Guide

What Is LDAR? Your Guide to Leak Detection and Repair

LDAR (Leak Detection and Repair) is a regulatory process, defined by the U.S. EPA, used to identify and address leaks of volatile organic compounds (VOCs) and other hazardous gases in industrial facilities.

→ Jump to the top LDAR cameras for sale and rent of 2026.

LDAR programs help companies comply with the EPA’s LDAR regulations, which are aimed at reducing emissions and safeguarding the environment.

📘 EPA Guidance. Explore these EPA resources for official regulatory guidance on leak detection and repair, :

Why Is LDAR Important?

Industrial operations often involve equipment like valves, pumps, and pipelines that can develop leaks over time.

These leaks not only result in financial losses—they also pose significant environmental and safety risks. Following structured LDAR programs, companies can detect and repair leaks before they escalate, ensuring compliance with strict environmental standards.

The EPA LDAR regulations are part of broader initiatives to reduce air pollution, with specific requirements for monitoring, documenting, and addressing emissions from equipment.

But LDAR isn’t just about compliance—it’s also a strategic approach to improving efficiency and reducing costs.

In this guide, we’ll cover LDAR cameras, explore how LDAR works, the technologies involved, and provide answers to frequently asked questions.

Use the menu to the right to jump around, or keep reading for the top LDAR cameras on the market.

The Top LDAR Cameras for Sale and Rent of 2026

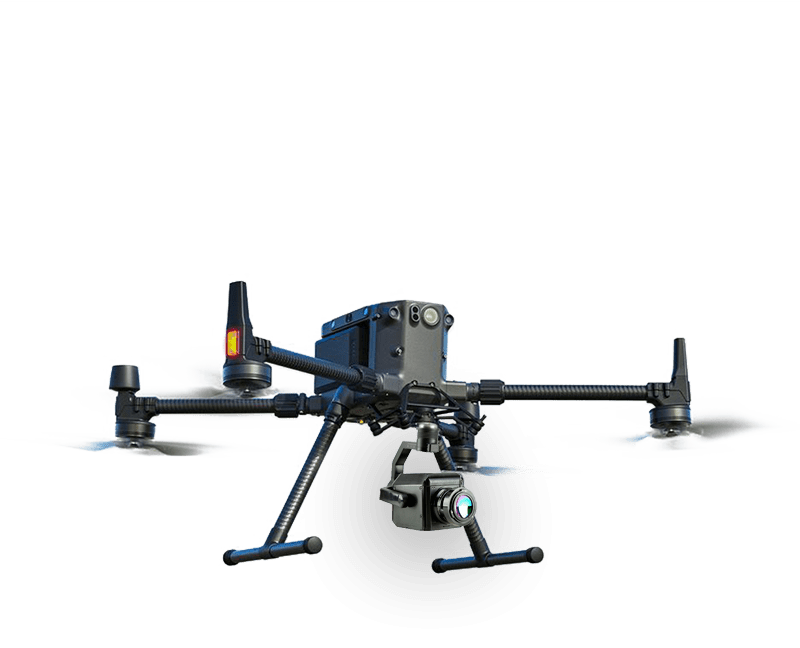

At MFE, we’ve developed two advanced LDAR cameras (also called OGI cameras, for Optical Gas Imaging). Both cameras can be carried by a drone and meet the EPA’s 40 CFR Part 60 Appendix K requirements, as well as the standards outlined in NSPS OOOOa, OOOOb, and OOOOc for methane emissions monitoring.

Gas detection drones help LDAR teams cover more ground with fewer risks and greater accuracy.

Further, according to the EPA’s LDAR Best Practices Guide, advanced tools like LDAR cameras “reduce survey time and improve safety, especially in hard-to-reach components.”

1. MFE Detect LW Optical Gas Imaging Payload

The MFE Detect LW is a field-tested long-wave infrared (LWIR) optical gas imaging payload for DJI M300/M350 drones, engineered for real-time methane leak detection over wide areas.

Key Features of the MFE Detect LW

- High-responsivity uncooled detector for real-time methane visualization.

- Seamless integration with DJI drones for efficient aerial inspections.

- Lightweight, durable design optimized for environmental compliance.

Learn more about the MFE Detect LW.

2. OGI – 640 Optical Gas Imaging Payload

The OGI-640 is a versatile mid-wave infrared (MWIR) optical gas imaging camera designed to integrate with a wide range of drone platforms.

It delivers high-resolution visual detection of hydrocarbons like methane and propane—making it ideal for aerial LDAR surveys in oil & gas, utilities, and industrial processing.

Key Features of the OGI-640

- High sensitivity to hydrocarbons.

- Real-time gas imaging.

- Capable of operating in diverse environmental conditions.

How LDAR Works

Leak Detection and Repair (LDAR) programs use a systematic approach to identify and address leaks of harmful gases, such as volatile organic compounds (VOCs) and methane, in industrial facilities.

These programs rely on advanced technologies and skilled personnel to ensure emissions are minimized, regulatory compliance is maintained, and operational efficiency is optimized.

Here’s a breakdown of the three key steps for LDAR:

1. Leak Detection

The first step in an LDAR program is identifying potential sources of leaks.

Inspectors use specialized equipment to monitor components and detect leaks—particularly from valves, flanges, connectors, pumps, and compressors.

Leak detection methods include:

- Optical Gas Imaging (OGI). OGI cameras use infrared technology to visualize gas leaks, making invisible emissions visible to inspectors in real time.

- Sniffer Devices (EPA Method 21). These handheld detectors measure gas concentrations at specific points and are approved for use under EPA LDAR protocols.

- Ultrasonic Leak Detectors. These devices detect the high-frequency sound of gas escaping under pressure—useful in noisy or high-traffic industrial environments.

During inspections, an LDAR technician systematically scans each component, documenting the location, size, and type of any emissions detected.

Depending on the facility’s regulatory classification, inspections may be required on a monthly, quarterly, or annual basis.

2. Leak Repair

Once a leak is identified, the next step is to repair it* promptly to minimize emissions and maintain compliance.

The repair process includes:

- Equipment replacement. Replace damaged components like gaskets or seals to restore system integrity.

- Tightening connections. Correct loose flanges, fittings, or valves to eliminate small leaks.

- Temporary fixes. Use sealants or clamps as interim solutions until full repairs can be made.

*According to the EPA’s LDAR manual, leaks must be repaired within a timeframe of 5 to 30 days, depending on the severity and regulatory requirements.

3. Confirmation Testing

All repairs must be followed by confirmation testing to ensure the leak has been successfully addressed.

Detailed documentation is also required, including records of the leak detection date, repair actions taken, follow-up results, and technician notes for compliance audits.

The Importance of LDAR in Environmental Compliance

LDAR plays a crucial role in helping companies meet stringent environmental standards, particularly in industries where emissions of volatile organic compounds (VOCs) and methane are a concern.

By systematically detecting and repairing leaks, LDAR programs not only reduce harmful emissions—they also ensure compliance with EPA LDAR regulations.

“Routine LDAR inspections can prevent significant emissions and reduce operational risks, particularly when focused on valves, connectors, and pumps.”

Reducing VOC and Methane Emissions

VOCs and methane are among the most common pollutants emitted by industrial operations.

VOCs contribute to the formation of ground-level ozone, which negatively impacts air quality and human health, while methane is a potent greenhouse gas that accelerates climate change.

LDAR programs significantly reduce these emissions by:

- Identifying leaks early, before they become larger and more costly to address.

- Ensuring that repair actions are taken promptly to prevent further emissions.

- Providing ongoing monitoring to maintain long-term control of emissions sources.

Ensuring EPA Compliance

The EPA has specific LDAR regulations that require companies to regularly inspect equipment, document findings, and repair leaks within defined timeframes.

Here are some key compliance requirements:

- Meeting inspection frequency requirements as outlined in EPA guidelines (monthly, quarterly, or annually depending on facility type).

- Using approved detection technologies like LDAR cameras (i.e., OGI cameras) or Method 21 sniffers.

- Maintaining detailed records of inspections, repairs, and emissions reductions.

Contributing to Sustainability Goals

In addition to regulatory compliance, LDAR programs can help companies meet broader sustainability goals.

Many companies are adopting LDAR as part of their corporate social responsibility (CSR) initiatives, recognizing its value in reducing their carbon footprint.

LDAR programs contribute to sustainability by:

- Reducing greenhouse gas emissions, particularly methane.

- Enhancing energy efficiency by preventing product loss through leaks.

- Demonstrating a commitment to environmental stewardship, which can improve stakeholder trust and brand reputation.

LDAR Program Templates for Compliance

Implementing a successful LDAR program starts with a clear and actionable plan.

A well-designed LDAR program template ensures that all aspects of compliance are addressed, from equipment selection and inspection schedules to repair protocols and reporting mechanisms.

Typical elements of an LDAR program template include:

- Defined inspection frequencies for each component type (valves, pumps, etc.)

- List of approved detection tools (e.g., OGI cameras, sniffers)

- Standard repair timeframes aligned with EPA guidelines

- Documentation and record-keeping protocols for audits

These templates provide a structured approach to managing emissions and maintaining regulatory compliance, simplifying the process for companies navigating complex requirements.

The 6 Types of LDAR Equipment

Effective LDAR programs rely on specialized equipment to identify, monitor, and address gas leaks safely and efficiently.

From visual gas imaging to real-time data systems, LDAR tools play a central role in meeting EPA regulations and minimizing emissions.

Keep reading to learn about the six types of LDAR equipment inspectors use to find leaks.

1. LDAR Cameras

LDAR cameras, also known as Optical Gas Imaging (OGI) cameras, use infrared technology to visualize gas leaks that are invisible to the naked eye. These are among the most widely used tools for leak detection in high-risk industrial environments.

- Used for aerial and ground-based inspections of pipelines, valves, tanks, and compressors

- Commonly detect methane, propane, and other hydrocarbons from a distance

- Required for compliance with standards like EPA 40 CFR Part 60 Appendix K

LDAR cameras are essential for facilities looking to comply with EPA OOOOa, OOOOb, and OOOOc rules and are especially effective in facilities where access to components is limited.

2. Portable Gas Detectors

Portable gas detectors are handheld instruments used to measure concentrations of VOCs or methane near suspected leak sources. They are frequently used in follow-up inspections to verify emissions detected during visual scans.

- Provide quantitative leak measurements on-site

- Useful for verifying small or borderline leaks seen with OGI tools

- Often used for LDAR recordkeeping and documentation

3. Ultrasonic Leak Detectors

Ultrasonic detectors pick up the sound of pressurized gas escaping through small openings. They’re ideal in noisy settings, since they rely on frequencies outside human hearing range.

- Effective in compressor stations, refineries, or manufacturing plants

- Do not require direct line of sight to detect leaks

- Best for high-pressure gas leaks that produce strong acoustic signatures

4. Fixed Monitoring Systems

Fixed LDAR systems are installed in high-risk areas to continuously monitor for leaks. These sensors can detect specific gases and trigger alerts if concentrations exceed a threshold.

- Provide 24/7 leak surveillance for storage tanks, loading zones, and compressor stations

- Often tied into facility SCADA systems for real-time alerts

- Reduce the need for frequent manual inspection in critical zones

5. Ground-Based Sensors and Correlators

Some LDAR inspections—especially those in municipal or underground pipeline networks—use correlators and ground microphones to triangulate the location of a leak based on sound intensity and timing.

- Frequently used in water and gas utilities for buried pipeline inspections

- Require calibration and skilled operators to interpret acoustic data

- Often paired with GIS mapping tools for location documentation

6. Advanced Technologies: Drones and AI

Drones equipped with OGI sensors have transformed LDAR inspections by enabling efficient, large-area coverage. These platforms are particularly useful in hard-to-reach areas like flare stacks, remote well sites, and elevated piping systems.

- Allow for aerial scanning of large facilities in less time

- Increase safety by minimizing technician exposure to hazardous zones

- Can carry LDAR payloads that meet EPA Appendix K guidelines

LDAR Regulations and Standards

LDAR programs are governed by a framework of federal regulations and industry standards designed to reduce fugitive emissions of volatile organic compounds (VOCs), methane, and other hazardous air pollutants.

These regulations—most notably those established by the EPA—ensure that industrial facilities proactively monitor, detect, and repair leaks to protect both the environment and public health.

EPA Guidance:

- EPA LDAR Best Practices Guide–Practical guidance on equipment inspections, leak thresholds, and compliance planning.

- EPA Protocol for Equipment Leak Emission Estimates (PDF)–The full technical manual used by regulators and inspectors.

EPA LDAR Requirements

The EPA’s LDAR regulations apply primarily to facilities in the oil and gas, chemical, and manufacturing sectors, where leaks can lead to significant emissions.

Here are the main requirements:

- Regular inspections. Equipment must be monitored at scheduled intervals, often quarterly, depending on the type of process and component.

- Approved detection methods. Companies must use Method 21 instruments, optical gas imaging (OGI) cameras, or other EPA-approved tools to identify leaks.

- Leak thresholds. VOC leaks are typically flagged at a concentration of 500 ppmv or greater, though thresholds may vary by equipment type and regulation.

- Repair deadlines. Per EPA guidance, initial repair must be attempted within 5 calendar days of detection. Final repair must occur within 15 calendar days, or up to 30 days with documented justification for delay.

- Record-keeping. Facilities must maintain thorough records of inspection dates, leak findings, repair actions, and emissions reductions to demonstrate compliance during audits.

Industry-Specific LDAR Guidelines

Beyond general EPA requirements, specific industries have developed additional LDAR standards to address unique operational and safety risks.

Here’s how LDAR is commonly used across the industries that rely on it.

Oil and Gas Industry

In upstream and midstream oil and gas operations, LDAR programs focus on components like compressors, wellheads, storage tanks, and pipelines.

The EPA’s New Source Performance Standards—specifically OOOOa, OOOOo, and OOOOc—establish detailed rules for methane monitoring using OGI cameras. These rules reference Appendix K, which sets the methodology and performance standards for OGI-based inspections.

Chemical Processing

In chemical manufacturing, LDAR programs prioritize leak-prone components like agitators, pressure relief valves, and connectors.

The Chemical Manufacturing Area Sources (CMAS) rule and Benzene Waste Operations NESHAP (BWON) both require facilities to use rigorous monitoring and repair procedures to limit VOC emissions.

Manufacturing

Manufacturing plants rely on LDAR to manage emissions from production lines, exhaust systems, and raw material storage.

These programs often overlap with OSHA general industry standards and EPA requirements, emphasizing worker safety alongside environmental performance.

Real-World Examples of LDAR Compliance

- Chevron. Implemented a drone-based methane inspection program using OGI cameras and AI analytics to comply with Quad OA standards and reduce methane leaks across remote well sites.

- Dow Chemical. Uses a comprehensive LDAR strategy that includes quarterly inspections, detailed repair logs, and digital record-keeping to maintain compliance with CMAS regulations.

- ExxonMobil. Deployed drone-mounted gas cameras to detect fugitive emissions along pipeline corridors, significantly speeding up inspections and reducing manual labor costs.

LDAR Compliance Guides

To simplify compliance planning, many reputable organizations offer LDAR templates, regulatory summaries, and best practice guides.

Here are some resources to help you with LDAR compliance:

- EPA Leak Detection and Repair: A Best Practices Guide. A comprehensive EPA guide covering detection methods, repair timelines, recordkeeping, and regulatory context.

- API: Leak Detection and Repair Guide. Best practices and technical references for LDAR in upstream and midstream oil and gas operations.

- American Gas Association: Methane Emissions Reduction. Industry-focused guidance and case studies for LDAR program development and emissions control.

- GPA Midstream: Technical Guidance Documents. Includes LDAR program design, component classification, and emissions reporting guidelines.

LDAR Training and Certification

Proper training and certification are essential for LDAR technicians to ensure the success of any LDAR program.

“The effectiveness of an LDAR program is strongly influenced by the capabilities of the personnel performing leak detection.” — EPA LDAR Best Practices Guide

Skilled personnel are not only critical to maintaining compliance with EPA regulations—they also help reduce emissions, avoid false positives, and ensure repairs are completed effectively.

Why LDAR Training Matters

Technicians are on the front lines of emissions management.

Their ability to correctly use leak detection tools and follow regulatory protocols determines the overall reliability of an LDAR program.

Quality training helps:

- Ensure accurate leak detection and minimize false positives.

- Reduce the risk of non-compliance and associated penalties.

- Improve efficiency in inspections, documentation, and repairs.

- Maintain consistency in results across facilities and inspection teams.

Core Competencies for LDAR Technicians

Successful LDAR technicians must have a mix of technical knowledge, regulatory awareness, and hands-on skill.

Typical competencies include:

- Operation of OGI cameras, sniffer devices, and Method 21-compliant analyzers.

- Understanding of EPA LDAR regulations, including 40 CFR Part 60 and Appendix K.

- Ability to identify, quantify, and document gas leaks using approved methods.

- Familiarity with safety standards, including VOC handling and confined space protocols.

- Strong data management and documentation skills using digital or paper-based logs.

What’s Covered in LDAR Training

A comprehensive LDAR training program typically includes the following modules:

- Program overview. Introduction to LDAR concepts, regulations, and environmental impact

- Regulatory compliance. Detailed review of relevant EPA rules, including 40 CFR Part 60, Subparts OOOOa/b/c, Appendix K, and Method 21 protocols

- Leak detection methods. Hands-on training with OGI cameras, flame ionization detectors (FID), and photoionization detectors (PID)

- Inspection procedures. Step-by-step techniques for identifying and verifying leaks, tagging equipment, and recording results

- Repair protocols. EPA-recommended timelines for leak repair and follow-up verification steps

- Safety and PPE. VOC safety, confined space awareness, and personal protective equipment usage

- Documentation and reporting. Best practices for logbooks, compliance software, and audit preparation

Some advanced programs also include modules on drone-assisted LDAR inspections, emissions quantification, and digital data management tools.

Common Challenges in LDAR Programs

Implementing an effective LDAR program is often easier said than done.

Without careful planning, the challenges involved can undermine compliance efforts and expose companies to regulatory fines, operational disruptions, or reputational damage.

Here’s an overview of the most common challenges and how to solve them:

| Challenge | Recommended Solution |

|---|---|

| Outdated or inaccessible equipment | Upgrade to modern tools like OGI drones; ensure regular calibration |

| Technician skill and certification gaps | Launch structured LDAR training and certification programs |

| Complex or overlapping regulations | Create a flexible LDAR program template that meets EPA and local requirements |

| Data management overload | Implement centralized reporting systems and analytics tools |

| High initial and ongoing costs | Use scalable technologies; pursue emissions-reduction funding |

Here’s more information on each challenge and how to solve it.

1. Equipment Limitations

Many LDAR programs struggle with the limitations of older or inappropriate detection technologies.

Common issues include:

- Low sensitivity of outdated equipment, which may miss small or intermittent leaks.

- Inaccessibility of components like elevated pipelines or enclosed spaces for traditional handheld inspections.

- High upfront costs of advanced technologies, including Optical Gas Imaging (OGI) cameras and drone systems.

Solution: Upgrade to modern LDAR technologies, such as OGI cameras mounted on drones, to improve coverage and leak detection sensitivity. Ensure all equipment is routinely calibrated and maintained to meet operational and regulatory standards.

2. Training and Certification Gaps

Effective LDAR programs rely on skilled technicians who can operate equipment, identify leaks, and properly document inspections.

But many companies encounter gaps in training or certification. These gaps can lead to poor data collection, compliance issues, or safety incidents.

- Lack of hands-on experience with newer detection tools.

- Insufficient knowledge of EPA LDAR requirements and documentation protocols.

- Limited safety training for hazardous environments.

Solution: Implement a structured LDAR training program that includes certification pathways, such as API or state-level credentials. Refresher courses and certification renewals help maintain technician readiness over time.

3. Complex LDAR Regulations

LDAR regulations can be complex, especially for companies operating across multiple states or under overlapping federal rules.

Staying compliant with EPA standards while managing state-specific variations often requires significant administrative effort.

- Differences between state and federal LDAR requirements.

- Extensive documentation and record retention obligations.

- Frequent updates to regulations and compliance procedures.

Solution: Build a flexible LDAR program template that incorporates both federal rules—such as those found in EPA’s LDAR guidelines—and state-specific requirements. EPA’s LDAR Best Practices Guide recommends routine inspections and repairs within 5 to 30 days, depending on the component. Use compliance tracking software to monitor changes in regulation and automate reporting wherever possible.

4. Data Management and Reporting

LDAR inspections generate significant volumes of data—from leak logs to repair timelines.

Without strong systems in place, managing this information can quickly become overwhelming.

- Disorganized inspection and repair records.

- Non-standardized reporting formats that hinder audits or EPA compliance checks.

- Limited ability to analyze data for trends or performance improvements.

Solution: Use centralized data management platforms that allow for standardized, searchable record-keeping. AI-powered analytics tools can identify leak trends, track maintenance performance, and support more informed decision-making.

5. High Implementation Costs

For many organizations, the cost of launching a new LDAR program—or upgrading an existing one—can be a major barrier.

Expenses often include equipment purchases, training, software licenses, and ongoing maintenance.

- High costs for advanced detection tools and compliance platforms.

- Resources needed to onboard and train qualified LDAR technicians.

- Budget strain from ongoing upgrades and recalibration of gear.

Solution: Adopt a phased approach by investing in modular or scalable LDAR technologies that can grow with your operations. Explore grant programs and state or federal incentives aimed at emissions reduction initiatives to offset upfront costs.

Frequently Asked Questions About LDAR

Here are answers to the most commonly asked questions about LDAR.

What is LDAR?

LDAR stands for Leak Detection and Repair, a regulatory program used to detect and fix fugitive emissions—especially volatile organic compounds (VOCs) and methane—from industrial equipment. LDAR programs are required by environmental regulations such as those enforced by the U.S. Environmental Protection Agency (EPA).

Why is LDAR important?

LDAR plays a critical role in reducing harmful emissions, improving air quality, and maintaining regulatory compliance. By proactively identifying and repairing leaks, companies can minimize environmental impact, reduce safety risks, and avoid costly fines related to non-compliance.

What equipment is used in LDAR programs?

LDAR programs use a range of technologies, including Optical Gas Imaging (OGI) cameras, portable gas detectors, and fixed monitoring systems. These tools help technicians detect leaks with accuracy and consistency. Learn more about LDAR cameras and detection tools.

How do I become an LDAR technician?

To become an LDAR technician, you typically need to complete an LDAR training program that includes hands-on experience with detection equipment and a strong understanding of regulatory compliance. Certification may be offered through third-party programs or required by state or facility-specific guidelines.

What are the EPA requirements for LDAR?

The EPA requires industrial facilities to monitor components such as valves, connectors, compressors, and pipelines for leaks on a scheduled basis. According to the EPA’s LDAR Best Practices Guide, leaks must generally be repaired within 5 to 30 days, depending on component type and severity. Facilities must maintain thorough inspection and repair records, often for a minimum of two years.

What is the LDAR database?

An LDAR database is a centralized system used to track inspections, leaks, repairs, and compliance documentation. Maintaining an accurate database is critical for demonstrating regulatory compliance, identifying leak trends, and streamlining audits. Many companies use cloud-based platforms or custom software to manage their LDAR data efficiently.

What are the requirements for LDAR tagging?

LDAR tagging refers to the labeling of components subject to leak detection, typically with a unique identifier that includes location, equipment type, and inspection history. Proper tagging enables traceability, supports accurate recordkeeping, and simplifies compliance audits.

How often should LDAR inspections be performed?

Inspection frequency depends on the component type and applicable regulations. For example, valves are often inspected quarterly, pumps monthly, and connectors biannually. EPA regulations such as OOOOa provide specific inspection schedules that facilities must follow.

Is LDAR required for all facilities?

LDAR requirements primarily apply to facilities that handle VOCs or methane, such as chemical plants, oil and gas operations, and refineries. Whether LDAR is mandatory depends on your facility’s emissions classification and the applicable local, state, or federal regulations. Small facilities may be exempt under certain thresholds, but many are still encouraged to adopt LDAR practices voluntarily to reduce environmental impact and improve operational safety.