Guide

Sound Level Meters: How They Work, Best Models & Industrial Applications

Sound level meters provide precise readings of sound pressure levels in decibels (dB) to help protect workers and maintain compliance with occupational noise standards.

→ Jump to the best sound level meters of 2025.

In industries as diverse as Oil & Gas, Manufacturing, Power Generation, Mining, and Chemical Processing, sound meters are essential tools for measuring and managing noise in industrial environments.

Why? Because, in all of these sectors, equipment like compressors, turbines, and pumps generate high noise levels that produce the need for vigilant environmental monitoring. Accurate sound measurements ensure compliance with OSHA and international noise exposure limits while helping identify mechanical issues or inefficiencies that could impact performance or safety.

Other common terms for sound level meters include:

- Noise meters

- Noise level meters

- Sound meters

- Decibel meters

- Noise-measuring instruments

In this guide we cover how sound level meters work, the best decibel meters on the market, and a lot more.

Use the menu to the right to jump around, or continue reading for the full guide.

Best Sound Level Meters for Sale and More [New for 2025]

Modern digital sound level meters have advanced well beyond simple handheld devices.

Today’s models offer data logging, real-time analysis, and software connectivity for easier compliance reporting and long-term monitoring. These capabilities make them indispensable for environmental health and safety (EHS) programs, maintenance planning, and regulatory inspections.

[Related read: Environmental Monitoring Tools & Equipment: 2025 Buyer’s Guide]

Below is one of the top sound meters on the market right now, followed by other noise-detecting devices made for environmental monitoring.

1. Casella CEL-633.A1.K1 Kit—Sound Level Meter

The CEL-633.A1.K1 is a handheld digital sound level meter for precise environmental and occupational noise surveys. It captures real-time sound pressure levels with flexible frequency and time weightings for accurate, repeatable results in industrial settings.

- Flexible measurement. Multiple frequency and time weightings for varied survey conditions.

- Data you can use. Onboard logging with easy transfer to PC for analysis and reporting.

- Field-ready display. Backlit, high-resolution screen for low-light environments.

- Smart calibration. Calibrator recognition with automatic level adjustment.

Rent the Casella CEL-633.A1.K1 Kit.

2. Casella CEL-350IS—Noise Dosimeter

The CEL-350IS is an intrinsically safe, wearable noise dosimeter for tracking a worker’s cumulative exposure over a shift. It clips to clothing and records dose, TWA, and time-history, giving safety teams the data needed for hearing conservation and OSHA compliance.

- Intrinsically safe. Built for hazardous locations in oil & gas, chemical, and industrial plants.

- Personal exposure data. Calculates common dose and TWA parameters with time-history.

- Lightweight & simple. Minimal setup; comfortable for all-shift wear.

- Auto-calibration. Works with standard acoustic calibrators for fast checks.

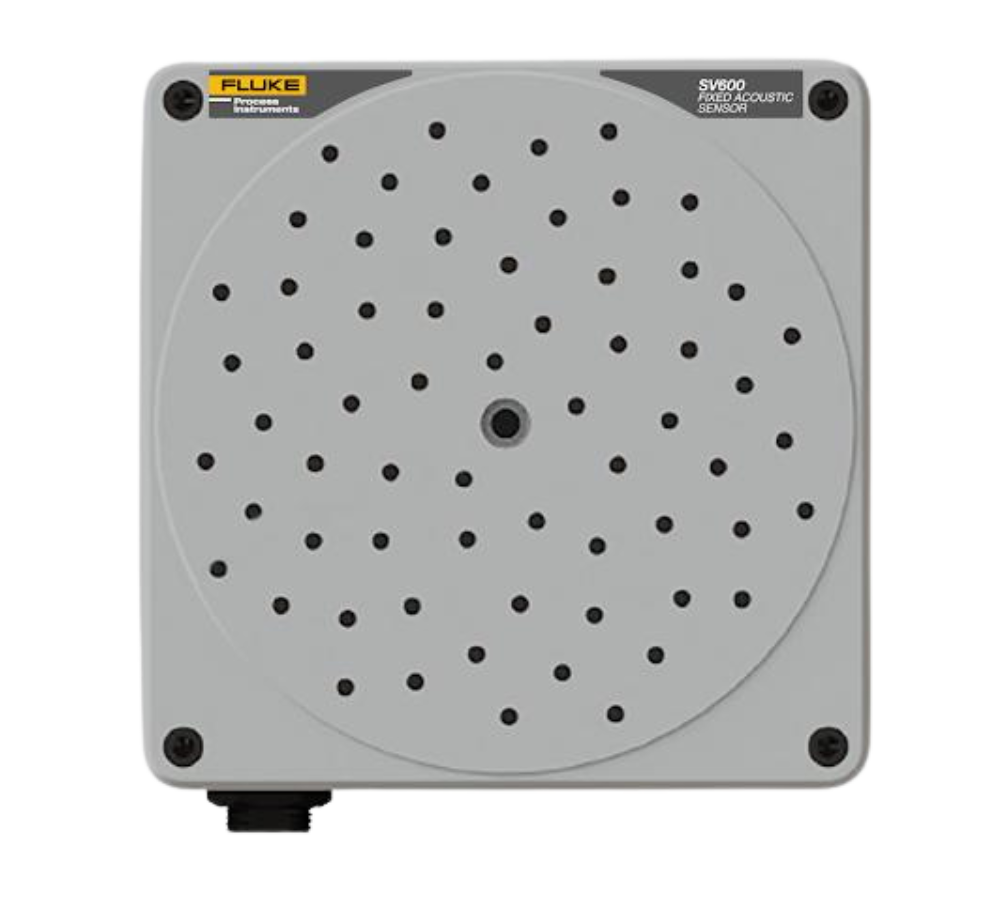

3. Fluke SV600—Acoustic Imager

The Fluke SV600 converts sound into a visual SoundMap, helping teams detect and locate compressed-air and gas leaks or mechanical anomalies in real time. It can be fixed-mounted or integrated with robotic platforms for automated rounds.

- Visual leak detection. Real-time acoustic maps highlight leak locations.

- Automation-ready. Can be integrated with mobile robots for routine inspections.

- Predictive insights. Helps identify abnormal sound signatures before failures.

4. Crysound 2623—Acoustic Imager

The Crysound 2623 is a handheld acoustic camera that localizes sound sources for fast diagnostics. It visualizes air, gas, and vacuum leaks and supports partial discharge detection for electrical assets.

- Beamforming microphone array. Pinpoints sound sources with high confidence.

- Leak & PD detection. Supports gas-leak and electrical partial-discharge workflows.

- On-device reporting. Capture images/video and generate reports quickly.

- Rugged build. Aluminum-alloy housing for industrial environments.

Buy or rent the Crysound 2623.

5. Crysound 8124—Acoustic Imager

The Crysound 8124 combines a high-density microphone array with a high-resolution display to visualize leaks and electrical discharge across complex assets. It’s designed for larger inspection areas and long shifts.

- High-density array. 200-microphone design for long-range, precise localization.

- Wide bandwidth. Up to 100 kHz for faint leak and PD detection.

- Dual-mode reporting. Generates acoustic (and optional thermal) image reports.

- Field-ready display & power. 1920×1200 screen; up to 5 hours of operation.

What Is a Sound Level Meter?

A sound level meter is a precision instrument used to measure the intensity of sound in decibels (dB), the standard unit for quantifying sound pressure levels (SPL).

Also called a noise meter or sound meter, it converts variations in air pressure caused by sound waves into electrical signals that can be displayed, stored, or analyzed.

Sound level meters form the foundation of industrial noise management programs, providing the data needed to ensure compliance with OSHA and ISO/IEC standards.

In high-noise environments such as refineries, manufacturing facilities, and construction zones, these instruments help safety professionals identify hazardous noise levels from compressors, turbines, and other heavy equipment.

The 4 Core Components of a Sound Meter

Every sound level meter captures and interprets sound data with these core components:

- Microphone. Detects acoustic pressure variations and converts them into electrical signals.

- Preamplifier. Strengthens the signal for accurate processing.

- Signal processor. Converts the analog signal into digital data and applies frequency/time weightings.

- Display or interface. Shows readings in real time, often with onboard logging or transfer capability.

Professional sound level meters include selectable frequency and time weightings to align with regulatory measurement methods. These allow readings to reflect how the human ear perceives sound or to meet specific industrial standards.

Although the term “decibel meter” is sometimes used informally, true sound level meters go beyond simple dB readings. They provide weighted, averaged, and traceable measurements that meet recognized international standards for accuracy and repeatability.

Sound Level Meters vs. Other Sound-Based Inspection Equipment

Sound level meters are the most commonly used tools for noise measurement and compliance. But they’re part of a broader family of acoustic inspection and diagnostic instruments.

In industrial environments, engineers and EHS professionals often use multiple tools together—some for environmental noise monitoring, others for worker exposure or detailed acoustic imaging.

Understanding how these instruments differ helps determine which is best suited for a given task.

Comparison of Sound Level Meters and Other Sound Measurement Tools

| Tool | Primary Function | Common Industrial Uses |

|---|---|---|

| Sound Level Meter | Measures instantaneous sound pressure levels (SPL) in decibels (dB) for environmental or area noise assessments | Compliance surveys, machine noise checks, acoustic performance benchmarking |

| Noise Dosimeter | Worn by workers to measure and record cumulative personal noise exposure over time | Hearing conservation programs, OSHA compliance, personal exposure tracking |

| Integrating Sound Level Meter | Calculates average sound energy (Leq) across a measurement period to capture fluctuating noise levels | Long-term monitoring, noise mapping, environmental trend analysis |

| Sound Analyzer | Performs detailed frequency and time-history analysis for complex acoustic diagnostics | Engineering noise control, spectral analysis, tonal identification |

| Vibration Meter | Measures vibration amplitude and frequency, often correlated with noise levels to detect mechanical faults | Rotating equipment monitoring, bearing diagnostics, predictive maintenance |

| Acoustic Camera / Microphone Array | Visualizes sound intensity and source location using multiple microphones and beamforming software | Leak detection, electrical discharge localization, environmental noise visualization |

How to Use These Tools Together

Integrating multiple sound-measurement tools creates a comprehensive acoustic monitoring program that links personal exposure, environmental noise, and mechanical source data.

- Start with Sound Level Meters to establish baseline area readings and identify high-noise zones.

- Use Noise Dosimeters to measure personal noise exposure across full shifts and determine compliance with OSHA 1910.95.

- Deploy Integrating Sound Level Meters for time-averaged or continuous Leq assessments across variable environments.

- Apply Sound Analyzers to isolate problem frequencies and guide engineering noise control measures.

- Use Acoustic Cameras or Microphone Arrays to visualize and pinpoint noise sources, such as compressed air leaks or electrical arcing.

- Pair with Vibration Meters to correlate mechanical vibration with acoustic signatures for predictive maintenance and fault detection.

Coordinating these instruments ensures a complete noise assessment—from personal exposure to environmental impact—helping teams diagnose issues faster, reduce risk, and maintain regulatory compliance.

How Do Sound Level Meters Work?

At the core of every digital sound level meter is a precision microphone that detects acoustic pressure variations. When sound waves reach the microphone diaphragm, they cause tiny movements that generate an electrical signal proportional to the pressure change.

That signal is then passed to a preamplifier, which boosts it for analysis without introducing distortion. The result is a clean, measurable signal that accurately represents the acoustic environment.

Filtering and Weighting

Once conditioned, the signal moves to the instrument’s processor. Here, the meter applies frequency and time weighting filters to ensure readings align with human hearing or meet regulatory standards.

The most common filters are:

- A-weighting. Mimics the human ear’s response to mid-frequency sounds and is standard for occupational noise monitoring.

- C-weighting. Captures lower frequencies common in industrial and environmental noise.

- Z-weighting. Provides an unweighted, flat frequency response for full-spectrum acoustic analysis.

Time weighting further refines how the meter responds to changes in sound levels:

Types of Sound Level Meters

Sound level meters come in several types, each designed for specific measurement needs and accuracy standards.

Each type serves a distinct purpose—from precise regulatory analysis to everyday plant monitoring. Understanding these differences ensures the right tool is used for every acoustic measurement challenge.

Here are the different types of sound meters.

1. Class 1 Sound Level Meters

Class 1 sound level meters meet the highest accuracy requirements defined by IEC 61672-1:2013 standards. They offer the most precise frequency and time-weighted measurements, with tight tolerances across a wide frequency range.

These instruments are used for formal compliance testing, environmental surveys, and laboratory-grade noise analysis where precision and repeatability are critical.

- Accuracy. ±1.0 dB or better across 20 Hz to 20 kHz.

- Applications. Environmental noise studies, research, calibration labs, and regulatory testing.

- Example. Casella CEL-633.A1.K1 Kit available from MFE.

2. Class 2 Sound Level Meters

Class 2 sound level meters are designed for general-purpose industrial monitoring.

They comply with the same IEC 61672-1 standard but with looser tolerances, making them cost-effective and durable for routine fieldwork.

Although slightly less precise than Class 1 models, Class 2 meters remain suitable for most workplace noise surveys and maintenance programs.

- Accuracy. ±2.0 dB, typically covering 20 Hz to 8 kHz.

- Applications. Occupational noise checks, machinery noise control, and preventive maintenance inspections.

3. Integrating Sound Level Meters

Integrating sound level meters measure the total sound energy over time, expressed as Leq (Equivalent Continuous Sound Level).

These devices are ideal for environments where noise fluctuates throughout the day, providing a true average exposure level.

They combine spot-measurement capability with long-term averaging functions to deliver a more complete picture of acoustic conditions.

- Accuracy. Same class tolerances as the base model (Class 1 or 2).

- Applications. Shift-based exposure assessments, long-term environmental noise logging, and acoustic trend analysis.

4. Logging or Data-Recording Sound Level Meters

Logging sound level meters include onboard memory and real-time clocks to store continuous or periodic measurements.

They can capture detailed time histories, making them valuable for compliance documentation and multi-day studies.

Data can be downloaded to PC software for graphing, analysis, or report generation.

- Accuracy. Based on meter class; logging adds data traceability, not measurement change.

- Applications. Environmental compliance, round-the-clock industrial monitoring, and noise mapping.

5. Digital Sound Level Meters

Modern digital sound level meters use advanced processors to enhance accuracy and user experience. They often feature color displays, intuitive menus, and connectivity options like USB, Bluetooth, or cloud integration.

Their versatility makes them ideal for safety officers and engineers who require reliable data and efficient workflows.

- Accuracy. Matches IEC Class 1 or Class 2 standards depending on model.

- Applications. Routine industrial surveys, EHS documentation, and data-driven compliance programs.

- Key advantages. Faster setup, streamlined reporting, and integration with analysis software.

6 Industries That Use Sound Level Meters

Sound level meters are vital tools across heavy industries, where controlling noise exposure and verifying compliance protect both people and assets.

Programs often combine handheld sound level meters for spot checks with logging or integrating models for shift-long exposure studies and environmental impact monitoring.

Here are six sectors that rely on sound level meters for safety, diagnostics, and regulatory confidence.

1. Oil, Gas & Petrochemical

Process equipment such as compressors, pumps, and flare stacks generate sustained and impulsive noise that must be monitored for OSHA and EPA compliance.

Sound level meters in oil and gas operations help teams:

- Measure equipment noise during turnarounds and maintenance.

- Verify compliance with OSHA 1910.95 exposure limits.

- Assess noise propagation near process units and loading areas.

- Correlate noise readings with vibration and leak-detection data.

2. Power Generation & Utilities

Turbine halls, substations, and generator enclosures produce high sound pressure levels that affect worker safety and equipment health.

Sound level meters in power facilities support:

- Routine sound mapping around turbines, boilers, and transformers.

- Monitoring of hearing protection zones per ISO 9612 and OSHA guidance.

- Condition-based maintenance through noise trend analysis.

- Community noise assessment at plant boundaries.

3. Manufacturing & Metalworking

From stamping and machining to foundry and fabrication lines, industrial noise can exceed safe limits without proper control.

Sound level meters in manufacturing environments are used to:

- Measure noise levels at operator stations and production cells.

- Validate effectiveness of acoustic enclosures and dampers.

- Conduct pre- and post-maintenance checks on fans and presses.

- Document compliance with corporate or regulatory exposure policies.

4. Construction & Infrastructure

Heavy equipment, pile driving, and demolition create variable and high-intensity noise that must be monitored to protect workers and nearby communities.

Sound level meters in construction applications help teams:

- Record peak and average levels for OSHA compliance reports.

- Measure perimeter noise to address public or municipal concerns.

- Trigger mitigation measures such as barriers or work-hour limits.

- Correlate noise events with task logs and weather data.

5. Mining & Quarrying

Mining operations involve continuous exposure to high-energy noise from crushers, drills, and haul trucks.

Sound level meters in mining are applied to:

- Monitor operator exposure for drillers, loaders, and crusher attendants.

- Map sound profiles across open pits, conveyors, and processing plants.

- Evaluate effectiveness of acoustic controls and hearing protection.

- Support long-term environmental noise baselines around sites.

6. Renewables & Wind Energy

Wind farms and renewable facilities require ongoing acoustic monitoring to assess both worker exposure and environmental impact.

Sound level meters in renewables are used for:

- Measuring turbine-blade and gearbox noise during maintenance.

- Baseline and post-installation sound surveys for community acceptance.

- Comparing operational noise data against manufacturer specifications.

- Coordinating acoustic data with vibration and ultrasonic inspection results.

Choosing the Right Sound Level Meter

Trying to find the right sound meter for your needs? This section is designed to help you navigate the process.

Whether evaluating workplace noise, assessing equipment performance, or conducting environmental surveys, the right tool delivers consistent, defensible results.

Here are the most important factors to consider when choosing a noise meter:

- Accuracy and Class Rating (Class 1 vs. Class 2). Class 1 meters provide the highest precision, meeting IEC 61672-1 standards with ±1 dB accuracy across a broad frequency range. They’re ideal for regulatory testing, research, and environmental surveys. Class 2 meters, while slightly less precise, are rugged and cost-effective for general industrial monitoring.

- Measurement Type. Determine whether you need spot measurements, time-averaged (integrating) readings, or continuous logging. Integrating and logging meters record noise trends over time, offering deeper insights into fluctuating sound environments.

- Environmental Conditions. Consider the measurement environment. High temperatures, humidity, or strong air movement can affect readings. Look for models with environmental compensation or weatherproof accessories when working outdoors.

- Frequency and Time Weighting Options. Choose meters that support A, C, and Z frequency weighting, along with Fast, Slow, and Impulse time responses. These functions ensure data meets regulatory requirements and accurately reflects how humans perceive noise.

- Connectivity and Data Management. Many digital sound level meters include USB or Bluetooth connectivity for easy data transfer. Software integration allows automatic report generation and trend analysis—key for compliance audits and ongoing monitoring programs.

- Durability and Intrinsic Safety. For environments such as refineries or chemical plants, intrinsically safe designs prevent ignition risks. Rugged housings and shock-resistant cases protect meters from vibration and dust exposure in harsh field conditions.

When in doubt, match the tool to the task. A high-accuracy Class 1 sound level meter suits formal testing and environmental impact studies, while a compact Class 2 digital meter is often sufficient for daily workplace monitoring.

Sound Level Meter Selection Chart

Select a sound level meter based on your objective, accuracy requirements, and environment.

- If your goal is regulatory or environmental compliance, choose a Class 1 or integrating sound level meter.

- For routine workplace monitoring, a Class 2 or logging sound level meter usually provides sufficient accuracy and durability.

This chart summarizes the main sound level meter types to help you identify the right solution for your application.

| Type | Accuracy | Measurement Purpose | Duration / Mobility | Data Output | Environment | Typical Use Cases |

|---|---|---|---|---|---|---|

| Class 1 Sound Level Meter | ±1 dB, IEC 61672-1 Class 1 | High-precision measurements for compliance and research | Tripod or handheld; stationary use preferred | Time-history, frequency analysis, Leq, statistical data | Labs, outdoors, environmental studies | Regulatory testing, acoustic surveys, baseline monitoring |

| Class 2 Sound Level Meter | ±2 dB, IEC 61672-1 Class 2 | General-purpose workplace and equipment noise checks | Portable, handheld | Instantaneous or averaged SPL readings | Industrial facilities, maintenance shops | Routine noise surveys, maintenance inspections, PPE validation |

| Integrating Sound Level Meter | Same class tolerances as base model (Class 1 or 2) | Measures total sound energy over time (Leq) | Short-term or shift-based | Average exposure, TWA, peak and trend analysis | Dynamic environments, process areas | Shift-based exposure studies, fluctuating noise profiles |

| Logging / Data-Recording Sound Level Meter | Matches base class accuracy | Continuous or periodic logging with timestamps | Stationary or semi-portable | Time-stamped logs, exportable CSV/JSON | 24/7 operations, compliance sites | Environmental audits, community impact assessments, long-term monitoring |

| Intrinsically Safe / Ruggedized Model | Class 1 or 2 with IS certification | Noise monitoring in hazardous or high-vibration areas | Handheld or wearable | Standard SPL or logged data | Oil & gas, chemical, or mining operations | Hazardous-area safety checks, confined space monitoring |

Selection Criteria Checklist

Use this checklist to identify the right sound level meter for your work environment and regulatory obligations.

Sound Meter FAQ

Here are answers to the most commonly asked questions about sound level meters.

What is the difference between a sound level meter and a decibel meter?

A sound level meter is a precision instrument that measures sound pressure levels using standardized weighting filters and response times to mimic how humans perceive sound. A “decibel meter” is a general term often used for basic devices or smartphone apps that provide approximate readings. Professional sound level meters—such as those offered by MFE Inspection Solutions—are engineered to meet IEC 61672 and ANSI S1.4 standards, ensuring calibrated accuracy for industrial and regulatory use.

What does a sound level meter measure?

Sound level meters measure sound pressure levels (SPL) in decibels (dB). They record how much acoustic energy exists in an environment and apply weighting filters such as A, C, or Z to match regulatory or perceptual standards. These measurements are used to evaluate workplace noise exposure, equipment performance, and environmental compliance.

Where are sound level meters used?

Sound level meters are used across industrial, commercial, and environmental settings. In Oil & Gas facilities, they help monitor compressors and pumps; in manufacturing, they verify machinery compliance with occupational noise limits. They’re also used in power plants, data centers, construction zones, and community noise studies to ensure safety and compliance with OSHA and ISO/IEC standards.

Can I use my phone as a sound level meter?

While smartphone apps can provide rough noise estimates, they are not suitable for compliance-grade measurements. Consumer microphones lack the calibration and frequency response required for accurate industrial readings. For defensible data, use a certified Class 1 or Class 2 sound level meter from a trusted source like MFE Inspection Solutions.

Which sound level meter is best for industrial use?

The best sound level meter depends on the required precision and application. A Class 1 sound level meter is recommended for regulatory inspections, environmental surveys, and engineering diagnostics, while Class 2 meters are suitable for daily workplace monitoring. MFE offers both types, along with noise dosimeters and acoustic imagers for advanced assessments.

What is a digital sound level meter?

A digital sound level meter uses advanced signal processing and onboard memory to record, store, and analyze data automatically. These meters often include USB or Bluetooth connectivity, allowing technicians to download data and generate reports instantly. Digital models are popular in industrial environments for their accuracy, durability, and ease of use.

What is a Class 1 sound level meter?

Class 1 sound level meters are the most accurate instruments available, meeting ±1 dB tolerances across a broad frequency range. They’re certified under IEC 61672-1 standards and used when measurement precision is critical—such as in environmental compliance, laboratory testing, and engineering-grade inspections. These meters are ideal for organizations that require traceable, defensible acoustic data.

Do sound level meters need calibration?

Yes. Calibration ensures measurement accuracy and regulatory compliance. Field calibration with an acoustic calibrator should be performed before and after every use, while laboratory calibration is typically required annually. MFE Inspection Solutions provides calibration assistance and guidance to maintain traceable, audit-ready performance across all instruments.

How often should I take noise measurements at my facility?

Noise levels should be assessed regularly—at least annually for ongoing operations, and whenever new equipment, processes, or work schedules are introduced. For high-noise environments, continuous or periodic monitoring may be necessary to maintain OSHA compliance and protect worker hearing.

What’s the difference between a sound level meter and a noise dosimeter?

A sound level meter measures environmental or area noise at specific locations, while a noise dosimeter measures an individual worker’s personal noise exposure over time. Both are essential for comprehensive noise management. MFE provides both instruments to help industrial clients monitor work areas and personal exposure for complete compliance coverage.