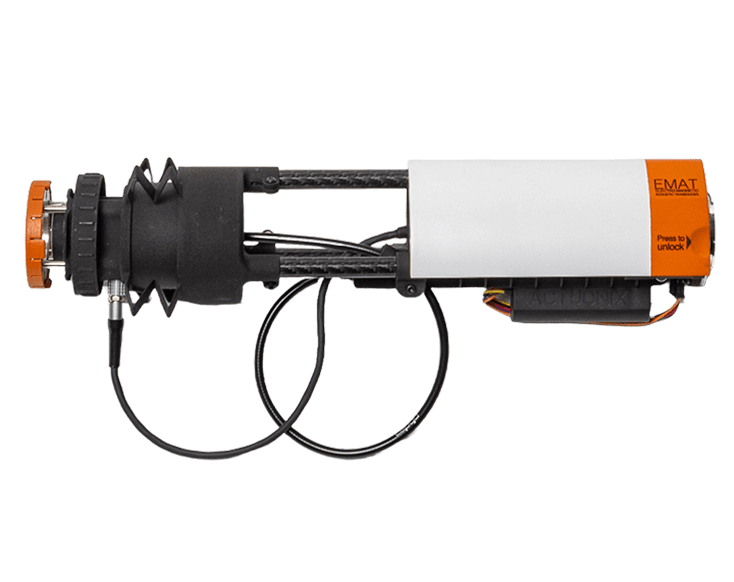

The EMAT is ideal for corroded and dirty surfaces, this sensor has a maximal lift-off of 4mm. It complies with ASTM E1816-18 standards and has a range of 2-150mm with an accuracy of 0.04mm.

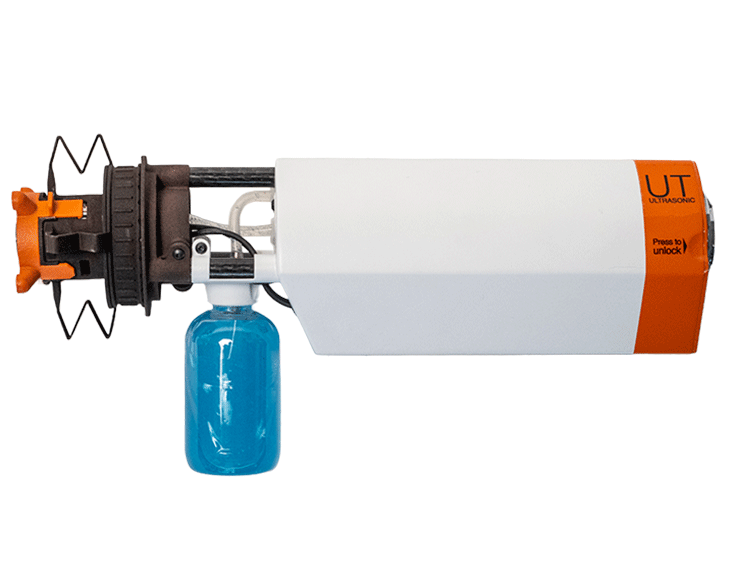

The ultrasonic transducer is compliant with EN 12668-1 and ISO 16831:2012.

This sensor offers echo-to-echo and pulsed echo test modes with live A-Scan. It has a thickness range of 4-150mm and a resolution of 0.02us (or 0.06mm at 5900m/s).

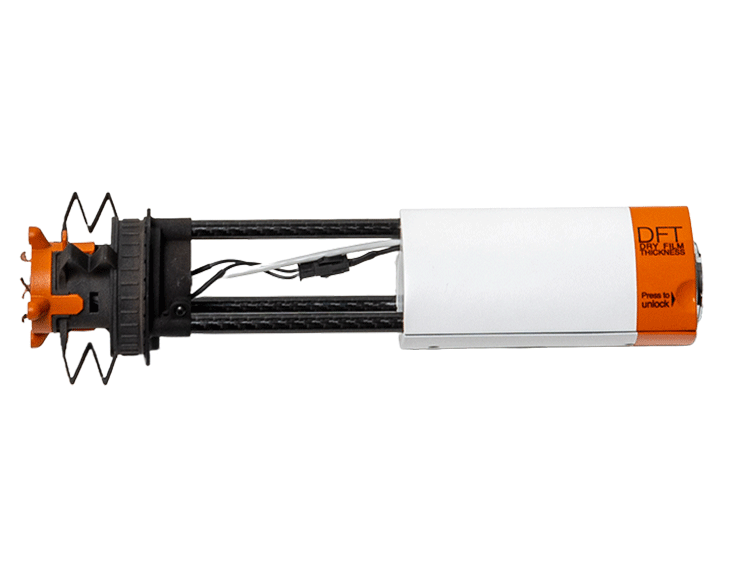

The DFT sensor measures the thickness of protective coatings. It uses magnetic induction and eddy current measurement modes, with a range of 0 to 1500um (or 700um).

The needle probe on the LPS tester ensures a reliable electrical connection with the lightning receptors, even in the presence of oxidation. The angular-compliant probe is designed to apply a consistent force of 30 N.

The PEC gauge is a non-destructive testing tool designed for detecting corrosion under insulation (CUI), coatings, and fireproofing on low-carbon steel structures. It enables accurate wall thickness measurements from 3 mm to 20 mm without direct metal contact, making it ideal for inspecting insulated, coated, or hard-to-access assets. With a 100 mm lift-off capability, it detects material loss without requiring insulation removal.

Enhance operational safety with the flammable gas sensor for the Voliro T, an integrated solution designed for real-time atmospheric monitoring during non-destructive testing inspections.

Built for demanding industrial environments, this sensor provides immediate visibility into flammable gas concentrations, empowering operators with critical information to avoid hazardous conditions during aerial inspections.

Now available as a complimentary upgrade to all Voliro T platform subscriptions, this sensor operates seamlessly alongside existing NDT payloads. It’s a powerful safety enhancement for teams conducting inspections in potentially explosive environments—no additional hardware changes or subscriptions required. The upgrade is available on request and integrates easily into your current workflow.

Key Highlights

This complimentary upgrade reflects Voliro’s commitment to advancing aerial inspection safety, helping teams mitigate risk without adding complexity to their operations.

Voliro T Technical Specifications

| Drone Type / Configuration | Multirotor / Omnidirectional Tri-Copter |

| Weight Batteries Included | 3.7 kg |

| Max Takeoff Weight | 6.0 kg |

| Max Payload Weight | 1,0 kg |

| Dimensions (LxBxH) | 78 x 78 x 34 cm without rotors, bumpers, and payload) 118 x 109 x 34 cm rotor tip to payload tip |

| Camera System | 4K 12MP Inspector Camera (Horizontal FoV 80°) 4K 12MP Pilot Camera (Horizontal FoV 140°) Frame rate: 30/60fps best GSD: 0.16mm/px Video Formats: H.265(.mp4) File Storage: microSD, 256GB |

| Downlink | Live Video Stream Inspector Camera: HD 30fps Live Video Stream Pilot Camera: HD 30fps Live Payload Data Stream |

| Power LEDs | max. 17'000 lumen adjustable through Remote Control |

| Sensing System | Depth Camera (VGA) 6 x LiDAR distance sensor 6 x Vision-based velocity sensor RTK GPS |

| Battery Type | LiPo (Hardcase, UN3481) |

| Battery Configuration | 2 x 6S batteries in parallel |

| Energy | 99Wh |

| Capacity | 2 x 4500 mAh |

| Weight | 1.3 kg per pair of batteries |

| Charging Cutoff Voltage | 25.2 V |

| Min Voltage | 21.6 V no load |

| Recommended Storage Voltage | 22.2 - 22.8 V |

| Recommended Charging Current | < 9 A or 1C |

| Charging Temperature | 10 - 30°C |

| Charging Time | < 90 min |

| Smart Battery | No, batteries must be treated and cared for accordingly |

| Transportation | Batteries airline approved according to IATA TABLE 2.3.A batteries have to be carried within carry-on baggage |

| Charge Type | Dual AC/DC LiPo charger with balancing function |

| Charger Input Voltage AC | 110 - 120V AC / 220 - 240 V AC (manual switch), 50 / 60Hz 9 - 32 V DC |

| Peak Output Power | 600 W |

| Flight Time | 10 - 14 min. mission and payload dependent |

| Flight Modes | Manual attitude is fully stabilized Altitude Position Interaction Assistant |

| Emergency Flight Modes | Intelligent auto-descent / position-hold on signal lost |

| Navigation Assistance | Outdoor GPS based: position, velocity, altitude Indoor GPS denied: height, velocity, altitude |

| Interaction Accuracy | ± 2 cm normal environment conditions |

| Max Horizontal Speed | 3 m/s in position flight mode 15 m/s in altitude and manual flight mode |

| Max Ascent / Descent Speed | 3 m/s in position and altitude flight mode |

| Pilot Tablet Included | Samsung Galaxy Tab S6 Lite |

| Tablet Charger | Data Link, 12v |

| Tablet Battery | 7040 mAh |

| Inspector Tablet Included | Same as Pilot Tablet |

| Remote Controller Mode | Mode 2 (Throttle and yaw on left stick) |

| Gimbal | Hall sensor M7 gimbal pinching thumbs compatible |

| Remote Controller Battery | 3600 mAh |

| Remote Controller Charger | Input 110 - 24v AC, Output 12.8v DC |

| GPS Antenna | Integrated active antenna |

| Tripod | Rollei Compact Traveler Star S1, 38.5 - 125cm |

| Battery | 3000 mAh |

| Charger | Input 110 - 240v AC, Output 12.8v DC |

| Compliance | ASTM E1816-18 |

| Test Mode | |

| Data Visibility | Live A-Scan displayed in the Voliro App |

| Operational Frequency | 3.5 - 4 MHz |

| Operation Temperature | -20 - 60 °C / -4 - 140 °F |

| Measurement Mode | Radially polarized shear waves |

| Resolution | 0.06 mm / 0.002 Inch |

| Thickness Range | 2 - 150 mm / 0.08 - 5.9 Inch |

| Max. Lift-off | 4 mm / .016 Inch |

| Min. Surface Diameter | 5 mm / .02 Inch |

| Compliance | EN 12668-1 and ISO 16831:2012 |

| Test Mode | |

| Data Visibility | Live A-Scan displayed in the Voliro App |

| Operational Frequency | 4 MHz |

| Operation Temperature | 0 - 60 °C / 32 - 140 °F |

| Measurement Mode | Compression wave |

| Resolution | 0.06 mm / 0.002 Inch |

| Thickness Range | 2 - 150 mm / 0.08 - 5.9 Inch |

| Elements | Dual-element |

| Couplant | Water-based gel |

| Compliance | EN 12668-1 and ISO 16831:2012 |

| Test Mode | |

| Data Visibility | Live A-Scan displayed in the Voliro App |

| Operational Frequency | 5 MHz |

| Operation Temperature | 0 - 260 °C / 32 - 500 °F |

| Measurement Mode | Compression wave |

| Resolution | 0.06 mm / 0.002 Inch |

| Thickness Range | 2 - 150 mm / 0.08 - 5.9 Inch |

| Echo to Echo | 2.5 - 50 mm / 0.1 - 2 Inch |

| Natural Focus Depth | 10mm / 0.394 Inch |

| Elements | Dual-element |

| Couplant | Extended temperature ultrasonic couplant |

| Compliance | EN ISO 1461, 2064, 2178, 2360, 2806, 3882, ASTM B 244, B 499, E 376 |

| Measurement Method | |

| Measurement Range |

| Manufacturer | Sixpec |

| Method | Pulsed Eddy Current, based on magnetic diffusing fields |

| Measurement Capabilities | Ferromagnetic steel through non-ferrous materials such as, not limited to: Coatings, corrosion product(scabs), Insulation (rock-wool, blankets, fireproofing), alluminum sheeting up 1mm, water / seawater, marine growth, fiber reinforced overlay |

| Data Visualization | Live A-scan, Percentage/Traffic light |

| Wall Thickness | 3 - 20 mm / 0.12 - 0.79 Inch depending on steel grade |

| Liftoff | 0 - 100 mm / 0 - 3.95 Inch |

| Jacket Surface Temperature | -40 °C to +100 °C / -40 °F to 212 °F |

| Footprint Diameter (area with 50% probe response) | ~50nn + 0.7 x liftoff / ~ 2 inch + 0.7 x Liftoff |

| Minimum Measurable Remaining Wall Thickness | 15% from nominal |

| Minimal Clearance to Ferromagnetic Structures / Edges | 15 cm / 5.91 Inch any direction |

| Smallest Detectable Defect Volume | ~15% of footprint volume |