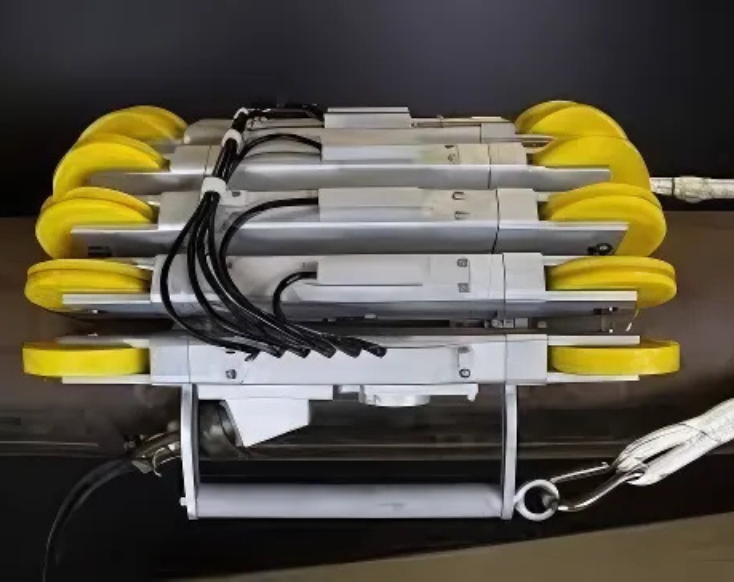

The MFE PipeScan is a rugged, easy-to-use Magnetic Flux Leakage (MFL) inspection tool built to quickly and accurately detect corrosion and defects in pipelines—think of it as a metal detector for your pipe’s health. Delivering real-time digital feedback with adjustable alarms, it ensures inspectors are only alerted when it truly matters.

Engineered for field flexibility, this MFL pipe scanner can scan through protective coatings and adapt to a wide range of pipe sizes and inspection needs without extensive prep work. Ideal for industries that depend on pipeline infrastructure, the MFE PipeScan helps inspection teams save time, improve accuracy, and make smarter maintenance decisions.

Equipment Type: MFL Pipe Scanner

Request a Quote

The MFE PipeScan is engineered for precision, speed, and durability—everything you need for efficient pipeline integrity assessments. Using Magnetic Flux Leakage technology, it detects corrosion and other hidden defects without disrupting operations.

Designed for industrial environments and real-world conditions, the MFE PipeScan combines real-time data visualization with a rugged, user-friendly design, helping teams reduce downtime, increase safety, and make informed maintenance decisions with confidence.

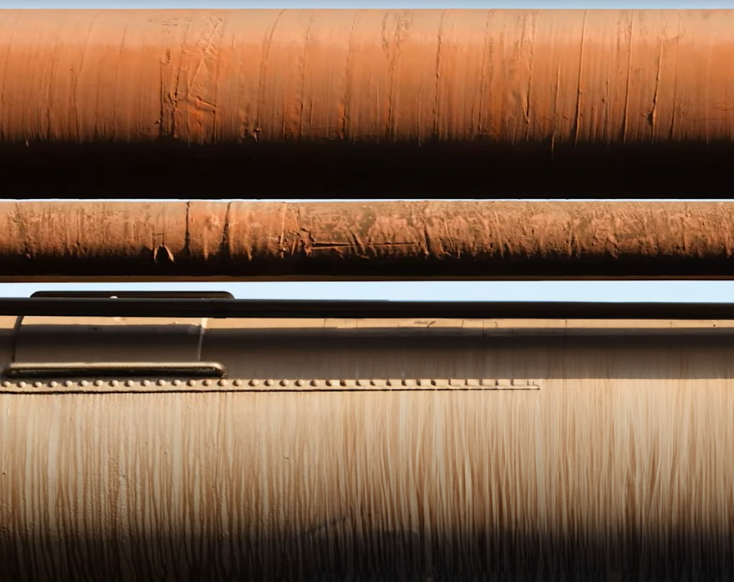

The MFE PipeScan adapts to pipelines of nearly any size, scanning diameters starting at 5 inches with no maximum limit.

Each pass delivers a 7.5-inch inspection width at speeds of up to 3 feet per second, allowing inspectors to cover large sections quickly and with confidence.

By accommodating a broad range of pipe sizes, the MFE PipeScan streamlines inspections and helps teams work more efficiently in the field.

Designed to keep inspections moving, the MFE PipeScan operates at speeds of up to 3 feet per second, covering more ground in less time.

Operators see corrosion signals instantly through the integrated Getac F110 tablet, which displays real-time digital volume loss data during every scan.

This combination of speed and live feedback enables inspection teams to detect issues quickly, stay on schedule, and act on reliable data without delay.

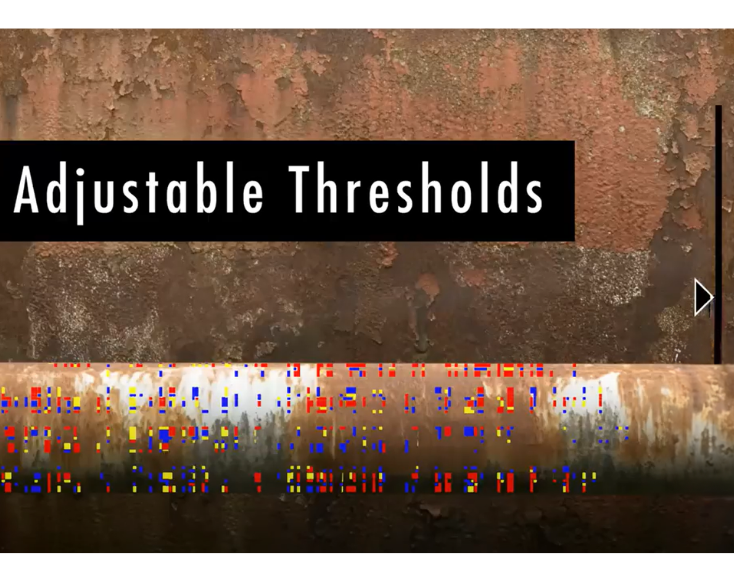

The MFE PipeScan gives operators full control over inspection sensitivity with adjustable gain and alarms.

Thresholds can be tailored to match specific applications, ensuring alerts only trigger when a true defect is found. This precision not only saves time but also helps reduce false positives, letting inspectors focus on what matters most.

A freeze screen alarm feature adds extra flexibility, allowing teams to pause and review signals on the spot.

Pipelines don’t have to be stripped before inspection, the MFE PipeScan can scan through non-magnetic coatings up to 12 mm (0.5 inches) thick.

By eliminating the need for coating removal, inspection teams can save significant time and labor while still capturing accurate data on pipeline integrity.

This capability makes inspections faster, more efficient, and far less disruptive to operations.

The MFE PipeScan goes beyond scanning, it’s built as a complete inspection solution. Outfitted with field-ready components like the Getac F110 tablet, a 50+ foot signal cable, and the MFE electronics module, it keeps inspections running smoothly with minimal downtime.

Once data is collected, Scan Studio software transforms results into corrosion maps, technical drawings, and shareable reports, while also allowing integration with other NDT methods for a more complete picture of pipeline integrity.

Ready to streamline your inspections and take reporting to the next level? Contact MFE Inspection Solutions today to learn how the MFE PipeScan can transform your pipeline integrity program.

| Magnetic System | Rare earth magnets in magnetic bridge for area saturation |

| Detection System | Sensor array across the scanning head detects magnetic flux leakage |

| Approx. Weight | 35 lbs |

| Weight per MFL Bridge | 5.25 lbs |

| Control Unit | Getac F110 Tablet (touchscreen) |

| Pipe Diameter Compatibility | 5 inches and up, no maximum limit |

| Inspection Area (Single Pass) | 7.5 inches |

| Scanning Speed | Up to 3 feet per second |

| Coating Penetration | Yes, scans through non-magnetic coatings |

| Max Coating Thickness | Up to 12 mm (0.50 inches) |

| Power Source | Battery pack |

| Electronics Module | MFE Electronics Module |

| Signal Cable Length | 50+ feet |

| Software Integration | Compatible with Scan Studio software |

| Reporting | Exportable to PDF for fast, easy-to-view reports |