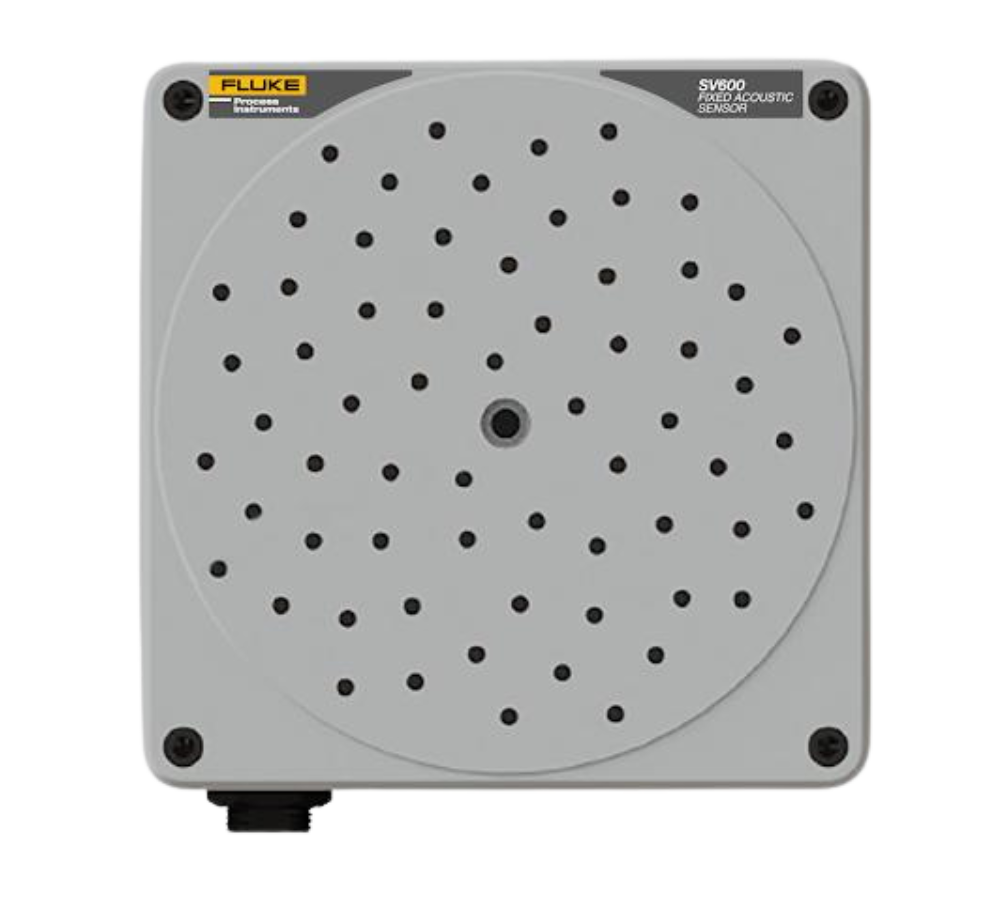

The Fluke SV600 is an advanced acoustic imaging camera designed to detect, visualize, and locate air and gas leaks or changes in sound signatures in real-time. Using SoundMap technology, it translates sounds into visual representations, providing insights into equipment health and enabling early intervention.

The SV600 can be integrated with Boston Dynamics’ Spot robot for automated inspections in hazardous environments, enhancing safety and operational efficiency.

Equipment Type: Acoustic Imaging

Request a Quote

Detect, visualize and locate air and gas leaks or changes in sound signatures across equipment in real-time before they become costly problems. By using an array of sophisticated sound sensors and the SoundMap technology, the SV600 translates sounds into visual representation providing facilities with further insights into product quality or safety concerns.

The SV600 can also be used as an acoustic imaging payload accessory for Boston Dynamics’ quadruped robot Spot. Use Spot to automate industrial inspections, monitor remote or hazardous environments and provide situational awareness in remote settings.

Spot can also be reconfigured for various use cases to increase efficiency and reduce safety risks. With the SV600 payload, Spot will now automate air and gas leak detection and identify mechanical sound signatures.

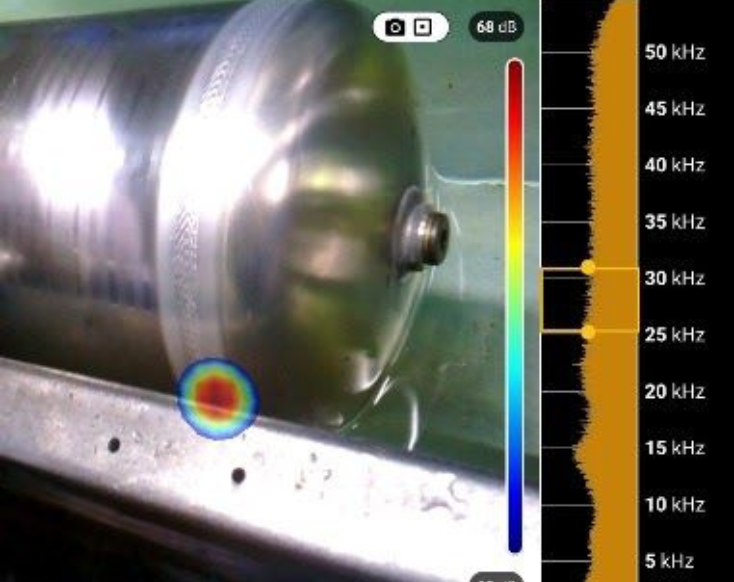

Identify partial discharge on high voltage lines, turbines and bus-bars that can lead to mechanical, thermal and chemical damage or even catastrophic arc flashing.

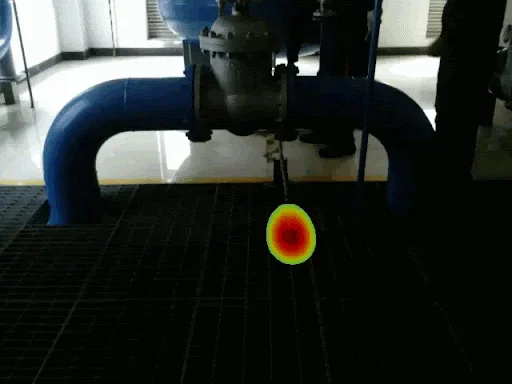

Identify and locate compressed air, gas, and vacuum leaks.

Mount the SV600 for continuous automated process monitoring, find defects and enable alarms.

Technical Specifications

| Ingress Protection | IP54 |

| Operating Temperatures | -20 °C to 50 °C (4 °F to 122 °F) |

| Weight | 0.85 kg (1.8lb) |

| Powered | PoE+ port 100-240V AC, max 37 W, IEEE 802.3 |

| Size (LxWxD) | 170 x 170 x 65mm (6.7 x 6.7 x 2.5 in) |

| Type | Type MEMS, Digital Bottom Port |

| SNR (A-weighted, at 1 kHz) | 64 dB for 94 dB SPL @ 1kHz |

| Sensitivity | -26 dBFS ± 1.5 dB, at 1 kHz, 94 dB SPL |

| Acoustic Overload Point | 120 dB SPL at 1 kHz, <10 % THD |

| Resolution Video | 720 x 1280 (still image) |

| Camera Resolution | 720 p at 30 fps |

| Field of View (FOV) | 65° +- 3° |

© MFE Inspection Solutions Inc. 2024