Guide

PMI Guns: Your Guide to the Top XRF Analyzers on the Market

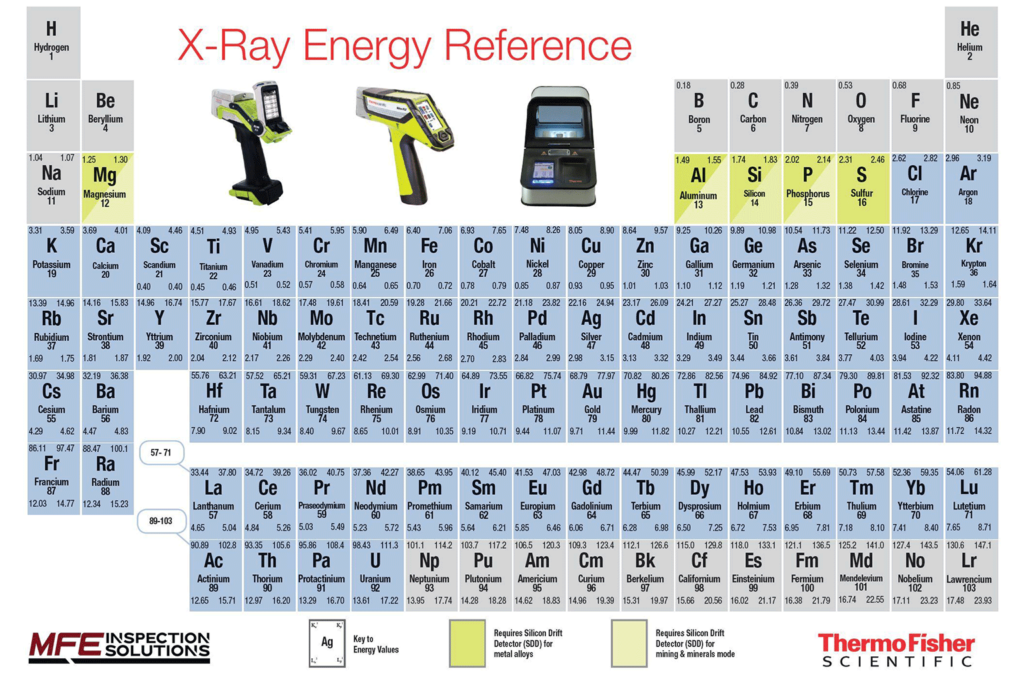

A PMI gun—also called an XRF analyzer—is a portable device equipped with X-ray fluorescence technology. It allows for non-destructive testing, ensuring materials meet stringent industry standards and specifications.

→ Jump to the best PMI guns and XRF analyzers of 2026.

In industrial inspections, Positive Material Identification (PMI) plays a critical role in verifying metal alloys’ composition and quality.

In layman’s terms, a PMI gun is like a magic wand that can tell you what any metal is made of by just pointing at it and zapping it with a special light. It helps people make sure they’re using the right kind of metal for things like airplanes, bridges, and toys, so everything is safe and works like it should.

Other common terms for a PMI gun include:

- XRF analyzer

- Handheld XRF (X-ray fluorescence) analyzer

- Portable XRF analyzer

- Material analyzer

- Alloy analyzer

- Metal analyzer

The first three terms—the ones that have XRF in them—are used generally to refer to a PMI gun. The latter three terms refer to a PMI gun when it’s being used for a specific application, like analyzing alloys or metals.

PMI Gun Rentals and Sales

Want to buy or rent a PMI gun? Keep reading to see the top options on the market.

Note: All our XRF analyzers are manufactured by our trusted partner Thermo Fisher Scientific, the makers of Niton PMI equipment. Thermo Fisher Scientific is a leading provider of analytical instruments and scientific equipment, and their Niton analyzers are among the most recognized PMI devices on the market.

1. Thermo Scientific Niton XL2 800 PMI Gun

The Thermo Scientific Niton XL2 800 PMI Gun is a handheld X-Ray Fluorescence (XRF) scanner designed for robust and dependable elemental analysis in various inspection needs, including harsh and dirty environments.

Its lightweight design makes it user-friendly, even for non-technical personnel, while its ergonomic build and clear touchscreen display ensure it can be used in any lighting condition, including bright daylight. This PMI gun is a reliable tool for fast and accurate elemental analysis in any location and application, from metal and alloy analysis to mining, exploration, and even consumer goods inspections. Key features of the Niton XL2 800:

- Dependable elemental analysis. Provides reliable analysis for demanding inspection requirements.

- User-friendly interface. Features an easy-to-use, clear touchscreen display suitable for all lighting conditions.

- Customizable software. Onboard software customization is possible, with multi-language support and capabilities expansion via Niton Data Transfer software for setting permissions, generating reports, and remote operation.

2. Niton XL5 Plus Handheld XRF Analyzer

The Thermo Scientific Niton XL5 Plus is known for being the smallest, lightest elemental XRF analyzer available. Its portability significantly reduces operator fatigue, especially in tight or hard-to-reach spaces. The XL5 Plus is built for durability, designed to withstand harsh environments, which makes it ideal for various industrial applications. Also, its advanced features not only provide low detection limits and fast analysis times but also offer the flexibility to test a vast array of materials with a single analyzer, making it a valuable tool for industries relying on precise elemental analysis and material identification. Key features of the Niton XL5 Plus:

The Thermo Scientific Niton XL5 Plus is known for being the smallest, lightest elemental XRF analyzer available. Its portability significantly reduces operator fatigue, especially in tight or hard-to-reach spaces. The XL5 Plus is built for durability, designed to withstand harsh environments, which makes it ideal for various industrial applications. Also, its advanced features not only provide low detection limits and fast analysis times but also offer the flexibility to test a vast array of materials with a single analyzer, making it a valuable tool for industries relying on precise elemental analysis and material identification. Key features of the Niton XL5 Plus:

- Advanced technology. Equipped with a 5W X-ray tube and a large area drift detector for enhanced light element detection, ensuring precise and rapid results.

- Enhanced durability. The device is splash-proof and dust-tight, with added protection for its detector, making it suitable for rugged use in challenging conditions.

- User-friendly design. Features directional keys and a miniaturized nose for improved accessibility and ease of use. Additionally, it’s WiFi-enabled and supports hot-swap battery functionality for uninterrupted usage.

- Imaging capabilities. Includes both macro and micro cameras for detailed visual documentation of the analysis area.

- Customizable and secure. Offers password-protected security and allows for customization of data captures and user profiles to suit specific workflow requirements.

3. Niton XL3t 800 XRF Analyzer

The Thermo Scientific Niton XL3t is a sophisticated PMI gun designed for nondestructive testing, offering quick results for metal analysis, mining, exploration, and even lead paint testing for consumer goods. Its portability and efficiency make it ideal for a variety of applications, including scrap metal recycling, manufacturing quality assurance and control (QA/QC), and positive material identification (PMI). This XRF analyzer is especially valuable for real-time compliance testing in adherence to regulations such as CPSIA, Proposition 65, RoHS, and others. Key Features of the Niton XL3t include:

The Thermo Scientific Niton XL3t is a sophisticated PMI gun designed for nondestructive testing, offering quick results for metal analysis, mining, exploration, and even lead paint testing for consumer goods. Its portability and efficiency make it ideal for a variety of applications, including scrap metal recycling, manufacturing quality assurance and control (QA/QC), and positive material identification (PMI). This XRF analyzer is especially valuable for real-time compliance testing in adherence to regulations such as CPSIA, Proposition 65, RoHS, and others. Key Features of the Niton XL3t include:

- High-performance detector. Utilizes a high-performance semiconductor detector for precise analysis.

- Advanced tube technology. Equipped with an Au anode tube capable of reaching 50kV and 200μA, enabling lower detection limits and higher accuracy.

- Versatile applications. Designed for a broad range of uses from alloy analysis to environmental testing, with specific modes for metals, soils, and more.

- User-friendly interface. Features an adjustable angle, color, touch-screen display for ease of use in various conditions.

4. Niton XL3t 980 GOLDD+ Handheld XRF Analyzer

The Thermo Scientific Niton XL3t 980 GOLDD+ is an advanced handheld XRF analyzer designed for a broad range of applications, leveraging high-end technology to deliver rapid, accurate elemental analysis. This PMI gun is named for its use of GOLDD+ technology, which gives it an enhanced ability to analyze light elements like magnesium, aluminum, silicon, phosphorus, and sulfur without the need for helium purging or vacuum pumps, making it exceptionally versatile and efficient for on-site analysis. The Niton XL3t GOLDD+ model further enhances these capabilities with GOLDD technology for improved light element (Mg-S) analysis, offering the lowest limits of detection and the fastest measurement times. Its ability to deliver lab-quality results in a portable format makes it a valuable tool for professionals who require high precision and efficiency in their operations. Key features of the Niton XL3t 980 GOLDD+:

The Thermo Scientific Niton XL3t 980 GOLDD+ is an advanced handheld XRF analyzer designed for a broad range of applications, leveraging high-end technology to deliver rapid, accurate elemental analysis. This PMI gun is named for its use of GOLDD+ technology, which gives it an enhanced ability to analyze light elements like magnesium, aluminum, silicon, phosphorus, and sulfur without the need for helium purging or vacuum pumps, making it exceptionally versatile and efficient for on-site analysis. The Niton XL3t GOLDD+ model further enhances these capabilities with GOLDD technology for improved light element (Mg-S) analysis, offering the lowest limits of detection and the fastest measurement times. Its ability to deliver lab-quality results in a portable format makes it a valuable tool for professionals who require high precision and efficiency in their operations. Key features of the Niton XL3t 980 GOLDD+:

- GOLDD+ technology. Offers improved sensitivity for light elements, providing lower limits of detection and faster measurement times compared to conventional XRF analyzers.

- Comprehensive analytical range. Capable of analyzing up to 30 elements from magnesium to uranium, varying by application, making it suitable for a wide array of material types.

- Enhanced productivity. Equipped with features such as a tilting, color, touch-screen display; integrated cameras for precise sample imaging; and hot-swap battery functionality to minimize downtime.

- Robust design. Built for durability and compliance in harsh industrial environments, ensuring reliable performance in the field.

Rent the Niton XL3t 980 GOLDD+.

PMI Training

We offer advanced PMI training with experts from ThermoFisher’s Niton, makers of the top PMI equipment on the market. Our Advanced PMI Course covers:

Our Advanced PMI Course covers:

- All aspects of Positive Material Identification (PMI) alloy training

- Hydrofluoric Acid (HF) Alky service

- Low Residual Element (LRF) material to carbon content on L&H grade stainless steel

Details:

- The training is three days long

- The training is taught by level III Technicians from Niton, who have over 30 combined years in the field

- Students who complete the training receive a certification on behalf of ThermoFisher and MFE Inspection Solutions

Types of training:

- Group training. Individual students join a scheduled class for a group training.

- Personalized training. Companies schedule their own personalized training for their employees (requires 3 or more students).

View our upcoming PMI training sessions now.

How a PMI Gun Works

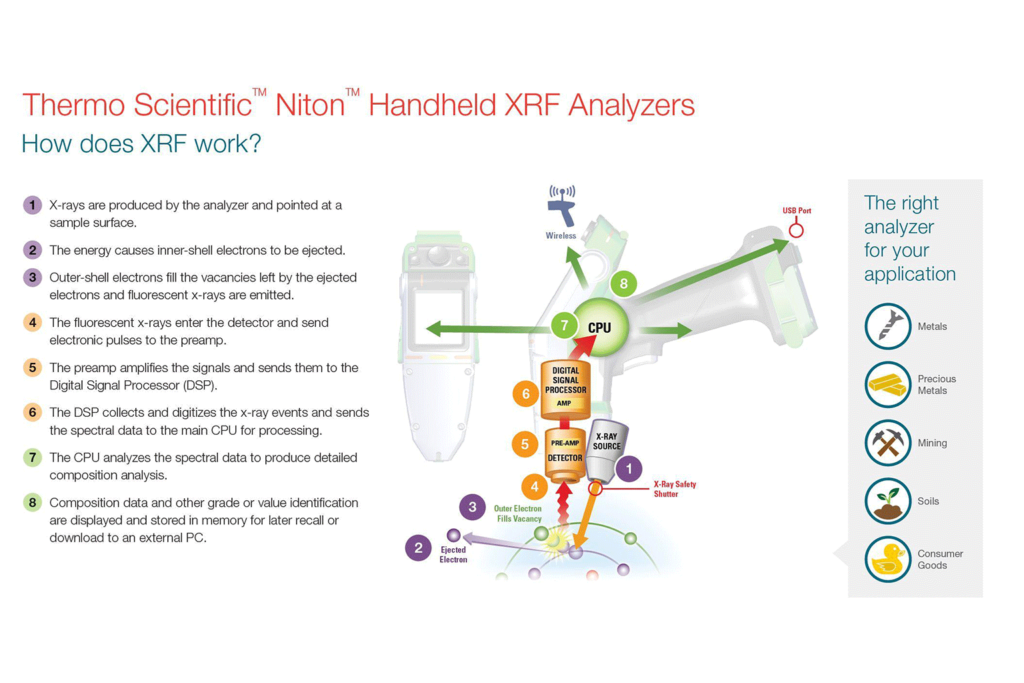

A PMI gun operates using X-ray Fluorescence (XRF) technology, which is a non-destructive analytical technique. When the gun is pointed at a material, it emits X-rays that interact with the atoms in the material.

This interaction causes the atoms to emit secondary X-rays, which are characteristic of the specific elements they represent. The PMI gun detects these secondary X-rays and analyzes their energy spectra to identify and quantify the material’s elemental composition.

This rapid and accurate process allows for on-site verification of metal alloys, ensuring they comply with required specifications without damaging the material. Want a little more information?

Here’s a short step-by-step to walk you through how a PMI gun works:

- Emission of X-rays. The PMI gun emits primary X-rays towards the material being tested, which penetrate the surface.

- Interaction with atoms. These X-rays interact with the atoms in the material, displacing electrons from their orbits and causing the atoms to become excited.

- Emission of secondary X-rays. As the atoms return to their stable state, they emit secondary (or fluorescent) X-rays, characteristic of the specific elements present in the material.

- Detection. The PMI gun’s detector captures these fluorescent X-rays and measures their energy spectra.

- Analysis. The device analyzes the energy spectra to identify and quantify the elemental composition of the material.

- Result display. The identified elements and their concentrations are displayed, providing immediate insight into the material’s composition.

So what’s next? That is, after you get the findings from a PMI gun, what do you do with them? After obtaining the elemental composition from a PMI gun, the findings are used to verify material specifications against industry standards or specific project requirements.

This ensures that materials are correctly identified and suitable for their intended application, preventing potential failures or non-compliance issues. Essentially, the results guide material selection, quality control, and compliance processes, ensuring safety and reliability in various applications.

Learn more about our Advanced PMI training to help you get the most out of your PMI equipment’s findings.

The Top 10 Applications for PMI Guns

How do people actually use PMI guns in the field? Here are the top ten ways.

1. Mining

PMI guns are an indispensable mining tool, helping to ensure the quality and composition of mined materials. These portable devices are used directly at the mining site to quickly and accurately analyze ore samples and other geological materials. Common mining uses for XRF analyzers:

- Process evaluations. Support in determining the best processing methods.

- Ore grade assessment. Determining the composition and quality of ore.

- Mineral Identification. Assessing ore grades and identifying valuable minerals for extraction.

Benefits to mining operations:

- Savings. Reduce costs associated with sending samples to off-site laboratories

- Safety and compliance. Ensuring that materials such as the structural steel used in mining equipment and infrastructure meet specified standards, thereby preventing failures and accidents

- Efficiency. Streamlining the mining process by quickly assessing ore quality, helping make immediate decisions about the viability of mining specific areas

2. Oil & Gas Industry

XRF analyzers are critical for maintaining operational safety, efficiency, and regulatory compliance in the oil and gas industry. By facilitating the rapid identification of alloys and the detection of potentially hazardous materials, PMI guns play a vital role in upholding the integrity and reliability of oil and gas operations worldwide. Common Oil & Gas uses for XRF analyzers:

- On-site analysis. Real-time analysis of pipelines, valves, fittings, and other components crucial to the extraction, transportation, and processing of oil and gas.

- Quality control. Aid in quality control during the manufacturing and assembly phases.

- Pipeline inspections. Ensuring pipeline materials resist corrosion.

- Equipment verification. Confirming the material composition of drilling and processing equipment.

Benefits to Oil & Gas operations:

- Quality control. Ensuring that all parts meet stringent industry standards and specifications

- Safety and reliability. Enhancing infrastructure safety and operational reliability.

- Compliance. Ensuring adherence to industry standards and regulations, thereby avoiding accidents, fines, and operational shutdowns

3. Power Generation

In the power generation industry, PMI guns are essential for ensuring the safety and efficiency of power plants, whether they are nuclear, hydroelectric, coal-fired, or renewable energy facilities. XRF analyzers devices facilitate the rapid, non-destructive testing of critical components, verifying that the materials used can withstand the extreme conditions of power generation, including high temperatures, pressures, and corrosive environments. Common Power Generation uses for XRF analyzers:

- Component analysis. Verifying the alloy composition of critical components.

- Corrosion monitoring. Assessing materials for corrosion to prevent failures.

- Compliance. Ensuring materials meet industry and safety standards.

Benefits to Power Generation operations:

- Safety assurance. Enhancing the reliability and safety of power generation facilities.

- Operational efficiency. Reducing downtime by identifying material issues promptly.

- Compliance. Helping adhere to strict industry regulations.

4. Pharmaceutical & Chemical Industries

In the pharmaceutical and chemical industries, XRF analyzers are important tools for upholding the purity of products and the safety of manufacturing processes. Both industries demand rigorous compliance with material standards to prevent any risk of contamination that could compromise the efficacy and safety of pharmaceutical products and chemical compounds. PMI guns provide a swift and non-invasive means to verify the composition of key production apparatus, such as reactors, pipelines, and storage tanks, ensuring they conform to the stringent requirements essential for high-quality manufacturing. Common Pharmaceutical and Chemical uses for XRF analyzers:

- Material verification. Confirming the composition of materials to prevent contamination.

- Quality assurance. Monitoring production equipment to maintain process integrity.

- Compliance. Ensuring adherence to strict industry standards and regulations.

Benefits to Pharmaceutical and Chemical operations:

- Enhanced product safety. Preventing contamination and ensuring product integrity.

- Operational efficiency. Streamlining material verification to minimize production delays.

- Regulatory adherence. Meeting the stringent requirements of regulatory bodies.

5. Construction & Infrastructure

In the realm of construction and infrastructure, PMI guns serve as critical instruments to ensure the structural integrity and longevity of various projects. These handheld devices facilitate the swift, on-site analysis of metal components such as beams, pipes, and connectors, verifying that they align with the requisite standards and specifications. XRF analyzers not only aid in the initial construction phase but are also invaluable during renovation and retrofitting projects because they offer a non-invasive method to identify the composition of existing structures, ensuring compatibility and safety during upgrades. Common Construction & Infrastructure uses for XRF analyzers:

- Material verification. Ensuring the correct grade and composition of structural materials.

- Quality control. Confirming consistency and quality of materials throughout the construction process.

- Compliance checks. Verifying materials comply with building codes and safety regulations.

Benefits to Construction & Infrastructure operations:

- Risk mitigation. Reducing the likelihood of structural failures by ensuring material integrity.

- Project efficiency. Minimizing delays associated with material testing, adhering to project schedules and budgets.

- Compliance. Supporting adherence to local and international construction standards, enhancing overall project quality.

6. Metal and Alloy Analysis

PMI guns are indispensable in the field of metal and alloy analysis, offering a quick and accurate way to make material composition determinations. This is particularly essential in sectors like manufacturing, aerospace, automotive, and construction, where the structural integrity and functionality of metal components are critical. Through immediate on-site analysis, PMI guns allow for the identification and quantification of various elements within metals and alloys, ensuring they meet the rigorous standards for strength, durability, and corrosion resistance necessary for their specific uses. PMI guns thus play a vital role in maintaining quality control, enhancing production efficiency, and ensuring compliance within the metal and alloy analysis domain. Their non-destructive testing capability not only safeguards operational continuity but also supports the advancement of material science, contributing to the development of safer, more durable, and innovative metal products and structures. Key applications in Metal and Alloy Analysis for XRF analyzers:

- Material verification. Rapid confirmation of metal grades and compositions to prevent material mix-ups.

- Quality assurance. Continuous monitoring throughout the manufacturing process to ensure product consistency and integrity.

- Compliance and certification. Verification that materials conform to industry standards and regulatory requirements.

Benefits for Metal and Alloy Analysis:

- Enhanced safety and reliability. Ensuring materials meet required specifications reduces the risk of component failure, enhancing overall safety and product reliability.

- Operational efficiency. The ability to perform analyses on the spot eliminates the need for costly and time-consuming laboratory testing, thereby minimizing production delays.

- Innovation support. PMI guns are valuable in research and development, aiding in the formulation of new alloys and the enhancement of existing materials, driving innovation within the industry.

7. Aerospace & Aviation

In the demanding realm of aerospace and aviation, PMI guns are vital for safeguarding the safety and dependability of aircraft components. These handheld devices enable the non-invasive examination of essential parts, ranging from engine mechanisms to the structural framework, ensuring they comply with rigorous aerospace standards. The capacity for immediate, on-site alloy analysis with PMI guns is instrumental in preventing material discrepancies, confirming that components can endure the severe pressures and temperatures characteristic of aviation environments. Common Aerospace & Aviation uses for XRF analyzers:

- Component certification. Verification that parts meet aerospace material specifications for safety and performance.

- Maintenance and repair. Assessment of aircraft components during routine maintenance and after repairs to ensure ongoing reliability.

- Failure analysis. Investigation of component failures to identify material flaws or deviations from specifications.

Benefits to Aerospace & Aviation operations:

- Enhanced aircraft safety. By guaranteeing material integrity, PMI guns contribute significantly to the overall safety and functionality of aircraft, directly impacting passenger and crew well-being.

- Operational integrity. Ensures the reliability of aircraft components over time, supporting the longevity and performance of the fleet.

- Regulatory compliance. Facilitates adherence to international aviation standards and regulations, ensuring that aircraft meet global safety and quality benchmarks.

8. Metal Recycling

In metal recycling, PMI guns play a key role in enhancing operational workflows and ensuring the integrity of recycled materials. These portable analyzers enable the immediate identification of diverse metals and alloys in scrap heaps, streamlining the sorting and processing stages. By pinpointing the exact composition of recycled metals, PMI guns empower recyclers to prevent batch contamination, a crucial aspect in preserving the quality and market value of recycled outputs. Common applications in Metal Recycling for XRF analyzers:

- Material identification. Rapidly distinguishes between various types of scrap metal, facilitating effective sorting.

- Quality control. Ensures the purity of recycled batches, avoiding the mixing of incompatible or undesirable materials.

- Compliance and certification. Verifies that recycled metals meet the specific standards required by downstream industries.

Benefits for Metal Recycling operations:

- Increased efficiency. The ability to perform on-the-spot metal analysis reduces dependency on external laboratories, speeding up the recycling process.

- Economic sustainability. By optimizing sorting and processing, PMI guns enhance the profitability of recycling operations, turning scrap into valuable resources.

- Environmental impact. Supports sustainability efforts by maximizing the reuse of materials, reducing waste, and minimizing the environmental footprint of metal production.

9. Manufacturing & Fabrication

PMI guns are crucial for ensuring the caliber and uniformity of end products in the manufacturing and fabrication sector. These devices offer instantaneous, non-invasive evaluations of materials, affirming that the utilized alloys align with prescribed specifications—key for sectors where the characteristics of materials, such as their strength, resistance to corrosion, and electrical conductivity, are integral to a product’s functionality and safety. Common Manufacturing & Fabrication for XRF analyzers:

- Material verification. Swift validation of alloy compositions to prevent the use of incorrect materials.

- Quality control. Continuous monitoring throughout the production cycle to ensure the consistency and quality of products.

- Standards compliance. Assurance that products meet or exceed industry-specific standards and regulations.

Benefits to Manufacturing & Fabrication operations:

- Prevention of errors. Mitigates the risk of costly errors and material misidentification, thus averting potential product failures and recalls.

- Reliability enhancement. Incorporating PMI guns into quality assurance practices bolsters product dependability, meeting and surpassing industry norms and customer anticipations.

- Efficiency and waste reduction. The capacity for on-site verification expedites the production process, minimizes material wastage, and upholds the integrity of manufacturing operations.

10. Toys & Consumer Goods

In the realm of toys and consumer goods manufacturing, PMI guns play a crucial role in safeguarding product safety and ensuring adherence to regulatory standards. The ability of PMI guns to perform immediate analysis on materials like plastics, metals, and ceramics used in toys, jewelry, and electronic goods means that manufacturers and quality assurance teams can quickly verify compliance with safety regulations. XRF analyzers help in the rapid detection of restricted hazardous substances, such as lead, cadmium, and other heavy metals, which are particularly concerning in products intended for children. By enabling quick and accurate material verification, PMI guns assist manufacturers in delivering products that are not only innovative and engaging but also safe and trustworthy, thereby supporting the industry’s commitment to consumer well-being. Common Toys and Consumer Goods uses for XRF analyzers:

- Hazardous substance detection. Identifying the presence of restricted materials to ensure consumer safety.

- Regulatory compliance. Ensuring products meet the safety standards set by organizations like the CPSC and other international regulatory bodies.

- Quality assurance. Maintaining consistent product safety standards across manufacturing batches.

Benefits for Toys and Consumer Goods operations:

- Consumer safety. Protects the most vulnerable consumers, such as children, from potential health hazards associated with toxic materials.

- Brand protection. Helps manufacturers avoid the financial and reputational damage associated with product recalls and non-compliance penalties.

- Market confidence. Reinforces consumer trust in brands by consistently delivering safe and compliant products.

Other Types of PMI Equipment

PMI guns, which use X-ray Fluorescence (XRF) technology, are among the most common and portable types of PMI equipment. But they are not the only type of PMI equipment that inspectors use. Here are three other common types of PMI equipment:

1. Optical Emission Spectrometry (OES)

OES involves sparking the material’s surface and analyzing the emitted light’s spectrum. OES equipment is highly accurate and can detect a wider range of elements, including light elements like carbon, which are difficult for XRF to detect.

2. Laser-Induced Breakdown Spectroscopy (LIBS)

LIBS is a newer technology, in which a high-intensity laser pulse is focused on the material surface, creating a plasma. The light emitted from this plasma is then analyzed to determine the material’s composition. Like PMI guns, LIBS equipment is portable and offers rapid analysis to support work in the field.

The Thermo Fisher Niton Apollo LIBS Analyzer

Rent or buy LIBS PMI equipment:

3. Ultrasonic Testing (UT) Equipment

While not directly analyzing material composition, UT equipment is used in PMI to assess material integrity and detect internal flaws, contributing to the overall inspection and verification process. Each type of PMI equipment has its specific applications, advantages, and limitations, and the choice between them depends on the specific requirements of the inspection task, including the type of materials, the level of detail required, and the inspection environment.