Guide

Ground Penetrating Radar (GPR): An In-Depth Guide [New for 2025]

Ground Penetrating Radar (GPR) is an NDT method that uses electromagnetic waves—also called radar pulses—to penetrate and reflect off subsurface structures and materials in order to find defects or flaws.

Alternate phrases for ground penetrating radar include:

- Subsurface radar inspection

- Georadar scanning

- Ground radar detection

- Ground-penetrating survey

- GPR scanning

- Ground radar imaging

Ground penetrating radar is particularly effective for identifying and mapping subsurface structures and anomalies during inspections, including:

- Buried utilities. Detects and maps the location of underground utilities such as pipes, cables, and conduits, helping to avoid damage during construction and excavation activities.

- Subsurface voids. Identifies voids, sinkholes, and other subsurface cavities that could pose a risk to structural stability and safety.

- Archaeological features. Maps archaeological sites and artifacts without disturbing the soil, providing valuable information for excavation planning and preservation.

- Concrete integrity. Evaluates the internal structure of concrete slabs, locating rebar, post-tension cables, and voids to assess the condition and ensure the safety of structures.

- Soil layers. Detects variations in soil composition and stratigraphy, aiding in geological studies and environmental assessments.

- Contaminant detection. Identifies areas of soil and groundwater contamination by mapping subsurface anomalies and changes in material properties.

Some of the top industries that use GPR include construction, archaeology, environmental studies, and utility locating, where understanding subsurface conditions is crucial for planning and safety.

This article provides a comprehensive overview of ground penetrating radar, exploring the tools and techniques used, the various types of GPR methods, the scenarios where this method is most beneficial, and the applications of GPR across the main industries that use it.

Have a specific topic in mind? Use the menu to the right to jump around within this guide.

What Is Ground Penetrating Radar (GPR)?

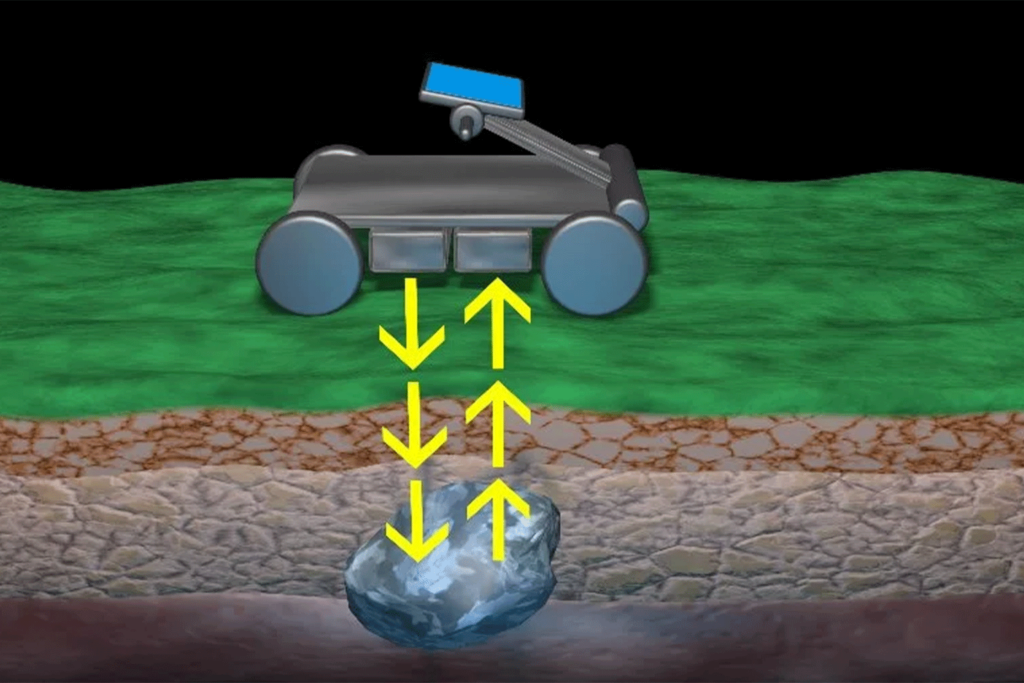

Ground Penetrating Radar (GPR) is a geophysical method for non-destructive testing that uses radar pulses to create images of the subsurface.

This technique involves transmitting high-frequency radio waves into the ground and measuring the reflected signals from subsurface structures.

By analyzing these reflections, GPR can provide detailed information about the composition, depth, and condition of subsurface features.

Principles of Ground Penetrating Radar

The fundamental principle of GPR is based on the transmission and reflection of radar waves.

Here are the key steps involved in GPR:

1. Signal Transmission

A GPR system consists of a transmitting antenna that emits short pulses of high-frequency radio waves into the ground.

2. Signal Reflection

When these radio waves encounter different subsurface materials or structures, they are reflected back to the surface. The amount of reflection depends on the dielectric properties of the materials.

3. Signal Reception

A receiving antenna captures the reflected signals, which are then recorded and processed by the GPR system.

4. Data Analysis

The recorded signals are analyzed to create a cross-sectional image (radargram) of the subsurface. This image shows the location and depth of subsurface features based on the time it takes for the signals to return.

Advantages of Ground Penetrating Radar

- Non-destructive. GPR is a non-invasive method that does not require drilling or excavation, preserving the integrity of the site while providing detailed subsurface information.

- High resolution. GPR can produce high-resolution images, allowing for the detection of small and shallow subsurface features.

- Versatility. The technique can be used on various terrains and materials, including soil, rock, concrete, and ice, making it suitable for a wide range of applications.

- Real-time results. GPR provides immediate feedback, allowing for real-time decision-making during surveys.

Limitations of Ground Penetrating Radar

- Depth penetration. The depth of penetration is limited by the frequency of the radar waves and the conductivity of the subsurface materials. Higher frequencies provide better resolution but shallower penetration, while lower frequencies penetrate deeper but with lower resolution.

- Signal interference. GPR signals can be affected by various factors such as soil moisture, temperature, and the presence of metallic objects, which can create noise and reduce data quality.

- Data interpretation. Interpreting GPR data requires expertise and experience, as the radargrams can be complex and challenging to analyze accurately.

Ground Penetrating Radar Tools

Ground Penetrating Radar (GPR) relies on a variety of specialized tools and equipment designed to transmit and receive radar signals, process data, and generate subsurface images.

Each tool serves a specific purpose, from transmitting and receiving radar signals to processing and mapping data, ensuring that GPR remains a reliable and effective method for non-destructive testing.

Below is a detailed overview of the primary tools used in GPR.

1. GPR Systems

I. Handheld GPR Units are portable devices used for quick and easy subsurface scanning.

- How they work. Handheld units contain both the transmitting and receiving antennas and are typically used for small-scale surveys or spot checks.

- Applications. Ideal for utility locating, concrete inspection, and archaeological surveys.

II. Cart-based GPR Systems are larger, wheeled units that are pushed or pulled across the survey area.

- How they work. These systems provide more stable data collection and can cover larger areas efficiently.

- Applications. Commonly used in construction, environmental studies, and large-scale utility mapping.

III. Vehicle-Mounted GPR Systems are mounted on vehicles for surveying extensive areas.

- How they work. These systems allow for rapid data collection over large areas by driving the vehicle across the survey site.

- Applications. Suitable for road and bridge inspections, large construction projects, and geological surveys.

2. Antennas

I. High-Frequency Antennas are antennas that operate at frequencies typically above 500 MHz.

- How they work. Higher frequencies provide better resolution but shallower penetration.

- Applications. Ideal for detecting small, shallow features in concrete, asphalt, and other construction materials.

II. Low-Frequency Antennas are antennas that operate at frequencies below 500 MHz.

- How they work. Lower frequencies penetrate deeper into the ground but provide lower resolution.

- Applications. Used for geological surveys, deep utility mapping, and environmental studies.

III. Multi-Frequency Antennas are antennas capable of operating at multiple frequencies.

- How they work. These antennas offer a balance between depth penetration and resolution, making them versatile for various applications.

- Applications. Suitable for diverse tasks ranging from shallow utility detection to deeper geological investigations.

3. Data Processing Software

I. Real-Time Data Processing Software is software that processes GPR data as it is collected.

- How they work. This software provides immediate feedback, allowing for real-time analysis and decision-making during surveys.

- Applications. Used in field surveys where quick assessment and adjustments are needed.

II. Post-Processing Software is software used to analyze and interpret GPR data after it has been collected.

- How it works. This software enhances and filters the data, generating detailed subsurface images and reports.

- Applications. Essential for in-depth analysis and detailed reporting in construction, archaeology, and environmental studies.

4. Positioning and Mapping Tools

I. Global Positioning System (GPS) Units are devices used to record the geographic location of GPR data points.

- How they work. GPS units integrate with GPR systems to provide accurate location data for each survey point.

- Applications. Crucial for mapping and correlating subsurface data with surface features, particularly in large-scale surveys.

II. Total Stations are precision instruments used for surveying and mapping.

- How they work. Total stations measure distances and angles, providing highly accurate position data for GPR surveys.

- Applications. Used in conjunction with GPR for precise mapping in construction and civil engineering projects.

Types of Ground Penetrating Radar

Ground Penetrating Radar (GPR) encompasses several techniques, each tailored to specific inspection needs and applications.

These methods vary based on the frequency of the radar waves and the configuration of the equipment.

Here are the main types of GPR:

1. Single-Frequency GPR

A method that uses a single frequency for both transmitting and receiving radar signals.

- How it works. The GPR system emits radar waves at a fixed frequency and captures the reflected signals to create subsurface images.

- Applications. Suitable for specific tasks where the depth and resolution requirements are well-defined, such as utility locating and concrete inspection.

2. Multi-Frequency GPR

A technique that uses multiple frequencies to transmit and receive radar signals.

- How it works. The GPR system alternates between different frequencies, providing a balance between depth penetration and resolution.

- Applications. Ideal for complex surveys requiring detailed imaging at various depths, such as archaeological studies and environmental investigations.

3. Air-Launched GPR

A method where the GPR antenna is positioned above the ground surface, typically on a vehicle or drone.

- How it works. The antenna emits radar waves that penetrate the ground from above, allowing for rapid data collection over large areas.

- Applications. Used for large-scale surveys such as road and bridge inspections, agricultural studies, and military applications.

4. Ground-Coupled GPR

A technique where the GPR antenna is in direct contact with the ground surface.

- How it works. The antenna emits radar waves that penetrate the ground directly, providing high-resolution images of shallow subsurface features.

- Applications. Suitable for detailed inspections of concrete, asphalt, and other construction materials, as well as archaeological investigations.

5. Step-Frequency GPR

A method that uses a range of frequencies to build a detailed subsurface image.

- How it works. The GPR system emits radar waves at incrementally increasing frequencies, capturing reflected signals at each frequency to create a composite image.

- Applications. Ideal for high-resolution imaging and detailed analysis of subsurface features in construction, engineering, and environmental studies.

When Is Ground Penetrating Radar Required?

Ground Penetrating Radar (GPR) is essential in various scenarios to ensure the quality, safety, and reliability of subsurface conditions.

Ground Penetrating Radar is required in various scenarios to ensure the safety, reliability, and efficiency of subsurface investigations. Its ability to provide detailed images of the subsurface quickly and non-invasively makes it an indispensable tool across multiple industries.

Here are key situations when GPR is required:

1. Construction and Engineering

- Utility locating. GPR is used to locate underground utilities such as pipes, cables, and conduits before excavation or drilling. This prevents damage to existing infrastructure and ensures safety.

- Structural assessment. GPR helps assess the integrity of structures such as bridges, roads, and buildings by detecting voids, cracks, and other anomalies within the materials.

2. Environmental Studies

- Contamination detection. GPR is employed to detect subsurface contamination such as buried tanks, drums, and waste. It helps identify the extent and depth of contamination for environmental remediation.

- Geological surveys. GPR is used to study geological formations, identifying features such as soil layers, rock formations, and groundwater tables. This information is crucial for construction planning and environmental impact assessments.

3. Archaeology

- Site mapping. GPR helps archaeologists map and identify subsurface features such as buried structures, artifacts, and graves without disturbing the site. It aids in planning excavations and preserving historical artifacts.

- Cultural heritage preservation. GPR is used to monitor and assess the condition of historical sites and monuments, ensuring their preservation and protection.

4. Utility Maintenance

- Pipeline inspection. GPR is used to inspect pipelines for defects, corrosion, and leaks. It helps maintain the integrity of the pipeline network and prevent failures.

- Water leak detection. GPR detects leaks in water distribution systems by identifying areas of moisture and voids around pipelines.

5. Mining and Mineral Exploration

- Ore body mapping. GPR is employed to map ore bodies and mineral deposits, providing valuable information for mining operations and resource estimation.

- Void detection. GPR helps detect voids and cavities in mining operations, ensuring the safety of workers and equipment.

6. Forensics and Law Enforcement

- Evidence location. GPR is used to locate buried evidence such as weapons, bodies, and other forensic materials. It aids in criminal investigations and search and rescue operations.

- Unmarked graves detection. GPR helps identify unmarked graves and burial sites, providing crucial information for historical and forensic investigations.

The Top 6 Sectors that Rely on Ground Penetrating Radar + Specific Applications They Use

Ground penetrating radar is a vital inspection method used across many industries and sectors, providing essential insights into subsurface conditions. Its ability to non-invasively image the subsurface makes it indispensable for ensuring safety, quality, and efficiency in various applications.

Here are some key applications of GPR, highlighting its versatility and importance:

1. Utility Maintenance and Inspection

GPR is essential for maintaining and inspecting underground utility networks.

- Pipeline inspection. GPR detects defects, corrosion, and leaks in pipelines, ensuring their integrity and preventing failures. It is particularly useful for water, gas, and sewer pipelines.

- Manhole and sewer inspection. GPR is used to inspect the condition of manholes and sewer lines, identifying issues such as blockages, cracks, and collapses.

2. Mining and Mineral Exploration

GPR is a useful mining tool, providing valuable information for resource exploration and safety.

- Ore body mapping. GPR helps map ore bodies and mineral deposits, aiding in resource estimation and mining planning.

- Void and cavity detection. GPR detects voids and cavities in mining operations, ensuring the safety of workers and equipment by identifying potential collapse zones.

3. Construction and Civil Engineering

The construction and civil engineering industries rely heavily on GPR to ensure the safety and integrity of infrastructure.

- Utility mapping. GPR is used to locate and map underground utilities, such as water pipes, electrical cables, and gas lines, before excavation or construction activities.

- Concrete inspection. GPR helps assess the condition of concrete structures by detecting voids, cracks, and rebar placement. This is crucial for ensuring the safety and longevity of bridges, buildings, and other concrete structures.

- Foundation analysis. GPR is used to evaluate the condition of foundations, identifying issues such as subsidence, voids, and soil compaction that could compromise structural integrity.

4. Environmental Studies

GPR plays a critical role in environmental studies by providing detailed information about subsurface conditions.

- Soil and groundwater mapping. GPR is used to map soil layers and groundwater tables, providing valuable information for environmental assessments, agriculture, and land development.

- Contaminant detection. GPR helps identify buried contaminants such as underground storage tanks, waste drums, and chemical spills, aiding in environmental remediation efforts.

- Sinkhole detection. GPR is employed to detect and monitor the formation of sinkholes, helping to prevent property damage and ensure public safety.

5. Archaeology and Cultural Heritage

In archaeology, GPR is invaluable for non-invasive exploration and preservation of historical sites.

- Site mapping. GPR is used to map archaeological sites, identifying buried structures, artifacts, and features without disturbing the ground. This information guides excavation efforts and helps preserve valuable historical artifacts.

- Grave detection. GPR helps locate unmarked graves and burial sites, providing crucial information for historical research and forensic investigations.

- Monitoring historical structures. GPR is used to assess the condition of historical buildings and monuments, detecting structural issues such as voids, cracks, and moisture intrusion.

6. Forensics and Law Enforcement

GPR is a crucial tool for forensic investigations and law enforcement.

- Evidence location. GPR is used to locate buried evidence such as weapons, bodies, and other forensic materials, aiding in criminal investigations and search and rescue operations.

- Unmarked graves. GPR helps identify unmarked graves and burial sites, providing crucial information for historical research and forensic investigations.

Best Practices for Ground Penetrating Radar

To ensure the effectiveness and reliability of ground penetrating radar (GPR) in subsurface investigations., it’s key to follow best practices.

Here are the top 9 areas to keep in mind for effective execution of GPR in the field.

1. Proper Training and Certification

- Qualified personnel. Ensure that GPR surveys are conducted by trained and certified technicians. Certification from recognized bodies such as the National Association of Testing Authorities (NATA) or equivalent organizations is essential. Properly trained personnel are more likely to conduct accurate surveys and correctly interpret results.

- Continuous education. Encourage ongoing education and training to keep technicians updated on the latest techniques, equipment, and industry standards. This can include workshops, seminars, and certification renewal courses. Staying current with industry developments helps maintain high standards of survey quality.

2. Appropriate Equipment Selection

- GPR system selection. Choose the appropriate GPR system based on the specific survey requirements. Consider factors such as antenna frequency, resolution, depth penetration, and portability. The correct system ensures the capture of detailed and accurate subsurface images.

- Calibration. Regularly calibrate GPR equipment using known standards to maintain accuracy and reliability. Calibration ensures that the equipment provides consistent and precise measurements.

3. Survey Planning and Preparation

- Site assessment. Conduct a thorough assessment of the survey site to identify potential challenges such as surface conditions, accessibility, and environmental factors. Understanding the site conditions helps in selecting the appropriate equipment and survey techniques.

- Grid and control points. Establish a grid and control points for the survey area to ensure systematic data collection. This helps in accurately mapping subsurface features and correlating them with surface locations.

4. Data Collection and Processing

- Systematic data collection. Follow a systematic approach to data collection, ensuring complete and overlapping coverage of the survey area. This helps in creating continuous and accurate subsurface images.

- Real-time monitoring. Utilize real-time monitoring software during surveys to detect and analyze subsurface features immediately. This allows for prompt adjustments and ensures comprehensive data collection.

- Data quality control. Regularly check the quality of the collected data during the survey. Look for issues such as signal noise, interference, and data gaps, and address them promptly to ensure accurate results.

5. Data Analysis and Interpretation

- Advanced software. Use advanced data processing software to analyze and interpret GPR data. This software enhances and filters the data, providing detailed subsurface images and reports.

- Expert interpretation. Ensure that GPR data is interpreted by experienced professionals who can accurately identify and assess subsurface features. Correct interpretation is crucial for making informed decisions based on the survey results.

- Comparative analysis. Compare current survey data with historical data to identify changes and trends in subsurface conditions. This helps in assessing the progression of potential issues and planning maintenance activities.

6. Documentation and Reporting

- Systematic documentation. Record and document survey data systematically, including subsurface images, identified features, and interpreted results. Accurate documentation helps in tracking subsurface conditions over time and provides valuable information for future surveys.

- Detailed reports. Generate detailed survey reports that include comprehensive analysis, interpreted results, and recommendations. Clear and concise reports aid in decision-making and project planning.

7. Regular Equipment Maintenance

- Routine checks. Perform regular maintenance and routine checks on GPR equipment to ensure it is in good working condition. This includes inspecting antennas, cables, batteries, and calibration equipment for wear and damage.

- Firmware and software updates. Keep firmware and software for GPR systems and analysis tools up-to-date to take advantage of the latest features and improvements. Regular updates help maintain the performance and accuracy of the equipment.

8. Safety Protocols

- Protective gear. Ensure that technicians wear appropriate protective gear, such as safety glasses, gloves, and protective clothing, especially when conducting surveys in hazardous environments. Safety gear helps prevent injury and ensures compliance with safety regulations.

- Safe handling of equipment. Follow safe handling procedures for GPR equipment and other survey tools. Proper handling minimizes the risk of equipment damage and ensures reliable performance.

- Environmental safety. When conducting surveys in environmentally sensitive areas, follow protocols to minimize disturbance and protect natural habitats. Ensure compliance with environmental regulations and best practices.

9. Compliance with Regulations

- Regulatory standards. Ensure compliance with all relevant regulatory standards and guidelines for GPR surveys. This includes obtaining necessary certifications and adhering to industry best practices. Compliance ensures that surveys meet required safety and quality standards.

- Inspections and audits. Conduct regular inspections and audits to verify compliance with safety protocols and regulatory requirements. Address any identified issues promptly to maintain a safe and compliant survey environment.