The GSSI Flex NX is an advanced concrete scanning system that uses ground penetrating radar (GPR) to reveal what’s hidden within and beneath concrete surfaces, helping professionals safely and accurately locate rebar, post-tension cables, conduits, and other metallic and non-metallic objects before cutting, coring, or drilling.

Designed to be simple, flexible, and trusted, the Flex NX features a unique one-pass cross-polarization design for enhanced visibility of targets, along with an innovative Flex Positioning system that enables real-time area identification without complex setup. Engineered for the harshest jobsite environments with an IP65 rating and a wide operating temperature range, the Flex NX supports a range of industries, from construction and infrastructure maintenance to non-destructive testing and specialized GPR applications—making it the new standard in concrete scanning.

Equipment Type: Ground Penetrating Radar

Demande de devis

Understanding what’s inside concrete is critical before any work begins, but too often, scanning tools slow down workflows or deliver incomplete information. The Flex NX changes that by streamlining how subsurface data is captured and interpreted on the jobsite.

Engineered for clarity and efficiency, it helps field teams make faster, more informed decisions, without the need for complex setups or extra steps. The result is a smoother, more confident approach to locating embedded elements, planning operations, and avoiding costly mistakes.

Many scanning systems require multiple passes from different directions to catch everything buried in concrete. The Flex NX solves this with its Cross Polarization Design, which uses two antennas set at different orientations to collect data simultaneously. This allows the system to detect objects like rebar, conduit, or post-tension cables that might be invisible from a single angle, all in one efficient pass.

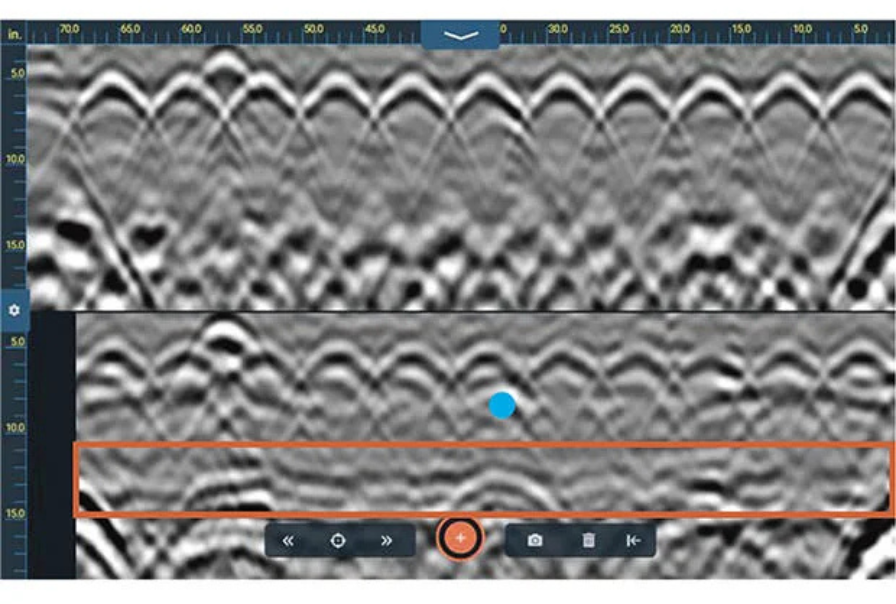

Stacked mode brings both data channels together on screen for side-by-side interpretation. You get a more complete view of the subsurface without guesswork or repeated scans. It’s like viewing a complex image from two angles at once—what’s hidden in one becomes clear in the other.

When locating something important under concrete, the last thing you want is to lose track of where it was. The Flex NX includes side lasers that project directly onto the surface, letting you mark targets as you find them with precision and speed. Each laser corresponds to its antenna’s orientation, helping you map standard and cross-polarized findings with confidence.

Target tagging on the display takes it further by letting you tap any point of interest and instantly view its depth and location. You can assign colors, review distances, and organize your findings without stepping away from the scan. It’s a faster, more reliable way to keep your data connected to the real world.

Traditional concrete scanning often depends on fixed grids or external tracking systems, which take time to set up and limit flexibility. The Flex NX removes those constraints with the Flex Positioning System, which allows you to scan naturally without predefined layouts. You can start anywhere, move in any direction, and still capture accurate spatial data as you go.

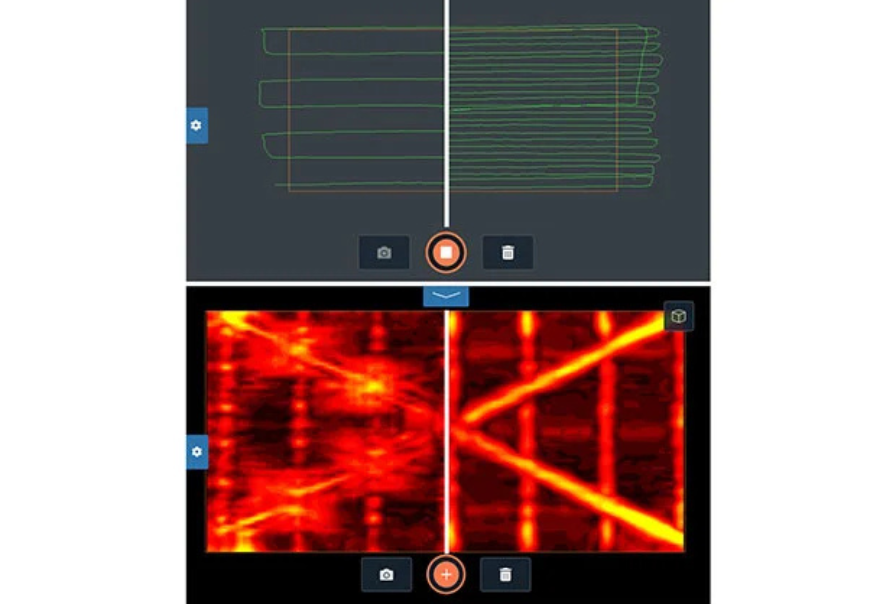

Flex Mode builds on that freedom by turning the system into a lightweight, handheld imaging tool. It gives you real-time top-down and 3D volume views of the area you’re scanning, without needing external sensors or extra equipment.

Think of it like switching from a rigid blueprint to an interactive map that updates as you move—scanning becomes more intuitive, and the data is easier to use for planning, verification, and communication.

Accurate depth measurement is one of the most important parts of scanning concrete. The Flex NX supports this with customizable dielectric settings and depth calibration options. You can adjust for how cured the concrete is—very dry, damp, or anywhere in between—or fine-tune using methods like hyperbola matching or entering a known target depth. These adjustments ensure your depth readings reflect actual jobsite conditions.

Backup cursors provide additional confidence. Because the antennas are offset, the Flex NX displays red and green cursors that align with each antenna’s targets. This makes it easy to see exactly where an object is in relation to both channels and reduces uncertainty. It’s like having two measurements confirm the same point, giving you assurance that your data is correct before moving forward.

The Flex NX is more than a concrete scanner—it’s a complete system designed for demanding jobsites. Beyond its advanced scanning capabilities, it offers multilingual support and fully customizable system settings, so it adapts to the way you work.

Project management tools let you organize results into folders and areas of interest, and remote display options allow you to mirror results to a phone or tablet for added flexibility.

Rent the Flex NX today and bring clarity, speed, and confidence to your next project—without the long-term commitment.

| Stockage | 200 GB |

| Température de fonctionnement | -20°C to +50°C (-4°F to +122°F) |

| Indice de protection IP | IP65 |

| Puissance | Lithium-Ion battery |

| Dimensions | 25.3 x 13.2 x 18.9 cm (9.9 x 5.2 x 7.4 in) |

| Poids | 2.2 kg (4.9 lbs) including battery 2.4 kg (5.3 lbs) including battery and handle |

| Depth Range | NX25: 0-75 cm (0-30 in) |