Levatas Artificial Intelligence offers advanced AI-driven solutions for industrial automation and inspection.

By leveraging machine learning and computer vision, Levatas provides predictive maintenance, anomaly detection, and process optimization, enhancing operational efficiency and reducing downtime. Their AI solutions are tailored to meet the specific needs of various industrial sectors.

Equipment Type: AI Software

Request a Quote

Process data collected from RGB cameras, thermal, hyperspectral imaging systems, and X-ray. With the data collected from a quality image, Levatas Artificial Intelligence draws rich insights and decision-making capabilities through AI models.

Custom designed fully operational models for analog gauge reading, thermal anomaly and change detection.

Gauge reading models have the intelligence to adapt to and work in a broad range of real-world conditions and environments. Perspective warping takes environmental challenges into account, recognizing that one reading may not be as straightforward as the next. When presented with challenges like an obstructed view, condensation, or glare where a clear reading cannot be done, the model will proactively seek human-in-the-loop feedback from an expert over low accuracy results.

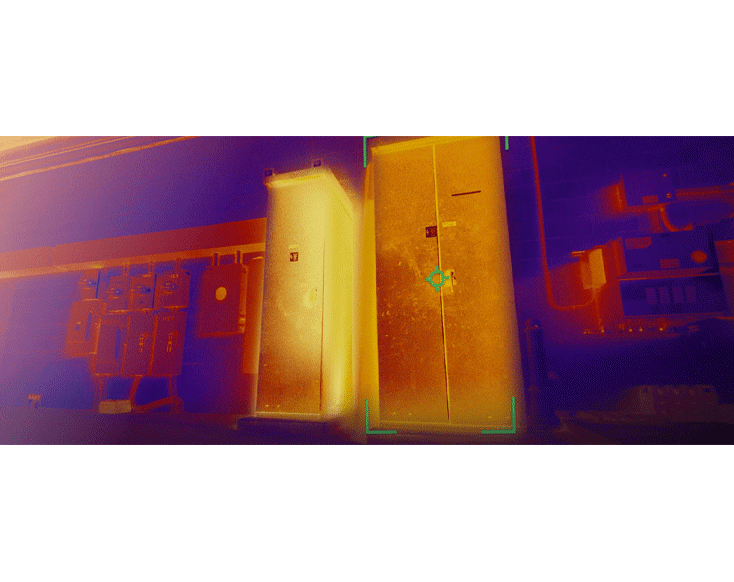

Thermal Anomaly Detection can be deployed and optimized using thermal sensor information, analytics, and machine learning to identify specific objects by their temperature against expected conditions.

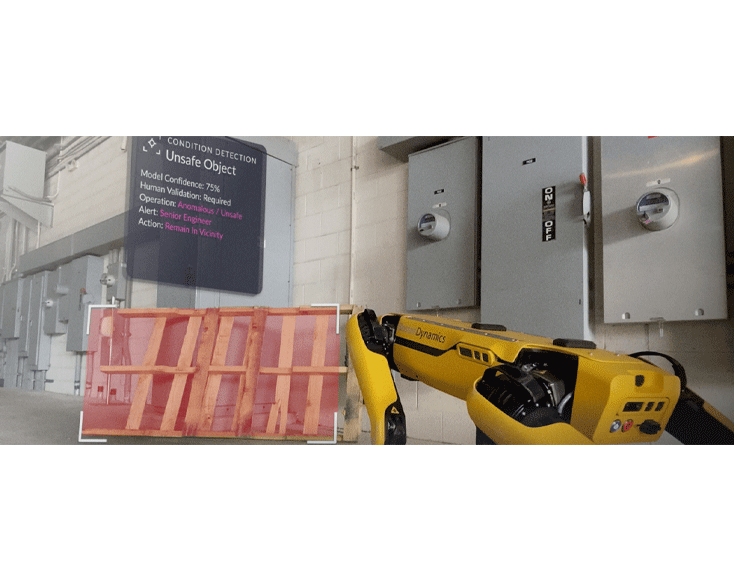

Detecting dangerous situations like standing water or unstable structures or calling attention to risky behavior patterns, AI can alert teams to threats and reduce risk quickly and effectively.

Detect when equipment at a facility shows signs of stress, overuse or anomalous behavior. Primarily used in manufacturing and assembly, the CV models can capture data using mobile or fixed cameras and flag issues to site supervisors, preventing costly assembly line shutdowns or injury.

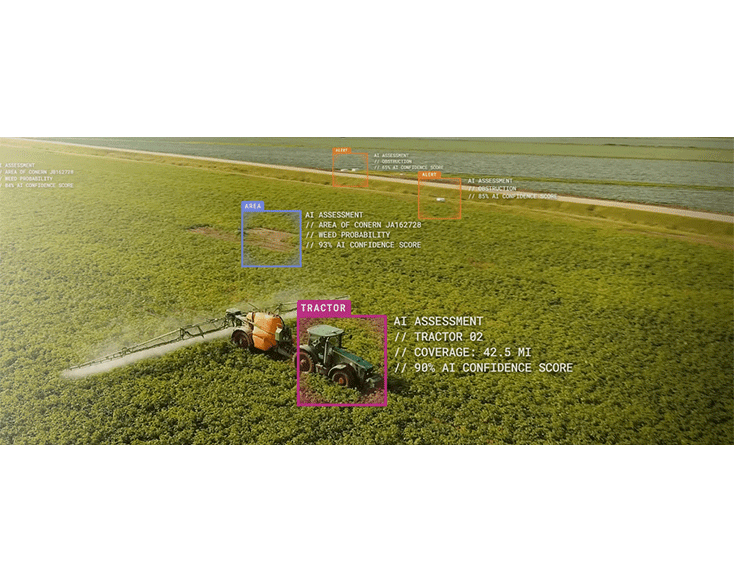

Streamline your aerial imaging process by running CV models that, once trained what to detect, can take a fraction of the time. Technologies use our human-in-the-loop approach that provides analysts areas of focus, getting to results faster and offering a chance to apply human skill to more important aspects of their projects.

© MFE Inspection Solutions Inc. 2024