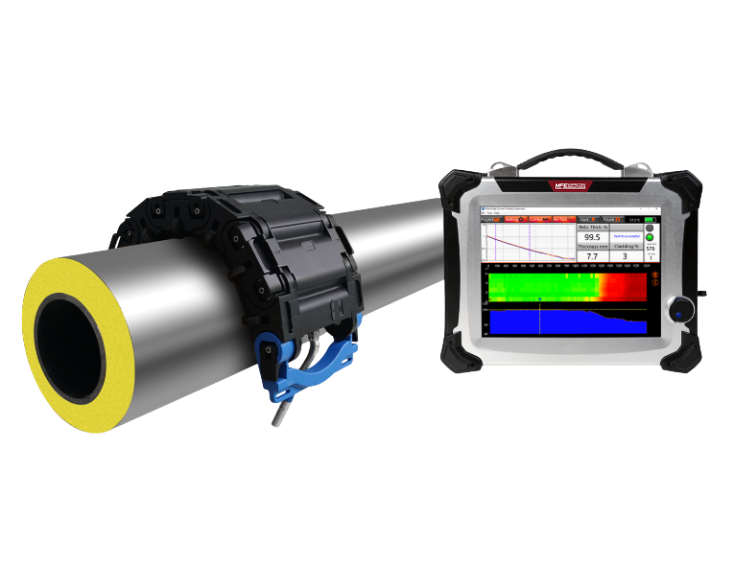

The MFE PulsePro is a durable, field-ready pulsed eddy current inspection system built for fast, non-intrusive evaluations—without removing insulation, halting operations, or dismantling equipment. Designed for demanding environments, this PEC system helps teams detect corrosion and wall loss in real time, keeping assets online and operations efficient.

Trusted across industries, the MFE PulsePro makes it easier to assess the condition of both ferrous and non-ferrous components, even through thick cladding or insulation. With intuitive controls and high-resolution data, it gives technicians the insight they need to make informed decisions safely, accurately, and without delays.

Equipment Type: Pulsed Eddy Current

Demande de devis

When it comes to keeping critical infrastructure running safely and efficiently, you can’t afford blind spots—especially the ones hidden under layers of insulation or metal cladding.

The MFE PulsePro is built to solve that exact problem. This powerful inspection tool uses pulse eddy current technology to detect corrosion and wall thinning in metal pipes, tanks, and vessels, without tearing off insulation or shutting down operations.

It’s a smarter, faster way to assess asset health and prevent costly failures. Whether you’re responsible for maintenance planning, regulatory compliance, or extending equipment life, the PulsePro gives you the data you need, right through the cover.

The PulsePro is engineered to maintain accuracy regardless of defect shape or orientation.

Its signal processing algorithm is not sensitive to irregular geometries, making it effective on localized corrosion, pitting, and general wall loss, even on components with elbows or complex profiles.

It supports both ferromagnetic metals like carbon steel and low-alloy steel, and non-ferromagnetic materials such as stainless steel and aluminum alloy.

With dedicated probes for each type and optional high-resolution or multi-channel configurations, PulsePro ensures broad material coverage with precise, dependable results across diverse inspection scenarios.

The PulsePro offers a full suite of interchangeable probes to match your inspection needs. Standard probes are available in small, medium, and large sizes for use on carbon steel and stainless steel, with optional high-resolution and array configurations for more detailed or high-volume scans.

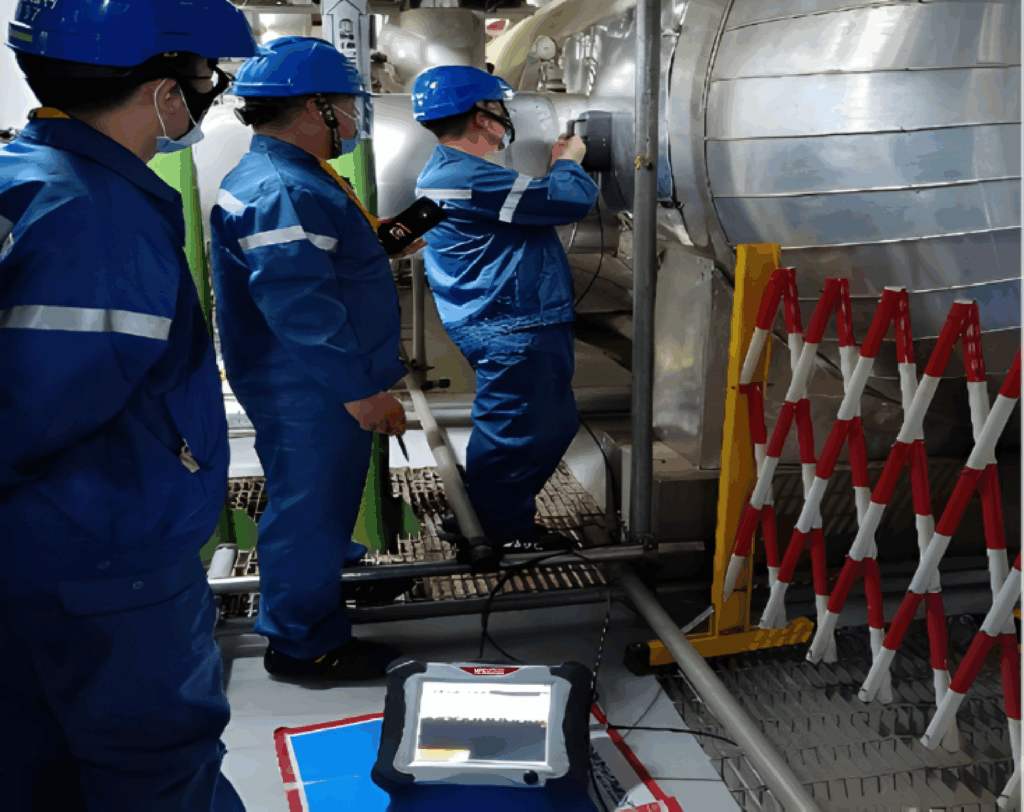

For enhanced accessibility, technicians can equip probes with optional extension rods (3 m or 5 m) and 30 m cables—ideal for reaching elevated, obstructed, or remote locations without repositioning equipment or compromising safety.

For large or high-risk areas, the PulsePro can be configured with an optional six-channel array probe designed for continuous scanning and C-scan imaging. The array uses a circular probe ring that wraps around insulated pipes and moves along the axis, either manually or electrically to collect dense PEC data in real time.

This configuration produces high resolution wall thickness maps, identifies potential corrosion zones automatically, and enhances inspection coverage for pipe diameters starting at 140 mm (5.5 in) and larger. It is especially effective for scanning long sections of piping or when rapid, wide-area coverage is essential.

The MFE PulsePro is built to detect corrosion through insulation and protective layers without requiring their removal.

In standard PEC mode, it can penetrate cladding up to 300 mm (12 in) thick when using stainless steel or aluminum jackets, and up to 150 mm (6 in) with iron coverings. This allows accurate measurement on fully insulated assets, saving time and cost on teardown.

The system is also rated for in-service operation from –200 °C to +800 °C (–58 °F to 1,472 °F), enabling inspections in high-temperature or cryogenic environments where traditional NDT tools fail. This makes PulsePro ideal for extreme conditions in power, chemical, and petrochemical plants.

The PulsePro’s probe is equipped with electronic focusing technology that enhances spatial resolution and corrosion defect recognition. This advanced signal control reduces electromagnetic interference, improving defect visibility even in noisy industrial environments.

In addition, the probe itself includes shortcut keys and an onboard LCD display, giving technicians immediate access to working status and live inspection data without needing to interact with the main unit.

This setup speeds up workflows, reduces operator fatigue, and supports efficient, single-operator field use, especially when working at height or in confined spaces.

Built for field reliability, the PulsePro features a fully sealed IP64-rated enclosure that protects against dust and water spray, along with a durable silicone sheath to resist drops and vibration. This makes it well-suited for harsh or unpredictable environments, including outdoor or high-traffic inspection zones.

The system also uses an AC/DC hybrid power supply with a built-in rechargeable lithium battery that supports 5+ hours of continuous operation, or more depending on usage conditions.

This combination ensures maximum uptime and minimal disruption, whether you’re inspecting remote assets or moving between multiple sites in a single shift.

The PulsePro offers a suite of optional modules that extend its functionality beyond standard PEC testing, giving inspection teams more flexibility, richer data, and better decision-making tools in the field. These add-ons support precise thickness measurement, visual documentation, and high-resolution defect mapping.

Optional Capabilities

Whether you’re managing aging infrastructure, planning turnarounds, or performing routine condition assessments, PulsePro helps you get more done—without tearing down insulation or halting operations.

Backed by reliable technology and proven in the field, it’s the PEC system that works where others can’t. Available for purchase or rental to fit your project needs.

| Temperature of Tested Medium | –200 °C to +800 °C |

| Working Temperature | –10 °C to +50 °C |

| Humidity | ≤ 85% R.H |

| Puissance | AC100–240V, 50Hz ±1%, ≤ 100 VA |

| Batterie | Built-in rechargeable lithium battery

(8 hours continuous use) |

| Main Unit Size/Weight | 436×278×136 mm, 7 kg |

| Probe Sizes | |

| Probe Cable Length | 5 m (≈16.4 ft) standard

30 m (≈98.4 ft) optional |

| Max Cladding Thickness | ≤ 300 mm (12 in) stainless steel/aluminum

≤ 150 mm (6 in) iron |

| Wall Thickness Detection Range | 2–100 mm (0.08–4 in) |

| Pipe Diameter | ≥ 21 mm (0.83 in) |

| Metal Protective Layer Thickness | ≤ 1 mm (0.04 in) |

| Repeated Detection Accuracy | ±0.02 |

| Corrosion Defect Sensitivity | 5% (volume ratio) |

| Measuring Speed | 15–0.5 measurements/sec (slower at higher wall thicknesses) |

| Max Cladding Thickness | ≤ 100 mm (4 in) for stainless/aluminum

≤ 80 mm (3 in) for iron |

| Wall Thickness Detection Range | 3–35 mm (0.12–1.38 in) |

| Minimum pipe diameter | ≥ 140 mm (5 1/2 in) |

| Metal Protective Layer Thickness | ≤ 1 mm (0.04 in) |

| Repeated Detection Accuracy | ±0.01 |

| Corrosion Defect Sensitivity | 5% (volume ratio) |

| Measuring Speed | 15–0.5 measurements per second (speed decreases with thicker walls) |

| Probe Cable Length | 5 m (16 ft) standard

30 m (98 ft) optional |

| Array Probe Size | 687.5 × 230 × 65 mm (27 × 9 × 2 1/2 in) |

| Array Probe Weight | 8.15 kg (18 lbs) |