Guide

Pulsed Eddy Current Testing Explained: PEC for CUI/CUF Screening in the Field

Pulsed eddy current (PEC) is an electromagnetic NDT method used to screen for wall loss in metal, often without removing insulation, coatings, or fireproofing.

→ Jump to PEC solutions for CUI screening

In industrial settings, PEC is most commonly used to identify corrosion under insulation (CUI) and corrosion under fireproofing (CUF) on steel piping, tanks, vessels, and structural members.

Insulation removal can be expensive and time-consuming, requiring costly shutdowns. PEC testing can help reduce these costs, narrowing the scope to the areas that truly warrant follow-up.

This guide explains how PEC works, where it performs best, what its real-world limitations look like, and how to plan and document a PEC program so the results support defensible integrity decisions.

Use the menu to the right to jump around, or continue reading for the full guide.

Pulsed Eddy Current Solutions for CUI Screening

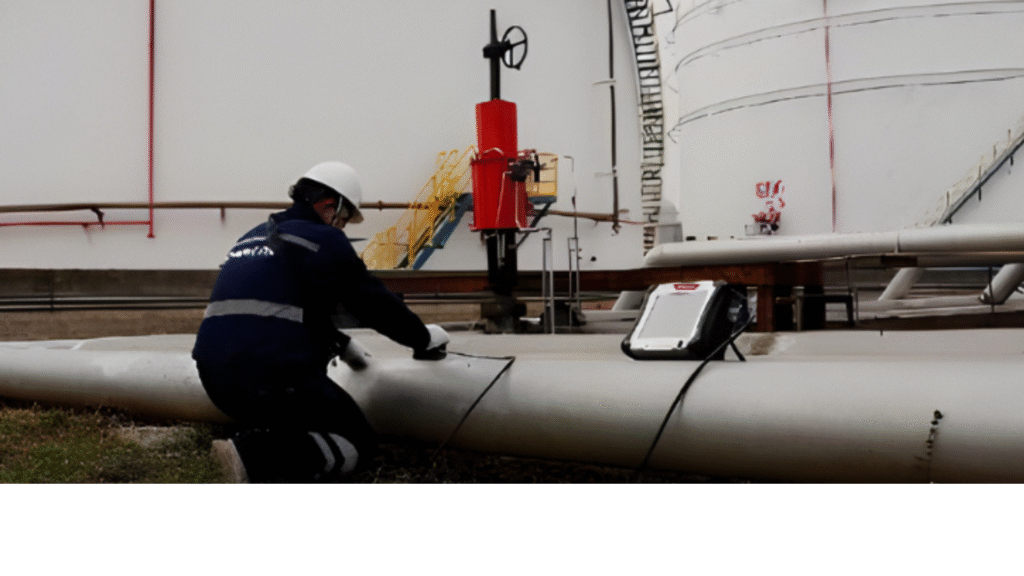

Teams most commonly deploy PEC from the ground with a handheld system.

But new drones like the Voliro T can now carry PEC sensors, allowing inspectors to do remote CUI screening for the first time ever.

Here are two PEC solutions MFE offers—one handheld and one drone-based.

MFE PulsePro

Use: Ground-based CUI screening

The MFE PulsePro is a field-ready pulsed eddy current system designed for non-intrusive wall-loss screening on insulated or coated steel assets.

It’s a practical fit when you need to screen a lot of locations efficiently, document results cleanly, and build a prioritized confirmation list without turning insulation removal into the main event.

Common fit:

- Pipe runs, vessels, and tank shells where insulation removal would create significant downtime or access costs

- Programs focused on broad screening coverage and repeatable location-based trending

- Teams that want a straightforward, ground-based workflow for triage and maintenance planning

Learn more about the MFE PulsePro.

Voliro T PEC

Use: Remote CUI screening at height

Voliro offers a drone-enabled PEC payload integrated with the Voliro T inspection drone, enabling PEC data collection on assets that are difficult, slow, or risky to access using traditional means.

The core value is access: when the best screening locations are elevated or require temporary infrastructure, an aerial workflow can reduce reliance on scaffolding, rope access, or lifts while still collecting contact-based inspection data.

Common uses:

- Insulated tanks, stacks, and other at-height assets where access drives most of the cost and schedule

- Screening programs where reducing work-at-height exposure is a priority

- Situations where you want to triage large vertical surfaces before committing to insulation removal

Learn more about PEC with the Voliro T.

Which Approach Is The Better Fit?

- Choose a ground-based PEC system when you have reasonable access and need efficient, repeatable screening across many locations.

- Choose drone-enabled PEC when access is the bottleneck—especially at height—so you can screen intelligently before investing in temporary infrastructure or insulation removal.

- Use both when your scope includes a mix of accessible pipework and hard-to-reach elevated assets, and you want one consistent screening-to-confirmation workflow.

What Is Pulsed Eddy Current (PEC)?

Pulsed eddy current (PEC) is a non-destructive testing method used to screen for wall loss in metal, often without removing insulation, coatings, or fireproofing.

In practice, PEC is commonly used to screen for corrosion under insulation (CUI) and corrosion under fireproofing (CUF) on steel assets like piping, tanks, vessels, and structural members.

What PEC Is Best For

PEC shines when your real problem isn’t “can we take a perfect point measurement,” but “how do we screen a big area efficiently and find where the risk actually is.”

It’s especially useful for corrosion under insulation (CUI) and corrosion under fireproofing (CUF) because it can often be performed without stripping large sections of insulation or fireproofing just to find out whether wall loss is present.

Pulsed eddy current inspection is a strong fit when you need to screen steel assets like:

- Piping runs and pipe supports where insulation removal would be slow or costly

- Tanks and vessels with coated or insulated sections

- Structural steel (legs, beams, skids) where access and prep drive most of the cost

Operationally, PEC is valuable because it helps teams reduce scope.

Instead of removing insulation everywhere “just in case,” you can use PEC to identify the locations most likely to warrant targeted follow-up with higher-resolution methods and repairs.

PEC is also commonly chosen when surface preparation is a constraint, whether due to limited shutdown windows, access limitations, or the practical reality that stripping and reinstating insulation is often the most expensive part of the job.

Pulsed Eddy Current vs Eddy Current Inspection

Pulsed eddy current and conventional eddy current methods are closely related.

They’re both electromagnetic NDT techniques that induce currents in metal and analyze the response.

The practical difference is how the energy is applied and what kinds of inspection problems each approach is typically optimized for.

| Topic | Pulsed Eddy Current (PEC) | Conventional Eddy Current |

|---|---|---|

| Primary job | Screening for wall loss and thickness changes over an area | Detecting and characterizing near-surface conditions and indications |

| How it’s applied | A short pulse is sent and the time-based decay response is analyzed | A continuous or swept signal is used and the response is analyzed during excitation |

| Typical strength | Useful when you need screening through barriers like insulation, coatings, or fireproofing (with practical limits) | Useful when you can couple near the surface and need sensitivity to smaller, localized conditions |

| What the output often represents | Often an average thickness estimate over a probe footprint, used for triage | Often an indication-focused response used for characterization of localized features |

| Common fit | CUI/CUF screening on insulated steel assets | Eddy current inspection for localized near-surface evaluation where access and surface proximity are feasible |

The easiest way to choose is to start from the problem:

- Big area = PEC. If you need broad screening for wall loss with minimal removal and disruption, PEC is often the better starting point.

- Smaller areas = EC. If you need sensitivity to localized near-surface conditions and can work close to the material surface, conventional eddy current methods are often a better fit.

How Pulsed Eddy Current Testing Works

At a high level, pulsed eddy current testing is about sending energy into metal and watching how the metal responds over time.

Here’s how it works.

1. Probe Delivers a Short Electromagnetic Pulse

That pulse induces circulating electrical currents in the metal (often called eddy currents).

2. Induced Currents Spread and Fade

Those induced currents don’t stay the same, but instead spread and fade.

As the currents diffuse deeper and decay, the instrument records how quickly the response drops over a series of time “gates.” You can think of this as a decay curve: a time-based signature of how the metal is behaving.

3. Wall Thickness Changes Decay Behavior

All else equal, thinner or more degraded metal tends to produce a different decay pattern than thicker metal.

The PEC instrument uses calibration and signal processing to convert that time-based response into an estimated remaining wall.

4. PEC Often Reads as an Average—Not a Pintpoint

The probe energizes an area, not a single microscopic point.

That means the result commonly reflects an average thickness over the probe’s effective footprint.

Localized features like tight pitting or sharp transitions can be “smoothed out” in the number you see, which is one reason PEC is often used for screening and triage.

5) How PEC Works through Insulation

PEC doesn’t need direct contact with bare metal the way some methods do, but there is still a standoff between the probe and the steel (often called lift-off).

More lift-off generally reduces signal strength and can affect confidence in the estimate, which is why insulation thickness, jackets, and surface layers matter when you’re planning an inspection.

Planning a PEC Inspection

A good PEC program starts with planning.

The method is fast, but only when you choose test locations intelligently and capture enough context for the results to be usable later.

1) Define the screening goal

- Are you trying to triage a large system for follow-up, validate a suspected CUI zone, or establish a baseline for future trending?

- Clarity here determines how dense your coverage needs to be and how you’ll handle confirmations.

2) Choose locations that reflect how CUI/CUF actually happens

- Start with high-likelihood areas: water traps, low points, damaged jacketing, penetrations, supports, clamps, and interfaces where moisture collects.

- Include a few “expected good” baseline locations on the same asset so the team can sanity-check signals and reduce false alarms.

3) Set a spacing approach that matches risk and consequence

- Use wider spacing for broad triage, tighter spacing where risk is higher or where decisions will be made from the screening results.

- When in doubt, prioritize consistency over perfection: repeatable, documented coverage beats ad hoc point picking.

4) Plan for lift-off realities before you get to the field

- Insulation thickness, jacketing, coatings, and fireproofing create standoff between the probe and the steel.

- Document what you’re testing through (type and condition), and flag locations where lift-off is unusually high or inconsistent.

5) Think about geometry and access (not just “can we reach it?”)

- Avoid placing readings too close to edges, seams, or abrupt geometry changes unless the procedure explicitly accounts for it.

- Confirm you can place the probe consistently at each location—repeatable placement is a major driver of reliable screening.

6) Decide what “good documentation” means up front

- Record location identifiers that can be found again: line/asset ID, stationing, orientation (clock position), and nearby physical references.

- Take a photo of each location (or each zone) with markings visible, and note insulation/jacketing condition.

- Capture any context that affects interpretation: temperature, access constraints, unusual surface layers, or known repairs.

7) Build the confirmation path into the plan

- Define how suspect locations will be confirmed (commonly UT) and who owns that decision.

- For pulsed eddy current inspection used as screening, the cleanest workflow is: screen broadly, confirm selectively, then document the decision trail.

Writing a Useful PEC Report

PEC results are most defensible when you treat them as screening evidence: useful for triage, stronger when supported by context, and most actionable when they produce a clear confirmation plan.

How to interpret PEC results in a screening mindset

- Compare like-for-like. Give more weight to comparisons within the same asset, similar geometry, and similar insulation/jacketing conditions.

- Use baseline locations. “Expected good” readings on the same system help you recognize what normal looks like and reduce overreaction to noise.

- Look for patterns, not isolated numbers. Clusters of suspect readings in a moisture-prone zone are typically more meaningful than a single outlier with no supporting context.

- Separate signal quality from wall-loss suspicion. Flag locations where lift-off, access, or inconsistent placement likely reduced confidence—even if the thickness estimate looks benign or alarming.

Turn screening into triage

- Group nearby suspect points into “zones” that can be confirmed efficiently (one insulation removal activity can address multiple readings).

- Prioritize zones by consequence: critical lines, safety impact, leak likelihood, and operational sensitivity.

- Make the handoff clear: which locations require confirmation, which are monitor-only, and which are considered normal for now.

What a useful PEC report includes

- Asset context. Asset/line ID, service, location, and the screening objective.

- Method notes. Pulled from pulsed eddy current screening reality: what you tested through (insulation type/thickness if known, jacketing condition, coatings/fireproofing) and any access constraints.

- Location traceability. Unique location IDs, stationing/orientation (clock position), and markings that allow the same spot to be found again.

- Readings with context. The thickness estimate alongside notes on signal quality, lift-off concerns, geometry proximity, and anything unusual.

- Photos. Clear images of each location or zone with markings visible.

- Recommendations. A prioritized confirmation list (commonly UT), including the reason each location is flagged and what decision it supports.

What PEC Can and Can’t Tell You

PEC is most valuable when you treat it as a way to sort risk, not as the final word on remaining wall.

In many real-world use cases, PEC outputs an estimated thickness that reflects an average over the probe’s effective footprint. That’s a feature for screening: it helps you quickly identify areas that are likely thinner than expected. But it also means PEC can under-represent tight, highly localized damage if that damage occupies only a small portion of the energized area.

What PEC is well-suited to support:

- Finding areas that merit follow-up during CUI/CUF screening

- Comparing suspect locations against “normal” baseline areas on the same asset

- Building a prioritized confirmation list so higher-resolution methods are used where they matter most

Where PEC is not a good “final decision” tool by itself:

- When you need a precise point thickness at a specific location

- When the decision has high consequence (repair vs run, fitness-for-service inputs, critical near-term go/no-go calls)

- When you suspect very localized corrosion mechanisms that could be missed by averaging

A practical way to use PEC is to let it drive the workflow: screen broadly, document clearly, and then confirm the locations that drive decisions.

Ultrasonic thickness (UT) is a common confirmation path because it can provide more localized measurements once you’ve narrowed the scope to the right spots.

6 Pulsed Eddy Current Limitations to Know

PEC is a powerful screening method, but it’s easy to misuse if you assume it behaves like a pinpoint thickness gauge.

Understanding limitations up front is how you get results that lead to good decisions.

Here are six of its main limitations to be aware of:

1. Averaging Over the Probe Footprint

- Limitation: PEC often reports an average thickness over the energized area, not the thinnest point within it. This means that tight, localized wall loss can be “smoothed out” in the number you see.

- Practical move: Interpret patterns and clusters, not isolated readings; confirm suspect zones with a localized method.

2. Localized Pitting and Very Small Damage

- Limitation: Because of averaging, PEC may not reflect the severity of small, deep pits or very localized corrosion mechanisms.

- Practical move: If pitting is suspected, treat PEC as a finder and plan confirmation accordingly.

3. Edges and Abrupt Geometry Changes

- Limitation: Readings near edges, seams, nozzles, supports, and abrupt geometry changes can behave differently because the induced current paths are disrupted.

- Practical move: Keep locations away from edges where possible; document geometry proximity when you can’t.

4. Lift-Off Variability

- Limitation: Insulation thickness, jackets, coatings, and fireproofing create standoff between the probe and steel, affecting signal strength and confidence.

- Practical move: record what you tested through, note inconsistent or high lift-off, and avoid comparing readings collected through very different layers as if they’re equivalent.

5. Surface Layers and Field Conditions

- Limitation: Real-world conditions—coating systems, jacketing condition, moisture, access constraints, and placement repeatability—can all influence signal quality.

- Practical move: prioritize consistent placement and thorough documentation; use baseline locations to validate the setup.

6. Near-Side vs. Far-Side Interpretation Limits

- Limitation: PEC is generally used to infer overall wall condition rather than precisely locating where through-wall loss is occurring within the thickness.

- Practical move: use PEC to identify suspect areas, then use confirmation methods to localize and size the damage when needed.

Pulsed Eddy Current Training and Qualifications

PEC is straightforward to operate, but reliable results require consistent technique and disciplined interpretation. Most PEC problems in the field aren’t “the tool didn’t work”—they’re setup, placement, or reporting issues that make the data hard to trust later.

Strong PEC testing competency usually includes:

- Setup discipline. Using the same procedure each time for checks, references, and instrument settings so results are comparable.

- Repeatable probe placement. Consistent contact and positioning, with awareness of how small placement changes can affect screening outputs.

- Lift-off awareness. Knowing how insulation thickness, jacketing, coatings, and fireproofing affect signal confidence, and documenting those conditions instead of ignoring them.

- Geometry judgment. Recognizing when edges, seams, supports, and abrupt geometry changes may influence readings and adjusting location selection accordingly.

- Traceable documentation. Marking and recording locations so results can be re-found, re-tested, confirmed, and defended.

Equally important is interpretation discipline. PEC is commonly used for screening and triage, which means the team needs a clear rule for when screening results trigger confirmation with a more localized method and who owns that decision.

Many organizations improve quality by separating roles:

- Field operator collects consistent readings and records context (layers, access constraints, geometry notes, photos).

- Reviewer/analyst or QA lead checks coverage, looks for patterns, validates baselines, and produces the prioritized confirmation list.

When PEC results will drive high-consequence decisions, a second set of eyes—either internal QA or an experienced reviewer—often pays for itself by catching preventable errors before they turn into rework or poor calls.

Pulsed Eddy Current FAQ

Here are answers to some of the most commonly asked questions about Pulsed Eddy Current (PEC) and how it’s used in NDT.

What Is Pulsed Eddy Current (PEC)?

PEC is an electromagnetic NDT method used to screen for wall loss in metal by sending a pulse into the material and analyzing the time-based response. It’s commonly used to triage corrosion risk on assets where direct access to bare metal is inconvenient.

What Is Pulsed Eddy Current Testing Used For?

Pulsed eddy current testing is most often used for screening corrosion under insulation (CUI) and corrosion under fireproofing (CUF) on steel piping, tanks, vessels, and structural members. It helps teams identify where follow-up inspection is most likely to be needed.

Can PEC Test Through Insulation?

PEC can often screen through insulation, coatings, or fireproofing because it doesn’t require direct contact with bare metal in the same way some methods do. In practice, insulation thickness, jacketing condition, and other layers still matter because they affect lift-off and confidence.

How Accurate Is PEC?

PEC is best thought of as a screening method rather than a pinpoint thickness gauge. In many setups it reports an average thickness over a probe footprint, which is useful for triage but can miss or under-represent very localized damage.

Does PEC Detect Pitting?

PEC can indicate that an area may be degraded, but tight pitting can be challenging because localized damage may be averaged within the probe footprint. If pitting is suspected, PEC is often used to find suspect zones that should be confirmed with a localized method.

Is PEC A Replacement For Ultrasonic Thickness (UT)?

Not usually. PEC is commonly used to screen and prioritize where UT (or other localized methods) should be applied, especially when insulation removal is costly or disruptive.

What Does “PEC Unit” Mean?

A PEC unit typically refers to the instrument plus the probe(s) and software used to collect and interpret readings. Probe choice and placement consistency have a major impact on what the results represent.

What Is PEC Array (PECA)?

PEC array (PECA) is a higher-coverage approach that collects denser data across an area compared to isolated spot readings. It’s often used when systematic coverage and repeatable documentation matter as much as speed.

What’s The Difference Between PEC And Eddy Current Inspection?

Both are electromagnetic methods, but they’re commonly optimized for different jobs. PEC is frequently used for wall-loss screening (often through layers), while eddy current inspection is often used when near-surface sensitivity and localized evaluation are the priority.

What Is A PEC Unit?

A PEC unit typically refers to the full pulsed eddy current testing setup used in the field—not just a handheld device. It usually includes the instrument that generates the pulse and records the response, one or more probes that define the effective test area, and software for viewing and logging results. Probe selection and placement matter because the probe footprint influences what the reading represents. In many cases, the value reflects an average thickness over that energized area rather than a pinpoint measurement, which is why PEC is commonly used as a screening tool.

What Is PEC Array (PECA)?

PEC array (often abbreviated PECA) is a higher-coverage approach to pulsed eddy current inspection that captures denser data across an area instead of relying on isolated spot readings. The advantage is coverage and repeatability. Array-based workflows are often used when you need more systematic documentation of what was screened, clearer coverage mapping, and a stronger basis for prioritizing confirmation work on large insulated assets.

When Should PEC Results Be Confirmed?

When results will drive high-consequence decisions, when localized corrosion is suspected, or when field conditions reduce confidence (high/variable lift-off, difficult geometry, inconsistent placement). A clear confirmation plan is one of the best ways to make PEC defensible.