Resources / Case Study / MFE Supports Acuren in Drone-Based Workflow for Comprehensive Stack Inspections

Case Study

MFE Supports Acuren in Drone-Based Workflow for Comprehensive Stack Inspections

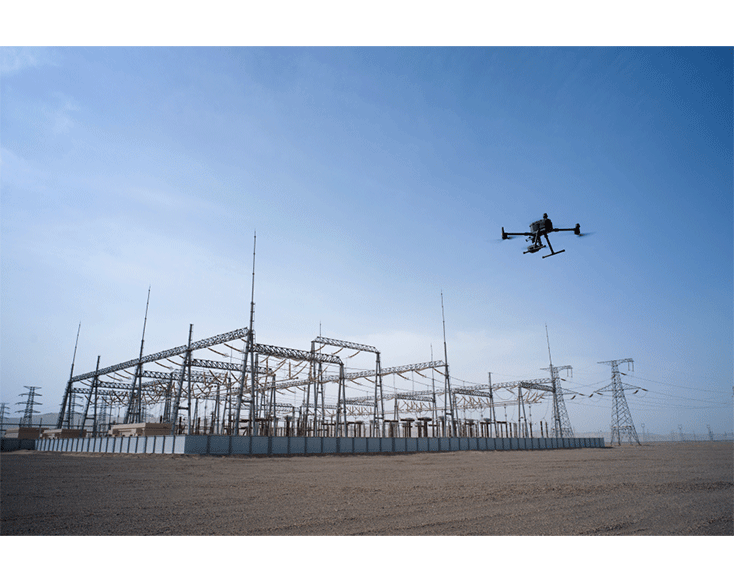

When a refinery needed a safer, faster way to inspect dozens of stacks, it turned to Acuren. Working with MFE Inspection Solutions, Acuren created a new workflow that uses three inspection drones—the DJI Matrice 350, the Voliro T, and the Elios 3—to get comprehensive coverage of the stack with minimal downtime.

Benefits

Minimal Downtime

Inspections were largely performed while stacks remained active, avoiding costly shutdowns and disruptions to nearby operations.

Complete Coverage of Stack Integrity

Acuren’s new stack inspection workflow uses three drone platforms to capture data inside and outside the stack—including thermal data, UT data, and visual data—delivering a full picture of each stack’s integrity.

Lower Costs, Better Planning

The workflow allowed clients to identify issues early, fabricate parts in advance, and reduce the length and cost of planned turnarounds.

Introduction

For refineries, stack integrity is essential.

Yet inspections are often skipped because traditional methods using scaffolding, cranes, or rope access are too costly, disruptive, and dangerous to perform regularly.

Acuren, working with MFE Inspection Solutions, has developed a new workflow that removes these barriers. By integrating drone-based thermal imaging, external UT with the Voliro T, and internal inspections with the Elios 3, the process delivers complete coverage of stack health with minimal operational impact.

The result is safer teams, earlier detection of problems, and shorter, more efficient turnarounds that save refineries millions in avoided downtime.

The Challenge

Stacks are vital to refinery operations, but inspecting them with traditional methods has always been a challenge.

Scaffolding, cranes, man lifts, and rope access all come with steep costs, dangerous working conditions, and major delays. Building and taking down scaffolding can take days and cost millions, while rope access requires technicians to rappel hundreds of feet inside confined, hazardous spaces.

And the disruption extends beyond the inspection itself. Bringing in cranes or scaffolding can block other work, force shutdowns for neighboring assets, and add weeks to a turnaround schedule. These barriers often mean inspections are postponed—or skipped entirely.

The risks of neglect are severe. In multiple cases, stacks have collapsed due to unchecked wall thinning, with failures traced back to missed inspections and refractory loss. Every extra hour of unplanned downtime adds millions to a refinery’s bottom line.

Faced with these costs, risks, and limitations, operators needed a new way to inspect stacks—one that could deliver complete coverage without the dangers and delays of traditional methods.

“Most facilities don’t even know these tools exist. When I tell them we can do UT by drone, they don’t believe me at first. But then we show them hundreds of stacks we’ve already inspected, and the results speak for themselves.”

Omar Hasan, Regional Drone Operations Manager at Acuren

The Solution

With support from MFE, Acuren has developed a new drone-based approach to stack inspections that delivers complete coverage of stack integrity.

Instead of relying on a single tool or method, the process integrates multiple drone-based technologies into one coordinated workflow.

The process requires three distinct steps:

1. Initial Thermal Screening

- Drone: DJI Matrice 350 RTK or Mavic 3 Enterprise Thermal

- Downtime: None, stack remains online

Rapid, non-contact scans identify hot spots that may indicate refractory loss, creating a heat map of risk so teams don’t inspect every surface equally. This first pass prioritizes where to take drone-based ultrasonic thickness readings in the next step.

2. External UT Data Collection

- Drone: Voliro T equipped with its high-temp UT probe

- Downtime: None, stack remains online

Guided by the thermal map, Acuren inspectors use the Voliro T to collect targeted wall-thickness (UT) data across the stack while it remains in operation, concentrating on flagged areas. UT data at this stage confirms thinning early, avoids unnecessary shutdowns, and gives operators time to pre-fabricate parts.

3. Internal Visual Data Collection

- Drone: Flyability Elios 3

- Downtime: Required, but done during a planned turnaround for maximum efficiency

Once the unit is offline, the Elios 3 provides visual confirmation of refractory loss, documents its extent and elevation, and validates the cause of earlier hot spots or thinning—tightening the repair scope and informing scaffold/repair plans. The platform can also be equipped with a UT probe to collect internal thickness data if needed.

A New Approach for Comprehensive Stack Inspections

What sets this approach apart is how the steps build on one another.

Thermal data identifies potentially thin areas, which are then validated by UT data collected on the outside of the stack. Then, during a planned turnaround, internal inspection validates these findings, giving refineries a complete picture of stack health with minimal disruption to operations.

With MFE’s partnership, Acuren has transformed this process into a repeatable approach that is safer, faster, and more reliable than traditional methods.

“MFE’s equipment and technical support have made all the difference in helping us turn these tools into a repeatable workflow. The barrier to entry is high, but with their help the reward is high too.”

Omar Hasan, Regional Drone Operations Manager at Acuren

The Results

Acuren’s comprehensive workflow has transformed how refineries approach stack inspections.

An inspection that once required scaffolding, cranes, or rope access can now be completed faster, safer, and with minimal disruption to operations—and scaled across dozens of stacks in just weeks instead of months.

By combining thermal imaging, external UT with the Voliro T, and internal inspections with the Elios 3, refineries get early insight into potential issues, can pre-fabricate parts, and shorten shutdown schedules.

The approach has already helped operators reinforce structures, patch thinning plates, and prevent failures that would otherwise lead to costly downtimes.

Key results include:

- Faster inspections. Dozens of stacks completed in weeks instead of months.

- Zero downtime for external UT. Wall-thickness data collected while stacks remain online.

- Earlier detection of issues. Thermal scans guide UT targeting for proactive planning and fabrication.

- Safer teams. No scaffolding, cranes, or rope access required.

- Reduced turnaround time. Internal inspections validate findings and help shorten shutdowns.

- Proven value. Facilities benefit from more reliable data and reduced backlogs, saving millions in avoided downtime.

In an industry where every hour of downtime carries a multimillion-dollar cost, the value of faster, more thorough inspections is clear: Acuren’s process, enabled by MFE, is setting a new standard for stack integrity management.

Conclusion

Acuren’s complete-coverage workflow shows that innovation in refinery inspections often comes not just from new inspection tools, but from smarter ways of using them.

With MFE’s expertise, Acuren has turned advanced drone technologies into a practical, repeatable process that improves safety, reduces downtime, and delivers more reliable data.

As Acuren’s new workflow is adopted more broadly, it offers refineries a clear blueprint for the future of stack integrity management—one built on efficiency, foresight, and smarter planning.

Share