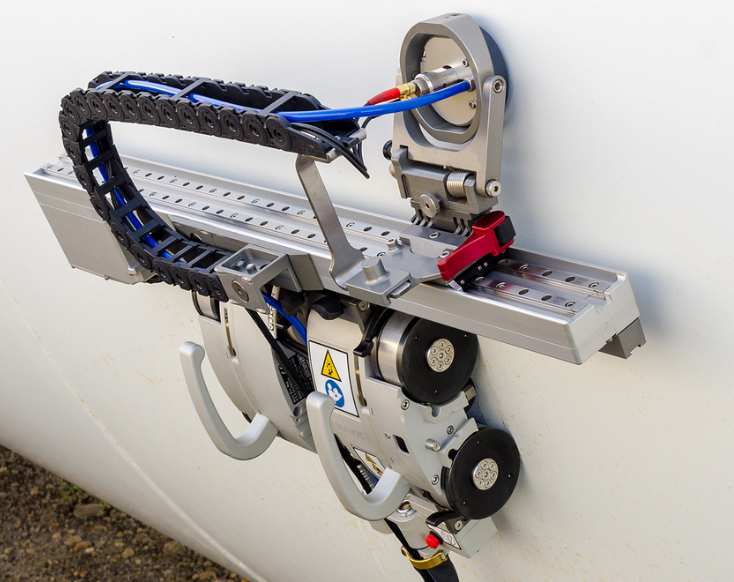

The NAVIC 2 Corrosion Mapping Scanner combines the NAVIC 2 motorized crawler with the motorized raster arm to form a fully automated, two-axis inspection solution for ferrous assets. Think of it as a robotic assistant built for precision—capable of scanning large vertical surfaces like storage tanks and pressure vessels with consistent accuracy, while reducing the need for scaffolding, manual scanning, or guesswork.

The NAVIC 2 adheres magnetically to steel surfaces and moves with remote-controlled precision while the motorized raster arm handles the fine movements—systematically guiding the probe across the scan area like a printer laying down ink—ensuring full coverage and repeatable results. Ideal for oil & gas, petrochemical, and power generation sectors, this system helps teams detect corrosion early, capture higher-quality data, and complete inspections faster, safer, and with greater confidence.

Equipment Type: Ultrasonic Thickness Scanner

Demande de devis

The NAVIC 2 with the motorized raster arm is a durable, field-proven scanning platform purpose-built for automated corrosion mapping on ferrous surfaces. Designed for heavy industrial environments, it combines rugged construction with precise motion control to deliver consistent, high-quality data in demanding inspection scenarios.

With remote operation, programmable scan paths, and minimal setup complexity, this system helps reduce manual scanning variability while increasing operator efficiency and safety.

With powerful magnetic wheels delivering secure adhesion to ferrous surfaces, the NAVIC 2 maintains reliable contact during scanning—whether moving vertically, horizontally, or circumferentially.

Its motorized drive and steerable design allow smooth, responsive control via handheld remote, with variable speeds up to 25 cm/sec (10 in/sec).

The system’s strong magnetic base supports payloads up to 10 kg (22 lb) on vertical surfaces, while enabling accurate, repeatable motion across storage tanks and pressure vessels.

This rock-solid grip and agile movement are critical for collecting high-resolution data with consistency and confidence.

The motorized raster arm turns the NAVIC 2 into a smart, two-axis scanning system that works like a robotic painter—systematically covering every inch of the inspection area with precision and consistency.

Operators can program the scan pattern in advance, setting how far the probe moves, how fast it travels, and how much it shifts between each pass.

With stroke lengths up to 1160 mm (45.7 in) and scan speeds reaching 762 mm/sec (30 in/sec), the system produces clean, repeatable C-scans and corrosion maps, reducing human error and speeding up inspections without compromising data quality.

The NAVIC 2 system delivers precise scan results without the complexity. High-resolution encoders—essentially the digital “measuring tapes” built into both the crawler and the raster arm, track every movement down to fractions of a millimeter.

With resolutions up to 872.5 counts/mm, the system knows exactly where the probe is at all times, producing crisp, detailed corrosion maps with minimal manual adjustment.

Combined with quick-connect components and intuitive setup, this means you get consistent, high-quality data, faster and with less hassle in the field.

With the NAVIC’s handheld remote, you don’t need to be right next to the action. The system can be controlled from up to 30 meters (100 feet) away, letting you guide scans with pinpoint accuracy while staying safe and out of the way.

The integrated umbilical cable delivers power, data, and control signals over long distances, keeping everything running smoothly even in tough, large-scale environments.

From long shifts in remote environments to large-scale tank inspections, the NAVIC 2 system is built to perform when reliability matters most. It runs on standard AC power (100–240 VAC) or with an optional battery kit, giving you the flexibility to work in the field without interruption.

With a dust-tight, watertight design and full compliance with CE, FCC, and UKCA standards, it’s built to handle tough industrial conditions while delivering consistent, high-quality results.

Rent the NAVIC 2 with Motorized Raster Arm and get the job done faster, safer, and with precision you can trust.

| Idler Encoder (Right Module) | 13.78 counts/mm (349.9 counts/inch) |

| Motor Encoder (Left Module) | 872.5 counts/mm (22162.8 counts/inch) |

| Crawler’s Vertical Payload | 10 kg (22 lb) |

| Driving Speed | Variable 0 – 25 cm/sec (0 – 10 in/sec) |

| Exigences en matière d'alimentation | 100-240VAC, 50/60Hz, 3.5 Amps |

| Umbilical Lengths | 30 m (100 ft) |

| Inspection Surface | Ferrous |

| Maximum Backpack Payload | 1.36 kg (3 lb) |

| Pipe Range, Circumferential | 7 cm (2.75 in) to flat pipe |

| Range, Internal Circumferential | 61 cm (24 in) to flat |

| Pipe Range, Longitudinal | 30.5 cm (12 in) to flat |

| Raster Arm Module Encoder | 240.2 counts/mm (6100.9 counts/inch) |

| Raster Arm Module Speed | 0 - 76.2 cm/sec |

| Base Crawler Height (including handles) | 12.5 cm (4.9 in) |

| Base Crawler Height (handles removed) | 8.1 cm (3.2 in) |

| Base Crawler Width (Dual Pod) | 28.2 cm (11.1 in) |

| Base Crawler Length | 30.8 cm (12.1 in) |

| Base Crawler Width (Single Pod) | 16.1 cm (6.3 in) |

| Base Crawler Weight | 7.7 kg (17 lb) |