The MFE Detect MW (MFE OGI) is an optical gas imaging camera designed to detect hydrocarbon gas leaks. This device can be used as a handheld device or a payload.

The MFE Detect MW (MFE OGI) uses advanced infrared technology to provide real-time imaging and precise leak detection, helping to improve safety and operational efficiency in industrial environments.

Equipment Type: Optical Gas Imaging Camera

Request a Quote

The MFE Detect MW (MFE OGI) camera includes a lightweight and ergonomic handle that offers several benefits to the operator. The handle provides a comfortable grip and improves the overall maneuverability of the device, allowing the operator to move and adjust the position of the camera easily.

The MFE Detect MW (MFE OGI) camera brings together the very latest in detector, cooler and lens design for optimizing the visualization of methane, propane, butane, and many other hydrocarbon gas leaks.

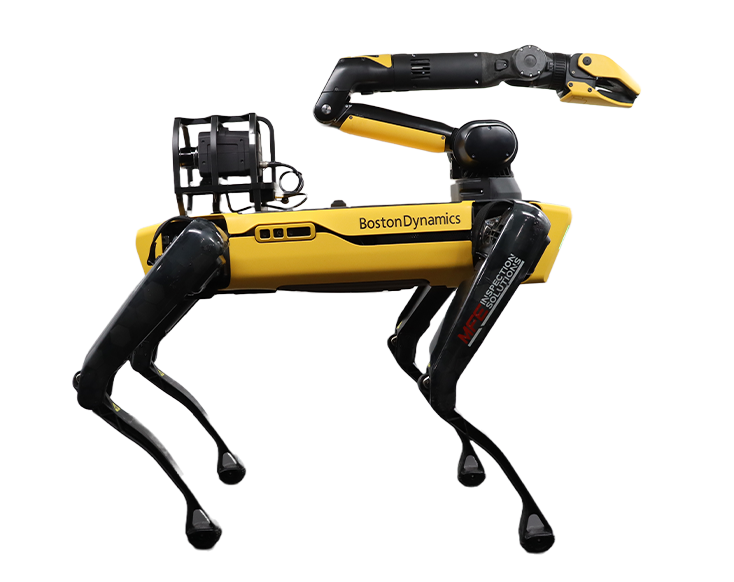

The MFE Detect MW (MFE OGI) is a multifunctional equipment solution that may be used as a handheld device or mounted onto Boston Dynamics’ Spot the agile, mobile robot.

By pairing the MFE Detect MW (MFE OGI) camera with Spot, operators may rely on Spot’s unprecedented mobility to automate routine inspection tasks. Then, when further inspection is required, the MFE Detect MW (MFE OGI) camera can be removed from Spot and used as a hand-held device.

The SmallRig VB50 Battery is a compact, high capacity li-battery, light weight in design and approximately 30% smaller than traditional V-mount batteries, making them easy to carry around.

Another convenient feature of the VB50 Battery is its practical OLED display. This display keeps track of the battery’s working status at all times, providing precise control and information for the user.

The MFE Detect MW (MFE OGI) utilizes a new state-of-the-art 640 x 512, 15µm pixel pitch “Hot MWIT” detector array with a special narrow bandpass cold filter in a miniature, long life, closed cycle, sterling cooler with an f/1.5 cold shield and an optimized purpose-built lens to provide unmatched thermal sensitivity.

The MFE Detect MW (MFE OGI) includes a built-in RGB Camera and a suite of advanced image processing functions, including automatic gain and dynamic contrast control, delivering visual acuity to operators for efficient leak detection and remediation.

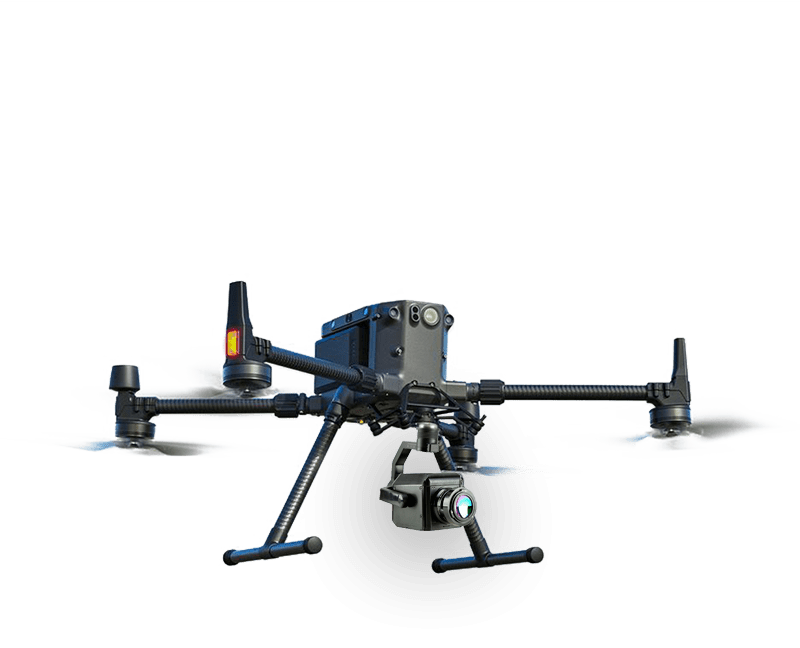

The MFE OGI 640 is the UAV-integrated version of the MFE OGI MW system, offering the same advanced optical gas imaging technology in a lightweight payload designed for aerial platforms. It delivers high-resolution detection of hydrocarbon gas leaks with the flexibility and reach of drone-based inspections.

Find answers to common questions about the MFE Detect MW, including its features, capabilities, and applications.

The MFE Detect MW has a resolution of 640 x 512 pixels, which is twice the resolution of the FLIR GF320 (320 x 240 pixels), allowing for clearer images. While the FLIR GF320 has a slightly wider field of view with its 23mm lens, the MFE Detect MW offers a narrower field of view with its 50mm lens, enabling it to capture finer details from further distances.

Quad-O compliance is specific to oil and gas facilities as of 2012. For cameras operating within the mid-wavelength range, compliance means they must be able to visualize 500 parts per million for positive identification of a gas leak.

The MFE Detect MW features a miniature, long-life, closed-cycle Stirling cooler. Cooled cameras like the MFE Detect MW may require cryocooler rebuilds after 10,000 to 13,000 hours of operation.

The MFE OGI operates in the mid-wavelength infrared range (3 to 5 micrometers), which is ideal for detecting hydrocarbon gas leaks with high sensitivity in industrial environments.