Ressources / Guide / Noise Dosimeters: Top Models on the Market & More

Guide

Noise Dosimeters: Top Models on the Market & More

A noise dosimeter is a device worn by workers in loud environments that captures continuous, real-world sound data.

Unlike handheld sound level meters that take spot readings, dosimeters calculate a time-weighted average of noise exposure, providing a clearer picture of overall risk.

→ Jump to the best noise dosimeters of 2026.

In industrial environments, noise is more than an inconvenience—it’s a serious safety concern.

Workers in places like factories, refineries, and construction sites are often exposed to high levels of sound that can cause permanent hearing loss if not carefully monitored. To protect workers and comply with OSHA and NIOSH regulations, companies use noise dosimeters for environmental monitoring to measure an individual’s cumulative noise exposure throughout a shift.

For sitewide oversight, noise dosimeters can stream data into an environmental monitoring system (EMS), enabling continuous alerts, audit-ready records, and trend reporting across crews, areas, and shifts.

Other common terms for noise dosimeters include:

Personal noise dosimeters

- Noise exposure meters

- Occupational noise monitors

- Personal sound exposure meters (PSEMs)

- Worker noise dosimeters

- Industrial noise dosimeters

In this guide, you’ll learn what noise dosimeters are, how they work, and how to choose and use them effectively in industrial environments.

Use the menu to the right to jump around, or continue reading for the full guide.

Best Noise Dosimeters for Sale + More Environmental Monitoring Tools

Modern noise dosimeters have evolved far beyond the basic clip-on instruments of the past.

Today’s models provide real-time data logging, wireless connectivity, and intuitive software integration that simplify compliance tracking and hearing conservation reporting. These advancements make them essential tools for industrial hygiene teams, EHS managers, and safety professionals responsible for monitoring workplace noise exposure.

[Lire aussi : Environmental Monitoring Tools & Equipment: 2026 Buyer’s Guide]

Below is one of the leading noise dosimeters available today, followed by additional acoustic monitoring tools for comprehensive industrial noise assessment.

1. Casella CEL-350IS—Noise Dosimeter

The CEL-350IS is a compact, intrinsically safe noise dosimeter that tracks a worker’s total sound exposure across an entire shift. It clips to clothing and records dose, TWA, and time-history data to help safety teams maintain compliance with OSHA and NIOSH standards.

Built for rugged industrial use, the CEL-350IS is lightweight, simple to operate, and automatically calibrates for quick deployment across multiple workers.

- Intrinsically safe. Certified for use in hazardous oil & gas, chemical, and manufacturing environments.

- Comprehensive exposure tracking. Captures dose, TWA, and time-history for hearing conservation programs.

- Compact design. Clips securely to clothing for all-day comfort.

- Auto-calibration. Compatible with standard acoustic calibrators for fast, reliable checks.

2. TSI Quest Edge 8—Noise Dosimeter

The TSI Quest Edge 8 is a compact, cable-free noise dosimeter engineered for accurate, full-shift exposure monitoring.

Designed for worker comfort and mobility, it mounts near the ear and continuously tracks personal noise levels throughout the day. Its durable housing and intuitive interface make it ideal for industrial hygiene programs in manufacturing, construction, energy, and other high-noise sectors.

- Wireless monitoring. Bluetooth connectivity enables live data viewing and remote control via mobile app.

- Dual-parameter measurement. Capture multiple exchange rates (3 dB / 5 dB) to meet OSHA, NIOSH, and ISO standards.

- Compact, cable-free design. Lightweight and easy to wear, minimizing interference during daily tasks.

- Comprehensive data logging. Stores up to 180 hours of measurements with time history for detailed analysis.

- Rugged and reliable. Intrinsically safe model available for hazardous environments (ATEX/IECEx).

Buy or rent the TSI Quest Edge 8 noise dosimeter.

Related Environmental Monitoring Tools

In addition to heat stress monitors, MFE Inspection Solutions offers these other sound-related environmental monitoring tools.

3. Casella CEL-633.A1.K1 Kit—Sound Level Meter

The CEL-633.A1.K1 is a handheld digital sound level meter for precise industrial and environmental noise assessments. It measures real-time sound pressure levels with selectable frequency and time weightings to ensure accurate, repeatable readings.

A bright, high-resolution screen and simple menu system make it easy to configure, capture, and review data in the field. Built-in logging and PC connectivity streamline reporting for compliance and long-term monitoring.

- Versatile measurement options. Multiple frequency and time weightings for diverse survey conditions.

- Detailed reporting. Integrated data logging and PC transfer for quick analysis.

- Readable display. Backlit, high-resolution interface for use in low-light environments.

- Smart calibration. Automatic level adjustment when used with compatible calibrators.

Rent the Casella CEL-633.A1.K1 Kit.

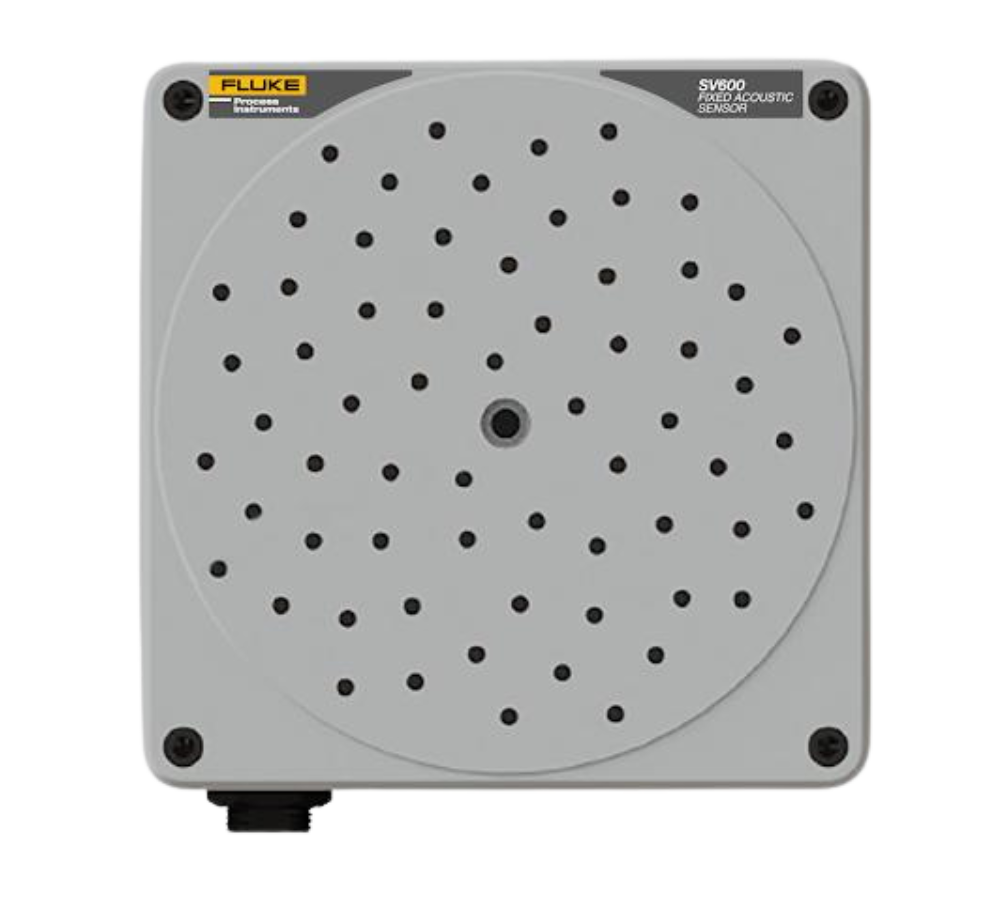

4. Fluke SV600—Acoustic Imager

The Fluke SV600 transforms sound into a live visual SoundMap, allowing maintenance teams to identify compressed-air or gas leaks and mechanical issues in real time. It can be mounted permanently or integrated with robotic systems for automated inspections.

By visualizing sound, the SV600 shortens troubleshooting time, reduces wasted energy from leaks, and supports predictive maintenance strategies.

- Real-time sound visualization. Acoustic mapping reveals precise leak locations instantly.

- Automation-ready. Integrates with mobile robots for autonomous rounds.

- Proactive maintenance. Detects abnormal sound patterns before failures occur.

5. Crysound 2623—Acoustic Imager

The Crysound 2623 is a handheld acoustic camera designed to locate and visualize sound sources for quick diagnostics. It identifies leaks, vacuum losses, and electrical partial discharges, giving maintenance teams clear insight into asset performance.

Its durable design and straightforward interface make it an efficient solution for field technicians working across large industrial facilities.

- Beamforming array. Locates noise sources with high confidence and accuracy.

- Leak and discharge detection. Supports both air/gas leak and PD inspections.

- Instant reporting. Capture and export images or videos directly from the device.

- Built for the field. Rugged aluminum housing withstands tough industrial conditions.

Buy or rent the Crysound 2623.

6. Crysound 8124—Acoustic Imager

The Crysound 8124 combines a dense microphone array with a high-resolution display to visualize air and gas leaks as well as electrical discharge across large assets. It’s designed for extended use in expansive industrial environments.

With advanced frequency range and long battery life, the 8124 delivers accurate results over long inspection routes without sacrificing detection sensitivity.

- High-density microphone array. 200 microphones for long-range, precise localization.

- Wide frequency bandwidth. Detects subtle leak and discharge sounds up to 100 kHz.

- Dual-mode documentation. Generates acoustic and optional thermal image reports.

- Optimized for field work. Large 1920×1200 screen and up to 5 hours of runtime.

What Is a Noise Dosimeter?

A noise dosimeter is a precision instrument used to measure a worker’s cumulative exposure to sound over time.

Also called a personal noise dosimeter or noise exposure meter, it continuously records sound pressure levels throughout a work shift to calculate the total noise dose experienced by an individual.

Noise dosimeters form the foundation of hearing conservation and compliance programs, providing the data needed to meet OSHA and NIOSH requirements for occupational noise exposure.

In high-noise environments such as refineries, manufacturing plants, construction sites, and power generation facilities, these devices help safety professionals determine when noise levels exceed safe limits and when additional hearing protection or engineering controls are required.

The 4 Core Functions of a Noise Dosimeter

Every noise dosimeter collects and processes data using these core functions:

- Microphone. Detects sound pressure variations near the worker’s ear and converts them into electrical signals.

- Processor and memory. Analyze, calculate, and store exposure data such as dose, time-weighted average (TWA), and peak levels.

- Interface and indicators. Display status lights, readouts, or digital screens to show operation and threshold exceedances.

- Power and calibration system. Provide consistent operation through the shift and allow pre/post-use calibration checks for accuracy.

Professional noise dosimeters are designed for continuous monitoring, capturing every change in sound level as workers move through different environments. The resulting data gives a true representation of real-world exposure—something spot measurements cannot provide.

Although the term “noise meter” is sometimes used informally, true noise dosimeters go further. They measure, average, and record exposure across time, providing defensible data that meets recognized industrial and regulatory standards for accuracy and repeatability.

Noise Dosimeters vs. Other Sound Measurement and Acoustic Inspection Tools

Noise dosimeters are the primary tools for measuring and managing personal noise exposure in the workplace.

They form the backbone of most hearing conservation and compliance programs, working alongside sound level meters, acoustic imagers, and other diagnostic tools.

In industrial environments, safety teams often use multiple instruments together—dosimeters for personal exposure tracking, sound level meters for area monitoring, and acoustic imaging systems for identifying and correcting noise sources.

Understanding how each of these tools fits within a noise assessment program helps determine the right mix for comprehensive monitoring.

Comparison of Noise Dosimeters and Related Sound Measurement Tools

| Tool | Primary Function | Common Industrial Uses |

|---|---|---|

| Noise Dosimeter | Worn by workers to measure and record cumulative personal noise exposure over time | Hearing conservation programs, OSHA compliance, individual exposure tracking |

| Sound Level Meter | Measures real-time sound pressure levels in decibels (dB) for area or environmental noise checks | Worksite noise surveys, machinery noise checks, compliance spot measurements |

| Integrating Sound Level Meter | Calculates average sound energy over a defined period to produce continuous equivalent levels (Leq) | Long-term monitoring, noise mapping, community noise studies |

| Sound Analyzer | Performs advanced frequency and time-history analysis for detailed acoustic evaluation | Engineering diagnostics, frequency-based testing, equipment noise analysis |

| Vibration Meter | Measures vibration magnitude and frequency, often used alongside noise data for condition monitoring | Machinery maintenance, bearing diagnostics, predictive maintenance |

| Acoustic Camera / Microphone Array | Uses multiple microphones and imaging software to display sound intensity and source location in real time | Compressed air and gas leak detection, electrical partial discharge localization, environmental noise visualization |

How to Use These Tools Together

Use this workflow to combine noise dosimeters with complementary sound-measurement tools for complete, defensible noise assessments.

- Start with Noise Dosimeters to measure personal exposure (dose, TWA) across full work shifts and identify employees at risk of overexposure.

- Use Sound Level Meters for quick area checks and baseline readings that reveal noise hotspots before deploying dosimeters.

- Apply Integrating Sound Level Meters for long-term monitoring or to establish environmental Leq values for noise mapping and trend analysis.

- Leverage Sound Analyzers to pinpoint problem frequencies or tonal components and support engineering noise control solutions.

- Deploy Acoustic Cameras or Microphone Arrays to visualize noise and locate sources such as air leaks, fans, or electrical discharge.

- Pair with Vibration Meters to correlate mechanical vibration with noise for predictive maintenance and root-cause analysis.

Coordinating these instruments within a single monitoring program helps safety teams link personal exposure with environmental sources, streamline documentation, and verify the effectiveness of corrective actions.

How Noise Dosimeters Work

Noise dosimeters continuously measure sound to calculate how much noise a person is exposed to during a work shift. Instead of capturing a single snapshot, they accumulate exposure over time, giving a complete picture of a worker’s daily sound environment.

How Dosimeters Capture Exposure

A sensitive microphone and onboard processor record sound pressure thousands of times per second. The instrument then converts these readings into exposure data that accounts for both how loud the noise is and how long the worker is exposed.

Why They’re Different from Sound Level Meters

Sound level meters provide instantaneous or short-interval readings at a location. Noise dosimeters travel with the worker, continuously summing exposure (dose and TWA) as conditions change across tasks and areas—ideal for real-world, shift-long assessments.

Core Functions of a Noise Dosimeter

Most professional dosimeters share four core capabilities:

- Continuous measurement with a calibrated microphone near the worker’s ear.

- Exposure calculation for dose, TWA (time-weighted average)et peak level.

- Data logging and storage for later download via USB, Bluetooth, or companion software.

- Threshold alerts when preset exposure or level limits are exceeded.

Calibration and Data Integrity

Each dosimeter should be field-calibrated before and after use with an acoustic calibrator (typically 94 or 114 dB at 1 kHz) to verify accuracy. This step is essential for OSHA/NIOSH compliance and ensures every data point is defensible. After measurement, results are downloaded to software to generate reports for documentation, trend analysis, and hearing conservation planning.

Key Dosimeter Metrics (Quick Reference)

| Metric | What It Represents | Notes |

|---|---|---|

| Dose (%) | Cumulative exposure relative to a criterion level and exchange rate | 100% dose typically corresponds to an 8-hour exposure at the selected standard |

| TWA (dBA) | Average noise level over the measurement period, weighted by duration | Used for OSHA/NIOSH program decisions and documentation |

| Peak / Max (dB) | Highest instantaneous or fast-time-constant level recorded | Helps identify impulsive or impact noise risks |

Best Practices for Noise Dosimeter Use

Following a few best practices helps ensure accurate and audit-ready results. Each step—from setup to data review—contributes to consistency and compliance.

- Place the dosimeter on the shoulder or near the ear on the side most exposed to noise; secure the mic and avoid cable rub.

- Perform pre- and post-use calibration checks to verify accuracy and document both values.

- Keep the microphone clear of clothing, hair, PPE, or wind noise; use windshields when needed.

- Confirm battery life and memory are sufficient for the full monitoring period; verify date/time settings.

- Train workers on proper wearing and handling to prevent tampering, obstruction, or bumps.

- Review logs promptly after collection to confirm completeness and investigate anomalies.

- Store instruments in a clean, dry environment; follow manufacturer maintenance intervals.

- Maintain calibration certificates and exposure records (device serials, exchange rate, weighting, locations) for audits.

These practices help safety teams collect dependable exposure data and maintain confidence in hearing conservation programs. The next section explores the key industries and environments where noise dosimeters provide the greatest value.

Choosing the Right Noise Dosimeter

Selecting the right noise dosimeter ensures your measurements are accurate, compliant, and practical for the environments you monitor.

Different workplaces demand different features—from intrinsic safety in refineries to wireless connectivity for fast reporting—so it’s worth matching the device to your specific use case.

Here are the key factors to consider:

- Intrinsic safety. Required for explosive or hazardous locations. Look for ATEX or IECEx certifications.

- Measurement standards. Verify compliance with OSHA/NIOSH guidance and IEC 61252 performance criteria.

- Form factor. Decide between traditional body-worn units with a cabled mic and compact, cable-free edge dosimeters that mount near the ear.

- Data management. Prioritize USB/Bluetooth connectivity and software integration for reporting, archival, and multi-worker studies.

- Battery life and storage. Ensure enough runtime and memory for full-shift (8–12+ hour) monitoring or multi-day deployments.

- Calibration and QA/QC. Support for pre/post-use field calibration and traceable annual service maintains data integrity.

Types of Noise Dosimeters

Noise dosimeters come in several designs, each suited to specific working conditions and program goals. Understanding the differences helps you choose the right platform for your monitoring strategy.

1. Standard Noise Dosimeters

Traditional body-worn units with a small cabled microphone placed near the ear. They are widely used in industrial hygiene programs and offer robust logging and reporting.

- Strengths. Proven accuracy, flexible mounting, compatible with common calibrators.

- Best for. General industrial surveys, shift-based exposure monitoring, routine compliance work.

2. Edge (Cable-Free) Noise Dosimeters

Compact, shoulder- or helmet-mounted designs that eliminate the microphone cable. Often include wireless connectivity for quick data sync and status checks.

- Strengths. Low profile, reduces snag and handling noise, streamlined workflows.

- Best for. Mobile workers, confined spaces, dynamic jobs with frequent movement.

3. Intrinsically Safe Noise Dosimeters

Models certified for use in explosive atmospheres (ATEX/IECEx). Built for hazardous areas such as oil and gas, chemicals, and mining.

- Strengths. Ignition-proof design, rugged housings, compliance-ready for hazardous locations.

- Best for. Refineries, chemical plants, mines, and other classified areas.

4. Networked / Multi-Person Monitoring Systems

Systems that aggregate readings from multiple dosimeters into a central platform, enabling live dashboards and faster decision-making.

- Strengths. Fleet visibility, trend analysis across crews, real-time alerts.

- Best for. Large facilities, complex turnarounds, ongoing hearing conservation programs.

Noise Dosimeter Selection Overview

| Type | Caractéristiques principales | Best For |

|---|---|---|

| Standard Noise Dosimeter | Full-shift monitoring; cabled mic; local logging; field calibration | General industrial exposure studies and routine compliance work |

| Edge Noise Dosimeter | Compact, cable-free mount; Bluetooth/USB; reduced handling noise | Mobile workers, confined spaces, dynamic jobs with frequent movement |

| Intrinsically Safe Dosimeter | ATEX/IECEx certified; rugged design; hazardous-area compliant | Oil & gas, chemical processing, mining, and classified zones |

7 Industries That Use Noise Dosimeters in Their Work

Because every industry has its own acoustic challenges, noise dosimeters are adapted to a wide range of environments—from confined plants to open construction sites.

Here are seven sectors that regularly use noise dosimeters in their work.

1. Pétrole et gaz

Oil and gas operations generate high sound levels from compressors, pumps, drilling rigs, and process equipment. Noise dosimeters allow HSE teams to quantify worker exposure during exploration, refining, and maintenance activities. The data is essential for ensuring compliance in both hazardous and remote environments.

- Tracking personal exposure near compressors, separators, and flare systems.

- Assessing maintenance crew noise exposure during turnarounds or shutdowns.

- Monitoring drilling and fracking operations for cumulative sound levels.

- Evaluating long-term exposure for field technicians and inspection teams.

2. Power Generation and Utilities

Power plants and utility facilities feature rotating equipment, turbines, and generators that create sustained, high-decibel noise. Personal noise dosimeters measure the exposure of operators, inspectors, and maintenance technicians working in these areas, ensuring regulatory compliance and protecting against hearing loss.

- Measuring exposure in turbine halls, boiler rooms, and transformer areas.

- Monitoring maintenance teams working near steam leaks and pressure valves.

- Assessing exposure during startup, shutdown, and testing operations.

- Documenting compliance for OSHA or internal safety audits.

3. Manufacturing and Fabrication

In manufacturing plants, workers are surrounded by continuous mechanical noise from cutting, stamping, and assembly operations. A noise dosimeter tracks the cumulative exposure of machine operators, welders, and maintenance staff as they move between workstations and equipment lines. This data helps identify when protective controls or quieter machinery are needed.

- Monitoring exposure from CNC machines, presses, and grinders on production floors.

- Evaluating noise during welding, assembly, or quality control tasks.

- Assessing operator exposure in multi-shift or rotating work schedules.

- Verifying compliance with hearing conservation thresholds across departments.

4. Mining and Materials Processing

Mines and processing plants operate heavy machinery that produces extreme, continuous noise. Noise dosimeters provide data on how exposure varies between underground and surface operations, helping safety teams mitigate risk through engineering controls and hearing protection.

- Measuring exposure from crushers, conveyors, and screening systems.

- Tracking underground miner exposure to drilling and ventilation systems.

- Assessing haul truck driver exposure in open-pit operations.

- Supporting compliance with MSHA and OSHA hearing conservation standards.

5. Construction and Heavy Equipment

Construction workers encounter constantly changing noise environments—ranging from power tools and jackhammers to vehicle traffic and generators. Personal noise dosimeters record a worker’s full-shift exposure, giving supervisors accurate data to adjust PPE use and work rotations.

- Tracking exposure to power tools, saws, and pneumatic equipment on job sites.

- Measuring cumulative exposure for equipment operators and truck drivers.

- Recording data across multiple outdoor or indoor projects in a single day.

- Supporting compliance documentation for large infrastructure projects.

6. Transportation and Logistics

Airports, rail terminals, and shipping facilities expose workers to intense, intermittent noise from engines, horns, and mechanical loading systems. Noise dosimeters help employers evaluate exposure for ground crews, mechanics, and cargo handlers who move through dynamic sound environments.

- Monitoring ramp agents and baggage handlers working near jet engines or tugs.

- Evaluating exposure for locomotive engineers and rail yard personnel.

- Assessing forklift and loading dock noise levels in warehouses.

- Validating PPE requirements in distribution centers and logistics hubs.

7. Aerospace and Defense

Aircraft manufacturing and maintenance facilities combine high-intensity noise from engines, tools, and pressurized systems. Noise dosimeters are used to protect technicians and engineers working in hangars, on tarmacs, or in test facilities.

- Recording exposure for aircraft maintenance and ground support crews.

- Monitoring sound levels in test cells and manufacturing bays.

- Evaluating cumulative noise for assembly line or structural technicians.

- Supporting compliance audits for defense and aerospace safety programs.

Workplace Regulations and Compliance

Noise exposure monitoring isn’t just best practice—it’s a regulatory requirement across most industrial workplaces.

This section summarizes the major U.S. and international frameworks that govern occupational noise exposure, including OSHA, NIOSH/ACGIH, and ISO/ANSI/IEC standards for measurement, limits, and documentation. Personal noise dosimeters provide the time-weighted exposure data needed to demonstrate compliance and maintain defensible hearing conservation records.

Key Thresholds at a Glance

| Standard | Metric | Limit | Averaging Period | Authority / Reference |

|---|---|---|---|---|

| OSHA PEL | Permissible Exposure Limit | 90 dBA | 8-hour TWA | 29 CFR 1910.95 |

| OSHA Action Level | Hearing Conservation Program Trigger | 85 dBA | 8-hour TWA | 29 CFR 1910.95 |

| NIOSH REL | Recommended Exposure Limit | 85 dBA (3-dB exchange) | 8-hour TWA | NIOSH Criteria Document |

| ACGIH TLV | Threshold Limit Value | 85 dBA | 8-hour TWA | ACGIH TLVs |

| ISO 9612 | Workplace Noise Assessment | N/A (methods) | Task / full-shift | ISO 9612:2019 |

| IEC 61252 | Dosimeter Performance | N/A (specs) | Instrument standard | IEC 61252 |

OSHA and NIOSH/ACGIH Exposure Limits

OSHA’s Occupational Noise Exposure standard sets a permissible exposure limit (PEL) of 90 dBA as an 8-hour time-weighted average and an action level of 85 dBA. Reaching or exceeding the action level triggers a Hearing Conservation Program with exposure monitoring, employee training, audiometric testing, and recordkeeping requirements.

→ See 29 CFR 1910.95.

A practical rule of thumb: once exposure equals or exceeds an 8-hour TWA of 85 dBA, employers must establish and maintain a hearing conservation program and follow the hierarchy of controls:

- Engineering controls first (source reduction, enclosures, dampening)

- Administrative controls (rotation, scheduling, quiet zones)

- Personal protective equipment (hearing protection) as needed

NIOSH recommends a more protective approach—an 8-hour TWA of 85 dBA using a 3-dB exchange rate—reflected in many corporate policies and ACGIH TLVs. Personal noise dosimeters provide dose, TWA, and peak data that align with these frameworks and support defensible compliance documentation.

ISO and ANSI/IEC Technical References

ISO 9612:2019 defines strategies for assessing occupational noise exposure using task-based or full-shift methods, ensuring consistent sampling plans and reporting.

IEC 61252 specifies performance requirements for personal sound exposure meters (noise dosimeters), including dynamic range, accuracy, and functional tests.

ANSI S1.25 provides U.S. performance requirements for noise dosimeters, complementing IEC specifications and supporting traceable, comparable measurements.

Calibration, Data Integrity, and Audit Readiness

Regulatory decisions rely on traceable, reproducible measurements. Establish calibration and QA/QC routines that make exposure records audit-ready.

- Perform pre- and post-measurement acoustic checks (94 or 114 dB at 1 kHz) and verify readings within ±0.5 dB.

- Maintain calibration certificates, time-stamped logs, and metadata (device serial, worker ID, exchange rate, weighting, locations).

- Inspect microphones, windshields, and clips before deployment; document SOPs and exchange rates (OSHA 5-dB vs. NIOSH 3-dB).

- Schedule annual factory calibration traceable to national standards (e.g., NIST) to preserve long-term data integrity.

Consistent use of professional noise dosimeters—paired with documented calibration and ISO-aligned methods—produces defensible exposure records that meet OSHA requirements and support effective hearing conservation programs.

Noise Dosimeter FAQ

Here are answers to the most commonly asked questions about noise dosimeters.

What is a noise dosimeter used for?

A noise dosimeter is used to measure a worker’s cumulative exposure to noise throughout a shift. It provides time-weighted data that shows whether exposure exceeds OSHA or NIOSH limits. This information helps employers identify high-risk environments and maintain compliance with hearing conservation requirements.

What is the difference between a decibel meter and a noise dosimeter?

A decibel meter, or sound level meter, measures the instantaneous sound pressure level at a specific location and point in time. A noise dosimeter, on the other hand, is worn by an individual and measures total exposure over several hours. Sound level meters are great for quick checks, while dosimeters provide a complete picture of personal exposure.

Can I measure noise level with my phone?

Smartphone apps can provide a general indication of sound levels, but they are not accurate enough for compliance measurements. Phones lack the calibrated microphones and precision circuitry required by OSHA and NIOSH standards. For workplace monitoring and reporting, a professional noise dosimeter or sound level meter is required.

How does a noise dosimeter measure exposure?

Noise dosimeters use a small microphone to detect sound pressure levels continuously over time. The instrument calculates exposure based on both intensity and duration, producing metrics such as dose, time-weighted average (TWA), and peak levels. These values help determine whether protective controls or hearing protection are needed.

How often should a noise dosimeter be calibrated?

A noise dosimeter should be calibrated before and after every measurement session to ensure accuracy. Routine calibration checks verify that the microphone and sensors are performing correctly and that readings are traceable to a known reference tone. Annual laboratory calibration is also recommended to maintain compliance with industry standards.

What does OSHA require for noise exposure monitoring?

OSHA’s Occupational Noise Exposure Standard (29 CFR 1910.95) requires employers to measure and control employee noise exposure when levels exceed an 8-hour time-weighted average of 85 decibels. Personal noise dosimeters are the preferred tool for these measurements, as they capture data directly from the worker’s perspective.

What is an intrinsically safe noise dosimeter?

An intrinsically safe noise dosimeter is designed for use in hazardous environments such as oil refineries, chemical plants, and mines. These models are built to prevent sparks or heat generation that could ignite flammable gases or dust. They meet international safety certifications like ATEX or IECEx for explosive atmospheres.

What’s the difference between a personal noise dosimeter and a sound level meter?

A personal noise dosimeter measures the noise exposure experienced by an individual worker, while a sound level meter measures ambient noise in a specific area. Dosimeters provide continuous, shift-long monitoring, whereas sound level meters are typically used for spot measurements or area surveys.

What is an edge noise dosimeter?

An edge noise dosimeter refers to a compact, wearable model designed for comfort and mobility. These lightweight units clip onto the shoulder or helmet, making them ideal for workers who move frequently or work in confined spaces. Despite their small size, they offer the same accuracy and functionality as full-sized dosimeters.

How long should a noise dosimeter be worn?

A noise dosimeter is typically worn for the full duration of a worker’s shift—usually eight hours—to capture representative exposure data. In some cases, shorter sampling periods are acceptable if noise levels are consistent throughout the day. Continuous monitoring ensures the most accurate picture of total daily exposure.

For more information on professional noise monitoring tools, explore MFE’s full range of dosimeters, sound level meters, and acoustic imagers.