Guide

Eddy Current Testing: An In-Depth Guide [New for 2025]

Eddy Current Testing (ECT) is an NDT method that employs electromagnetic induction to detect flaws, measure material thickness, and assess the properties of conductive materials.

ECT is particularly valuable to inspectors for its ability to inspect non-ferromagnetic metals such as aluminum, copper, and stainless steel without causing any damage to the material being tested.

Alternate phrases for eddy current testing include:

- Eddy current inspection (ECI)

- Electromagnetic testing (EMT)

- Eddy current evaluation (ECE)

- Eddy current examination (ECE)

- Electromagnetic induction testing (EMIT)

Eddy current testing is a useful method for identifying and evaluating flaws during inspections, including:

- Surface and near-surface cracks

- Corrosion detection

- Material thickness measurement

- Conductivity testing

Top industries for using ECT include power generation, manufacturing, and aerospace (we cover top applications for eddy current testing below).

In this in-depth overview of eddy current testing, we’ll look at the fundamentals of ECT, explore the tools and techniques used for ECT and the scenarios where ECT is most beneficial. We’ll also cover the main industries that use eddy current evaluation in their maintenance processes.

Have a specific topic in mind? Use the menu to the right to jump around within this guide.

What Is Eddy Current Testing?

Eddy Current Testing (ECT) involves generating eddy currents within a material and observing the interaction between these currents and any present flaws or discontinuities.

Principles of Eddy Current Testing

The fundamental principle of eddy current testing is based on Faraday’s Law of Electromagnetic Induction.

When an alternating current passes through a coil, it generates a changing magnetic field, which induces eddy currents in a nearby conductive material.

These currents flow in closed loops within the material and create their own magnetic fields, which interact with the original field from the coil. And identifying changes in the magnetic field can help inspectors find anomalies, identifying the presence of defects or flaws in an asset.

Here are the key steps involved in eddy current testing:

1. Generation of Eddy Currents

An alternating current is passed through a coil placed near the surface of the conductive material. This current generates a changing magnetic field that induces eddy currents in the material you’re inspecting.

2. Interaction with Material Defects

The presence of flaws, such as cracks, voids, or inclusions, disrupts the flow of eddy currents, causing changes in the magnetic field. These changes can be detected and analyzed to determine the location and size of the defects.

3. Measurement of Impedance Changes

The interaction between the eddy currents and the flaws affects the impedance of the coil. By measuring these impedance changes, inspectors can identify and characterize defects within the material.

Advantages of Eddy Current Testing

- Non-destructive. ECT does not damage the material being inspected, allowing for repeated testing and continued use of the component.

- Surface and subsurface inspection. Can detect both surface and subsurface defects, providing a comprehensive evaluation of the material’s integrity.

- High sensitivity. The technique is highly sensitive to small defects, making it ideal for detecting minute cracks and other imperfections.

- Versatility. Can be used on a wide range of conductive materials, including non-ferromagnetic metals and alloys.

- Immediate results. Provides real-time results, enabling quick decision-making and reducing inspection times.

Limitations of Eddy Current Testing

- Limited depth penetration. ECT is primarily effective for detecting flaws near the surface of a material. Its effectiveness decreases with increasing depth.

- Conductivity requirements. The material being inspected must be electrically conductive, limiting the applicability of ECT to certain types of materials.

- Complex interpretation. The interpretation of eddy current signals requires skilled operators with extensive training and experience.

Eddy Current Testing Tools

Eddy Current Testing (ECT) employs a variety of specialized tools and equipment designed to generate, control, and detect eddy currents within conductive materials. These tools are essential for performing accurate and reliable electromagnetic testing.

Below are the primary tools used in eddy current testing. We’ve organized these tools into four categories, with specific types listed for each one (some categories only have one type).

1. Eddy Current Probes

I. Surface probes are probes designed for inspecting surface and near-surface flaws in conductive materials.

- How they work. Surface probes generate eddy currents that flow parallel to the surface of the material, detecting surface-breaking cracks and other discontinuities.

- Applications. Used for inspecting aircraft fuselage skins, heat exchanger tubes, and other surface components.

II. Encircling (bobbin) probes are probes that encircle the test material, commonly used for tubular structures.

- How they work. Encircling probes induce eddy currents circumferentially around the material, detecting defects on both the inside and outside surfaces.

- Applications. Ideal for inspecting pipes, tubes, and cylindrical components.

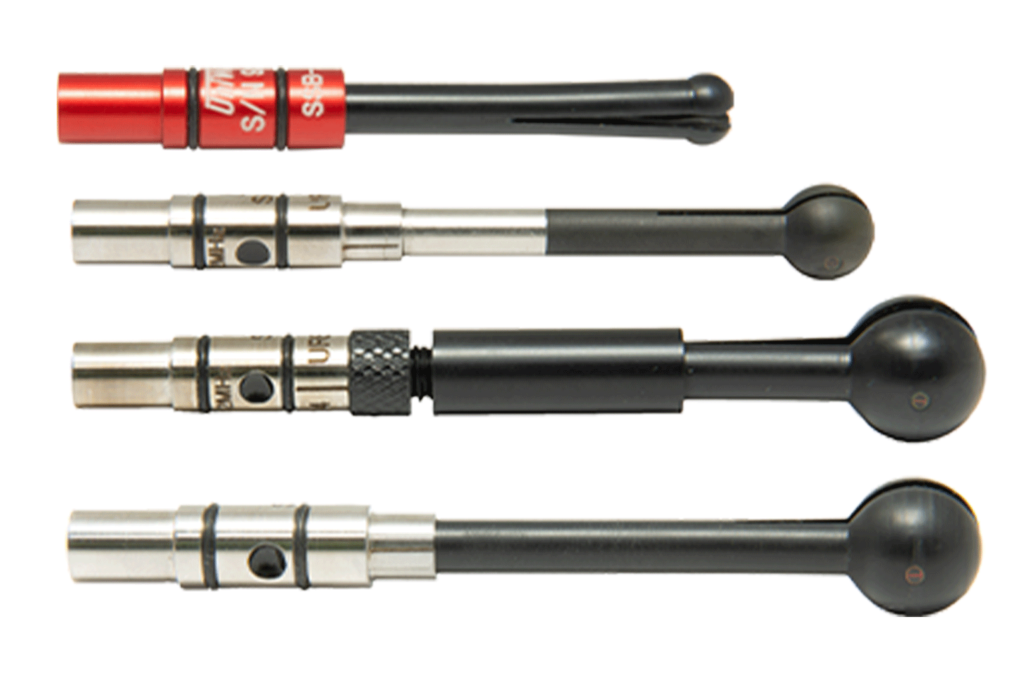

III. Pencil probes are small, handheld probes with a narrow tip for high-resolution inspections.

- How they work. Pencil probes provide precise eddy current generation and detection, making them suitable for detecting small cracks and localized defects.

- Applications. Used for detailed inspections in aerospace and precision manufacturing industries.

2. Eddy Current Instruments

I. Portable eddy current flaw detectors are handheld or portable devices used to generate and measure eddy currents in the test material.

- How they work. These instruments produce alternating currents to generate eddy currents and measure the resulting impedance changes to detect defects.

- Applications. Widely used in field inspections and maintenance operations due to their versatility and ease of use.

II. Multi-frequency eddy current instruments are advanced devices capable of operating at multiple frequencies to inspect a wide range of materials and defect types.

- How they work. Multi-frequency instruments can adjust the frequency of the alternating current to optimize eddy current penetration and sensitivity for different materials and flaw depths.

- Applications. Suitable for complex inspections requiring different frequency settings, such as those needed in aerospace and power generation industries.

3. Data Acquisition and Analysis Software

I. Eddy current analysis software is computer software designed to collect, display, and analyze eddy current data in real-time.

- How they work. The software processes signals from the eddy current instruments, providing visual representations of impedance changes and identifying defect locations and sizes.

- Applications. Used to enhance the accuracy and efficiency of eddy current inspections, allowing for detailed reporting and data storage.

II. Impedance plane analysis tools are specialized tools for visualizing and interpreting impedance changes on an impedance plane.

- How they work. These tools display the complex impedance data as points or loops on an impedance plane, helping inspectors distinguish between different types of defects and material properties.

- Applications. Essential for advanced defect characterization and material property analysis.

4. Calibration Standards and Reference Blocks

I. Calibration standards are known samples with predetermined flaws and material properties used to calibrate eddy current instruments.

- How they work. Calibration standards help ensure the accuracy and reliability of eddy current measurements by providing reference signals for comparison.

- Applications. Used regularly to calibrate equipment before inspections, ensuring consistent and accurate defect detection.

II. Reference blocks are blocks of material with artificial defects or known properties used for training and calibration.

- How they work. Reference blocks simulate real-world inspection scenarios, helping technicians understand how different defects appear in eddy current signals.

- Applications. Used for training purposes and validating inspection techniques.

Types of Eddy Current Testing

Electromagnetic testing utilizes a variety of techniques, each designed for specific inspection requirements and applications.

These techniques differ in their methods and the types of eddy current interactions they employ, and different industries require different types of ECT based on their unique materials and needs.

Here are the main types of eddy current testing:

1. Surface Eddy Current Testing

The most common type of eddy current testing, focused on detecting surface and near-surface defects.

- How it works. Surface probes induce eddy currents that flow parallel to the surface of the material. Discontinuities such as cracks disrupt these currents, causing changes in impedance that are detected by the probe.

- Applications. Widely used for inspecting aircraft skins, heat exchanger tubes, and other components where surface integrity is critical.

2. Encircling (Bobbin) Coil Testing

A method specifically designed for inspecting cylindrical objects,like pipes and tubes.

- How it works. Encircling coils generate eddy currents circumferentially around the object. Defects on the inner or outer surfaces cause changes in the eddy current flow, which are detected by the coil.

- Applications. Commonly used in the oil and gas industry for pipeline inspection, and in power generation for steam generator tubing.

3. Pencil Probe Testing

A high-resolution eddy current testing method using small, focused probes.

- How it works. Pencil probes create localized eddy currents, allowing for detailed inspection of small areas and the detection of minute cracks.

- Applications. Ideal for precision inspections in the aerospace and manufacturing industries, in which small cracks or defects can have significant implications for safety or for the integrity of a finished product.

4. Array Eddy Current Testing

An advanced technique that uses multiple coils arranged in an array to cover larger areas quickly.

- How it works. Array probes generate and detect eddy currents simultaneously at multiple points, providing comprehensive coverage and faster inspection times.

- Applications. Large-scale inspections, such as aircraft fuselages, ship hulls, and large industrial components.

5. Pulsed Eddy Current Testing

A technique that uses pulsed rather than continuous alternating currents to generate eddy currents.

- How it works. Pulsed eddy currents provide better depth penetration and are less affected by material lift-off, making them useful for doing inspections through layers like coatings or insulation.

- Applications. Used in the oil and gas industry for inspecting pipelines with protective coatings and in power generation for inspecting insulated components.

When Is Eddy Current Testing Required?

Eddy Current Testing (ECT) is essential in various scenarios to ensure the quality, safety, and reliability of conductive materials and components.

Here are key situations that call for eddy current testing:

1. Quality Control and Assurance

- Manufacturing processes. During production, ECT is used to verify that materials and components meet specified quality standards. Doing this involves detecting internal and surface defects such as cracks, voids, and inclusions to ensure the integrity of the final product.

- Incoming material inspections. Electromagnetic testing is employed to inspect raw materials before they are used in manufacturing. This ensures that only defect-free materials are used, reducing the risk of failures in finished products.

2. Weld Inspection

- Weld integrity. Eddy current testing is crucial for inspecting welds to detect internal and surface flaws such as cracks, lack of fusion, and porosity. Ensuring weld integrity is critical for the structural safety of the welded joints.

- Post-weld heat treatment (PWHT). After heat treatment, inspectors examine welds using ECT to ensure no new defects have formed and that the welds maintain their integrity.

3. Corrosion Detection

- Corrosion monitoring. ECT is widely used to detect and monitor corrosion in conductive materials. This includes identifying areas of corrosion under insulation or coatings, which can be challenging to inspect using other methods.

- Thickness measurement. ECT can measure the thickness of metal components, helping to identify thinning due to corrosion and ensuring that parts are replaced before they fail.

4. Preventive Maintenance

- Scheduled inspections. Eddy current testing is part of routine maintenance schedules to monitor the condition of critical components and infrastructure. Doing this helps in the early detection of potential issues, preventing unexpected failures and downtime.

- Condition monitoring. Continuous or periodic ECT inspections enable the monitoring of components under operational conditions, providing valuable data on their health and predicting their remaining service life.

5. Safety Compliance

- Regulatory requirements. Many industries are subject to stringent safety regulations that mandate regular eddy current testing. Compliance with these regulations ensures that components and structures meet safety standards, reducing the risk of accidents.

- Certification and accreditation. ECT is often required for certification purposes, such as obtaining pressure vessel and pipeline certifications from regulatory bodies.

6. Research and Development

- Material characterization. In research and development, ECT helps characterize new materials, studying their properties and behavior under different conditions. This information is vital for developing advanced materials with enhanced performance.

- Prototype testing. ECT is used to evaluate prototypes, identifying any flaws or weaknesses that need to be addressed before full-scale production.

The Top 5 Industries that Rely on Eddy Current Testing + Specific Applications They Use

Eddy Current Testing (ECT) finds applications across a wide range of industries, helping inspectors obtain critical insights into the integrity of conductive materials and components.

Here are the top five industries that use electromagnetic testing, with specific applications covered for each one.

1. Oil and Gas

In the oil and gas industry, eddy current testing is vital for maintaining the safety and reliability of pipelines and other infrastructure.

- Pipeline inspections. ECT is used to detect corrosion, cracks, and other defects in pipelines, ensuring their integrity and preventing leaks or ruptures that could lead to environmental disasters.

- Drill pipe and casing inspections. Inspecting drill pipes and casings for defects that could compromise the safety and efficiency of drilling operations.

- Heat exchanger and boiler tube inspections. Inspecting heat exchanger and boiler tubes for defects, ensuring their efficient operation and preventing unexpected failures.

2. Power Generation

In the power generation industry, eddy current testing is crucial for maintaining the integrity of critical components in power plants.

- Steam generator tube inspections. ECT is used to inspect steam generator tubes in nuclear and fossil-fuel power plants for corrosion, wear, and other defects. Doing this ensures the safe and efficient operation of the power plant.

- Turbine blade inspections. Detecting cracks and other defects in turbine blades, which can lead to catastrophic failures if not identified and addressed promptly.

- Condenser tube inspections. Monitoring the condition of condenser tubes, detecting issues such as fouling, corrosion, and tube thinning.

3. Manufacturing

In the manufacturing industry, eddy current testing is essential for ensuring product quality and reliability.

- Quality assurance. ECT is used to inspect raw materials, intermediate products, and final assemblies for internal and surface defects such as cracks, voids, and inclusions. Doing this ensures that only defect-free products reach the customer.

- Machined part inspections. Inspecting machined parts for defects, ensuring they meet design specifications and tolerances.

- Surface coating inspections. Inspecting surface coatings for thickness and uniformity, ensuring they provide adequate protection and meet quality standards.

4. Automotive

The automotive industry employs eddy current testing to ensure the quality and safety of vehicle components.

- Engine component inspections. ECT is used to inspect critical engine components like cylinder heads, crankshafts, and camshafts for surface and subsurface defects, ensuring they meet safety and performance standards.

- Wheel and axle inspections. Detecting cracks and other defects in wheels and axles, ensuring they can withstand operational stresses and maintain vehicle safety.

- Weld inspections. Inspect welds in vehicle frames and body panels, ensuring they are free from defects and can withstand operational stresses.

5. Aerospace

The aerospace industry relies heavily on eddy current testing to maintain the safety and performance of aircraft components.

- Aircraft structural inspections. ECT is used to inspect critical structural components, including wings, fuselage sections, and engine parts, for surface and subsurface defects. Ensuring these components are free of flaws is vital for flight safety.

- Heat exchanger tube inspections. Inspecting heat exchanger tubes for corrosion, erosion, and other defects, ensuring the efficient operation of cooling systems in aircraft.

- Landing gear inspections. Detecting cracks and other defects in landing gear components, which are subjected to high stresses during takeoff and landing.

Best Practices for Eddy Current Testing

To ensure the effectiveness and reliability of eddy current testing (ECT) it’s important to follow established guidelines.

These best practices will help maximize the accuracy of your inspections and minimize the risks associated with the testing process.

1. Proper Training and Certification

- Qualified personnel. Ensure that eddy current testing is conducted by trained and certified technicians. Certification from recognized bodies such as the American Society for Nondestructive Testing (ASNT) or equivalent organizations is essential.

- Continuous education. Encourage ongoing education and training to keep technicians updated on the latest techniques, equipment, and industry standards. This can include workshops, seminars, and certification renewal courses.

2. Appropriate Equipment Selection

- Probe selection. Choose the right type of probe based on the material and type of inspection. Factors to consider include the shape, size, and frequency of the probe.

- Instrumentation. Use appropriate eddy current instruments that match the inspection requirements. Advanced instruments with multi-frequency capabilities and digital interfaces can provide more detailed and accurate results.

- Calibration standards. Employ calibration standards and reference blocks that match the material and defect types expected in the inspection. Regularly calibrate the equipment to maintain accuracy.

3. Surface Preparation

- Clean surfaces. Ensure that the surfaces to be inspected are clean and free from contaminants such as dirt, grease, and paint. Contaminants can impede the generation and detection of eddy currents.

- Smooth surfaces. Smooth out rough or uneven surfaces as much as possible to improve contact between the probe and the material.

4. Inspection Procedures

- Standard operating procedures (SOPs). Develop and adhere to detailed SOPs for each type of eddy current inspection you do. SOPs ensure consistency, thoroughness, and compliance with regulatory requirements.

- Proper positioning. Position the probe accurately to obtain clear and detailed signals from the area of interest. Use fixtures or guides if necessary to maintain consistent positioning.

- Signal interpretation. Technicians should be skilled in interpreting eddy current signals to accurately identify and characterize defects. Understanding the nuances of signal phase, amplitude, and frequency response is essential.

5. Data Acquisition and Analysis

- Real-time monitoring. Use eddy current instruments that provide real-time monitoring and display of signals, allowing for immediate detection and analysis of defects.

- Data recording. Record and store inspection data systematically. This helps in tracking the condition of components over time and provides valuable information for future inspections.

- Advanced software. Use advanced data analysis software that can enhance signal interpretation, generate detailed reports, and store inspection records efficiently.

6. Regular Equipment Maintenance

- Routine checks. Perform regular maintenance and routine checks on your eddy current testing equipment to ensure it’s in good working condition. This includes inspecting cables, connectors, and probes for wear and damage.

- Calibration. Regularly calibrate equipment according to manufacturer guidelines and industry standards to maintain accuracy and reliability.

- Software updates. Keep software for eddy current systems and data analysis up-to-date to take advantage of the latest features and improvements.

7. Safety Protocols

- Protective gear. Ensure that technicians wear appropriate protective gear, such as gloves and safety glasses, to protect against hazards associated with the testing environment.

- Safe practices. Follow safe practices to prevent accidents, especially when dealing with large or heavy components, high-voltage equipment, or elevated work areas.

8. Compliance with Regulations

- Regulatory standards. Ensure compliance with all relevant regulatory standards and guidelines for eddy current testing. This includes obtaining necessary certifications and adhering to industry best practices.

- Inspections and audits. Conduct regular inspections and audits to verify compliance with safety protocols and regulatory requirements. Address any identified issues promptly to maintain a safe and compliant inspection environment.