Tough Jobs Demand Tougher NDT Equipment

Stay Industry Compliant with

Reliable NDT Solutions

Why Choose MFE’s NDT Equipment?

Accurate

Ensure compliance with industry standards with high-precision NDT tools.

Dependable

Our equipment is engineered for reliability, delivering consistent, accurate results even in harsh Canadian environments.

Safe

Reduce risk with remote visual inspection & robotics, minimizing the need for confined space entry and disassembly.

MFE’s NDT Equipment

Struggling to meet industry compliance? Need inspection tools ASAP?

At MFE Inspection Solutions, we provide advanced NDT equipment—available for immediate rental or purchase—to help you stay compliant, prevent costly shutdowns, and maintain operational efficiency.

Don’t risk compliance penalties or delays. Get the right tools—when you need them.

NDT Products We Offer

- Acoustic Imaging

- XRF Elemental Analyzers

- Gas Detection Cameras

- Ground Penetrating Radar

- Hardness Testers

- Holiday Testers

- Infrared Cameras

- Material Testing Equipment

- MFL Scanners

- Ultrasonic Thickness Gauges

- Push Camera Systems

- Borescopes/Videoscopes

- Tank Inspection Systems

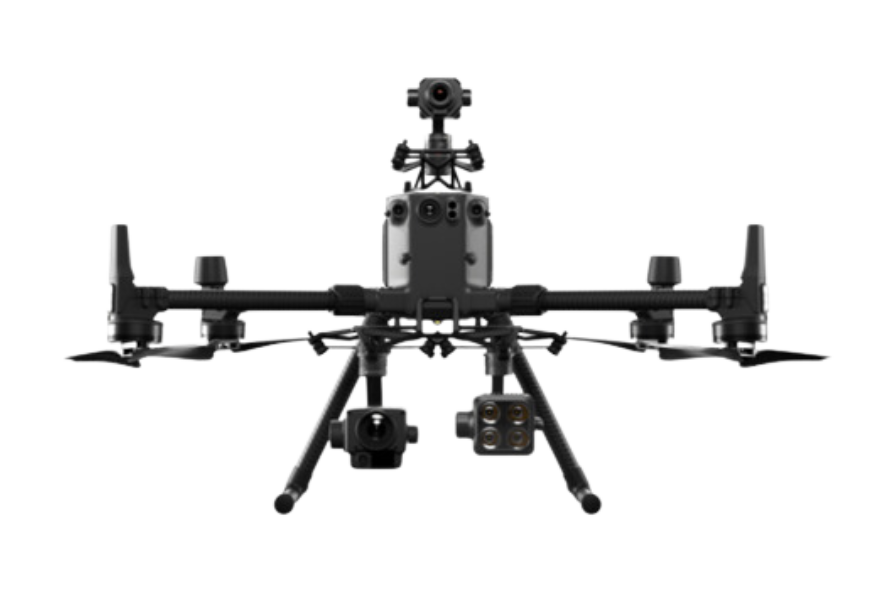

- Advanced Robotics

Need Equipment Fast? Request a Quote Today.

Equipment Catalogs

Find the right NDT equipment fast—whether you need rentals for urgent inspections or advanced tools for long-term compliance. Browse our catalogs below to explore inspection-ready solutions that help you stay compliant, reduce downtime, and ensure inspection accuracy. Request a quote today and get the right tools—when you need them.

Featured Equipment

Olympus 38DL Plus

Ultrasonic Thickness Gauge

USES

This advanced ultrasonic gauge provides high-accuracy, non-destructive thickness measurements for metals, plastics, and composites, ensuring regulatory compliance and proactive maintenance.

ASSETS

Ideal for pipelines, storage tanks, pressure vessels, and structural components, the 38DL Plus ensures early detection of material thinning and corrosion, reducing costly repairs and failures.

INDUSTRIES

Used in oil & gas, manufacturing, power generation, and aerospace, the Olympus 38DL Plus supports industries adhering to industry standards for structural integrity and safety.

Mark IV

Tank Floor Scanner

USES

Designed for fast, non-destructive detection of corrosion and pitting, the Mark IV delivers detailed floor condition assessments, helping facilities schedule targeted repairs and maintain regulatory compliance.

ASSETS

Used for aboveground storage tanks in oil & gas, petrochemical, and bulk storage industries, the Mark IV ensures comprehensive corrosion mapping and supports safety protocol standards.

INDUSTRIES

Essential for facilities operating under stringent standards for fuel storage, handling, and safety compliance, ensuring longer service life and reduced environmental risk.

Eddify Ectane 2

Eddy Current Flaw

Detector

USES

This multi-technology NDT system enables crack detection, corrosion monitoring, and thickness measurement in conductive materials, supporting inspection protocols.

ASSETS

Optimized for pipelines, tanks, welds, heat-affected zones, and tubing, the Ectane 2 provides precise flaw detection and material condition assessment.

INDUSTRIES

Used in oil & gas, nuclear power, aerospace, and manufacturing, the Ectane 2 aligns with industry standards for infrastructure safety, material integrity, and quality control.

Why Industry-Compliant NDT Matters

AVOID COMPLIANCE PENALTIES

Standardizing bodies require regular inspections for pipelines, tanks, and pressure vessels. Non-compliance can result in fines, shutdowns, and liability risks.

PREVENT UNPLANNED OUTAGES

Equipment failure costs millions in lost production. Early detection saves money.

ENSURE STRUCTURAL INTEGRITY

NDT protects your pipelines, pressure vessels, and storage tanks, ensuring long-term performance & safety.

SAVE ON COSTLY REPAIRS

Catching defects early prevents catastrophic failures and unplanned shutdowns.

How to Choose the Right Inspection Equipment for your next Industry Compliant Inspection

MATERIAL TYPE & SHAPE

Different materials require specialized NDT methods for accurate inspections.

OBJECT SIZE & ACCESSIBILITY

Large assets need drone or remote visual inspections for full coverage.

DEFECT TYPE & LOCATIONS

Surface vs. subsurface defects require different NDT techniques.

COST & TIME EFFICIENCY

Faster, automated solutions reduce inspection costs & downtime.

NDT FAQs

Explore answers to common questions about Non-Destructive Testing (NDT), including its reliability, the equipment used, the five most common methods, and its ability to detect various defects.

Yes, NDT is highly reliable, providing accurate, non-invasive evaluations of materials and structures, which helps in identifying defects without causing damage.

NDT uses various equipment such as ultrasonic thickness gauges, borescopes, magnetic particle testers, eddy current detectors, radiographic imaging devices, and drones and robotics.

The five most common NDT methods are ultrasonic testing (UT), magnetic particle testing (MPT), eddy current testing (ECT), radiographic testing (RT), and visual inspection (VI).

NDT can detect many types of defects, including cracks, corrosion, voids, and inclusions. However, its effectiveness depends on the method used and the specific defect type.

Testimonials

The staff have always been helpful, but during my last rental with them, John noticed an issue with my vehicle and then gave us shop supplies to complete an emergency fix. This is just the latest time John and Scott have gone above and beyond what would be expected from a rental company. I highly recommend MFE for your NDE rentals.

Gary Belter

Edmonton, AB

I have known the staff at MFE for many years. Aaron and his team go out of their way to ensure that the rental experience is great. They provide great equipment (well maintained, calibrated, reliable) with personal service and reliable delivery. I would recommend MFE for your rental needs.

Rob Robinson

Toronto, ON