Ressources / Étude de cas / MFE Supports Acuren in Pioneering Drone-Based BIM Modeling at Sea

Étude de cas

MFE Supports Acuren in Pioneering Drone-Based BIM Modeling at Sea

When a maritime client needed accurate surface area calculations to plan paint orders for over 60 ballast tanks, it turned to Acuren. To deliver on the challenge, Acuren turned to MFE Inspection Solutions. Together, they developed a new workflow using drone-based LiDAR to create highly accurate building information models (BIM)—a first-of-its-kind approach that solved a problem no other provider had been able to crack.

Avantages

Precise, Accurate Drone-Based BIM Models

First-of-Its-Kind Workflow

Reduced Cost Risk

Introduction

When a maritime client needed precise surface area calculations to plan paint orders for ballast tanks on a 500-foot vessel, it turned to Acuren.

With the ship scheduled to be at sea for up to eight months at a time, the margin for error was slim. Too much paint would mean wasted product and budget, while too little could delay vital maintenance far from shore.

The scale and complexity of the task made it unusually hard. Over 60 tanks and compartments would need to be modeled in 3D—and with a level of accuracy never before achieved.

Le défi

The client had already exhausted several avenues for calculating surface area in the tanks:

- As-built plans were unreliable. The ship’s as-built plans couldn’t be used for the calculations because the tanks had been modified over time with extra piping, stairs, and other structures, changing their overall surface area.

- Manual data collection didn’t work. Taking measurements manually couldn’t provide the accuracy required, and would also take far too long to be practical.

- Drones had also failed. Using drone-based LiDAR with common software solutions also didn’t work—two other providers had tried and failed to produce the level of accuracy the client needed.

To succeed, the client needed a partner willing to go beyond standard approaches and develop a new way of using drone-based LiDAR to calculate internal surface area.

La solution

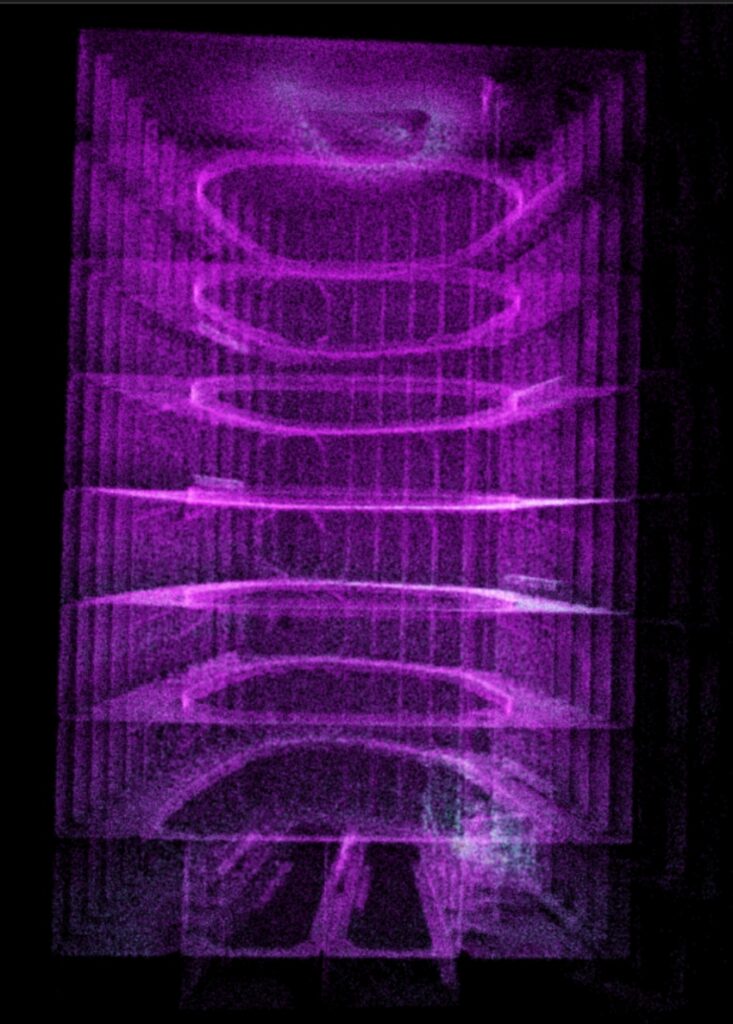

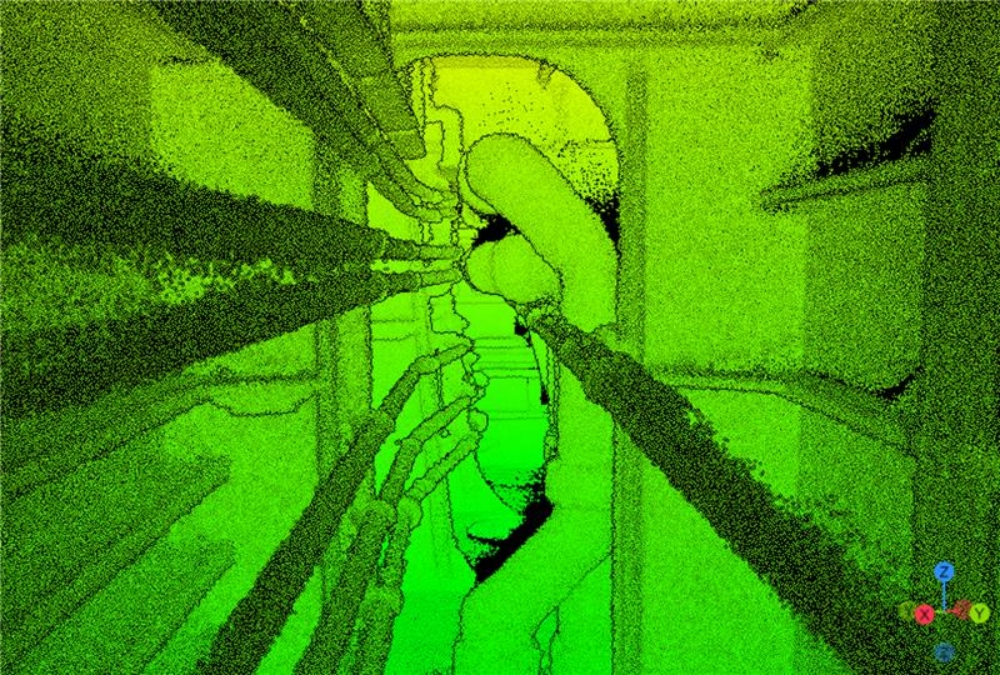

To tackle the challenge, Acuren turned to the Elios 3 drone equipped with Ouster’s Rev 7 survey-grade LiDAR sensor. Built for confined spaces like ballast tanks, the Elios 3 carries a protective cage and uses advanced collision-avoidance algorithms, allowing it to operate safely in cluttered, GPS-denied environments.

The Rev 7 LiDAR provided denser, more precise point clouds than the standard Rev 6, capturing 644,640 extra data points per second to map the vessel’s complex geometries.

MFE Inspection Solutions played a key role in making the mission possible. When Acuren needed an additional Elios 3 at short notice, MFE overnighted a replacement, keeping the project on track.

“We were only able to succeed with MFE’s support. They helped us connect with the client, secured the extra equipment we needed, and even overnighted an Elios 3 when all of ours were deployed. That level of partnership made the difference.”

Lucas Light, Regional Drone Operations Manager at Acuren

Beyond equipment, MFE provided technical guidance and coordination, ensuring Acuren had the resources and connections required to deliver the results its client needed.

The Workflow that Changed Everything

It took the Acuren team a week on the ship to collect all the LiDAR data needed to create 3D maps of the 60+ ballast tanks.

But collecting data was the easy part. The real challenge was producing the calculations the client needed.

Here’s the first workflow Acuren tried:

- Step 1—Aligning scans. Acuren processed the LiDAR data in FaroConnect to align the point clouds and prepare them for modeling.

- Step 2—Generating meshes. Acuren imported the aligned data into Leica Cyclone 3DR for automated mesh generation.

On paper, this approach was promising.

But in practice, the workflow dramatically overestimated surface areas, producing outputs riddled with holes, overlaps, and inaccuracies. These meshes proved to be far too inaccurate to meet the client’s needs, despite dozens of hours invested in making them.

At this point, past providers had given up. But Acuren kept pushing.

To find a solution, the project became a genuine group effort. Acuren’s geospatial data acquisition manager drew on his LiDAR expertise, MFE helped troubleshoot equipment and workflow challenges, Flyability provided direct support on the LiDAR sensor, and Leica Cyclone 3DR partners advised on modeling tools.

Together, the Acuren team refined a process that had never been attempted successfully before:

- Step 1—Abandoning automation. After finding major inaccuracies in the auto-mesh models, the team set aside automated workflows in favor of a more manual process.

- Step 2—Extruding surfaces. Instead of relying on mesh generation, surfaces were manually extruded directly from the point clouds to capture the true geometry of each tank.

- Step 3—Validating accuracy. The manually created BIM models were cross-checked against the client’s hand measurements, confirming their reliability for calculating surface areas.

“Other providers had tried and walked away, but we kept pushing. It took weeks of trial and error, working with software partners and Flyability, to finally create a workflow that delivered the accuracy the client needed.”

Lucas Light, Regional Drone Operations Manager at Acuren

Les résultats

The new approach worked.

After over a hundred hours of troubleshooting, Acuren delivered what no other provider had achieved for the client: highly accurate BIM models generated from drone-based LiDAR inside a complex maritime vessel.

The breakthrough came when the team shifted from relying on automated mesh generation to manually extruding surfaces from the point cloud.

The effort paid off. The surface measurements from the new 3D model matched hand measurements the client had taken, giving them confidence that the data could be trusted.

Principaux résultats :

- Accurate BIM models. Drone-based Rev 7 LiDAR data produced precise models of the vessel’s complex interiors.

- Précision validée. Models aligned with the client’s hand measurements, confirming reliability.

- Trusted surface area calculations. Provided the numbers needed to plan paint orders with confidence.

- Proven workflow. Established the first successful real-world method for turning drone-based LiDAR into BIM models.

Conclusion: A Blueprint for Future Surface Area Calculations

The success of this project showed what’s possible when persistence, collaboration, and the right technology come together. By delivering accurate BIM models from drone-based LiDAR inside a maritime vessel, Acuren achieved something no other provider had.

MFE’s role was critical. From securing additional equipment at short notice to facilitating connections with Flyability and offering hands-on technical support, MFE ensured Acuren had the resources and backing needed to push through obstacles and refine a brand-new workflow.

But the result wasn’t just a technical success. It was a demonstration of the value of strong partnerships in solving complex challenges.

This project also proves a broader point: innovation doesn’t always require new tools—it often comes from finding new ways to use the tools we already have.

With MFE’s support, Acuren has set a precedent for future maritime inspections and is preparing to repeat the process for more ships.

Before long, the workflow may be scaled across the client’s entire fleet, paving the way for broader adoption in the maritime industry and beyond.

Partager